The OT-62 TOPAS (Transportér Obrněný Pásový) was in the cold war, the main Polish-Czech hamphibious tracked armoured personnel carriers (APC). It jointly developed in 1959-62 as an equivalent to the Soviet BTR-50. The vzor 62 had many difference with the Soviet vehicle, and arguably more variants and derivative. It was also exported and saw action in several conflicts.

After joining the Warsaw Pact in 1955, the Czech republic started to start as alternatives to its mostly fleet of ex-German vehicles plus its own domestic half-track Tatra OT-810 derived from the Sd.Kfz.251. The latter were already partially produced during the war by Škoda Pilsen, Mürzzuschlag-Bohemia, Česká Lípa as well as the SdKfz.250 (Demag D-7) postwar, in reunified Czechoslovakia plus some International Harvester M5 halftracks from Soviet lend-lease supplies.

The new army in 1947 needed new equipment, the supply of American vehicle was over, and the Soviets were reluctant to share anything. Many trophy German vehicles were pressed into service as well as the SdKfz 251 and 250 with the 251 factory redesignated HKL-6 and vehicle production resumed under the name "Hakl", officially OPp3N sent to border guard units, some with the Tatra T-928-3 engine (HKL-6p) from 1952.

Some eengineers were toying with full-lenght tracked APCs such as a possible adapation of WW2 German "Kätzchen" project based on the 38t chassisn but it appeared a bit small, and in 1951, there were still 736 halftracks, most being the HKL-6p and by 1957, 630 (476 HKL-6p) while development of the OT-810 authorized in 1948 by Soviet authorities after local staff preferred it to the all wheeled BTR-152 but real development started in 1952 from the HKL-6p, stopped in 1954, resumed in 1956 with different engine, new body shapes, fully covered infantry compartment, 10 made in 1958-1959, accepted as "Obrněný transportér" in 1959 and some 1,140 were made between 1960 and 1962 in Slovakia.

It was not popular, being heavier than the original, hard to control, with a cramped, hot infantry compartment and a difficult maintenance. It was soo poor as nicknamed by the troops "Hitlerova pomsta" ("Hitler's Revenge"). They joined the warehouses for a long time as soon as an alternative was available.

In the spring of 1956, the Commander of the Tank and Mechanized Troops submitted to the Technical Administration of the General Staff preliminary technical and tactical requirements for a 12 t amphibious APC (something the OT-810 wasn't, neither NBC). Requirements received annotations and recommendations by Soviet military and technical experts by early 1957. Modified technical and tactical requirements were reworked in Czech military academies, went through the Ministry of General Engineering, R&D Centre J. V. Stalin in Martin and two preliminary designs drawn up in Turiec: > TOPAS 1, two engines

> TOPAS 2 one engine.

The latter was selected and completed by the summer of 1958 and consulted by Stalingrad plant team which criticized the excessive complexity and instead pressed to start again on a modernization of the existing Soviet BTR-50PA. This was approved by September 1958 while licensing documentation translated into Czech, was asked for, and soon three BTR-50PA were sent by rail. Deadlines were pushed down by 5 months, but this enable to modernise the Soviet design with critical changes in layout. The original engine was now turbocharged, transmission a new five-speed gearbox with combined directional gear train, new torsion bars, new drive wheel, a new commander's turret, new gunner's turret adapted to mount the Czech vz. 59. Two prototypes emerged from these works by October 1959 and summer 1960, tested locally by the autumn.

So by 1960 Czechoslovakia had two "modernized BTR-50" that could also interest the Soviet Union for future upgrades. The new tracked armoured personnel carrier for the Czechoslovak army was also now aimed as well for Poland, which looked after a similar vehicle (Ludowe Wojsko Polskie or LWP). Adapation work started at the same time in 1958 at Wojskowa Akademia Techniczna (WAT) (Polish Military Technical Academy) and Wojskowy Instytut Techniki Pancernej i Samochodowej, the Military Institute of Armour and Car Technology, and a first prototype completed in 1962. It passed trials and was accepted under the acronym TOPAS. Production started at Podpolianske Strojárne.

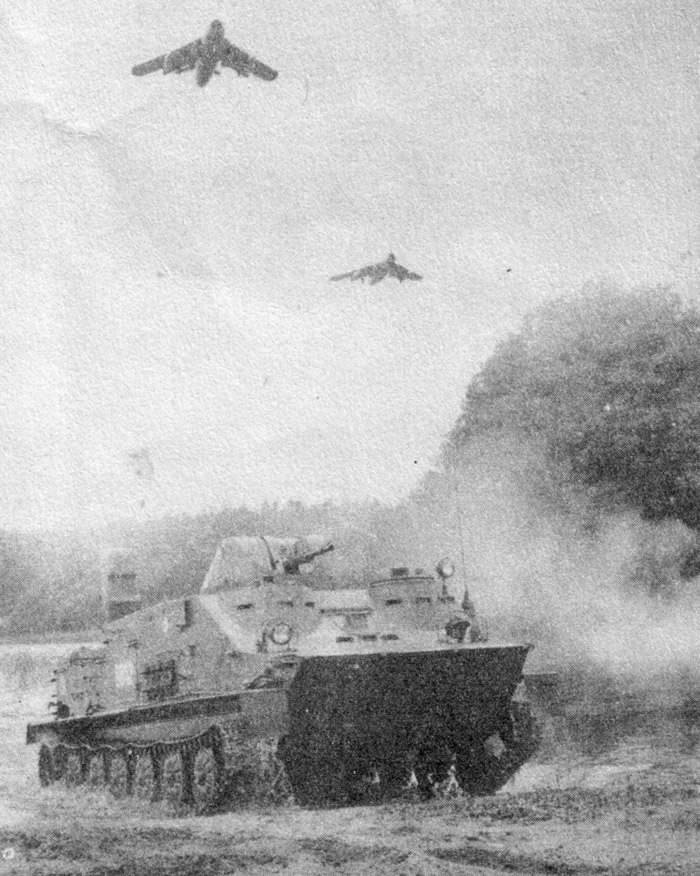

Military trials in 1961 meanwhile were divided into static design verifications to match the TTZ, and tactical exercises modelled after the need of the 1st Czech Armoured Division as well as an added set of riverine, lake and sea trials. In the latter the vehicle proved stable, buoyant enough, stable in navigation and not lowered too much even when loaded with the recoiless Czech 85 mm gun vz.52, or even carrying a GAZ-69. On land, the vehicle was used for towing and transporting various ordnances, notably the 82 mm BzK vz. 59, 120 mm mortar vz.42N, or two mortars vz. 52 including ammunition. It went as far as firing the mortars underway. All tests were satisfactory, and went beyonf requirement as usual in Soviet practice.

The OT-TOPAS was greenlighted by the procurement bureau by November 1962 and received the official designation OT-62. Production was setup to start in 1963 and was schedule to run until 1968 at PPS Detva to cover the need of the Czech army, a total of 890 vehicles when the manufacturing ceased. They provided for the sixties and until the eighties, the bulk of Czech motorized artillery regiments associated with Czech tank divisions. The first vehicles started to be replaced by the late 1970s, and many joined depots, replaced by the BMP-2.

The basic Polish People's Army vehicle was unarmed and so Wojskowa Akademia Techniczna (WAT) bureau developed an armed variant, designing a new turret placed which was placed on top of the superstructure, in the middle. The other Polish TOPAS variant from the Military Institute of Armour and Car Technology was the WPT-TOPAS, used for technical support. But the OT-62 was also built in Czechoslovakia.

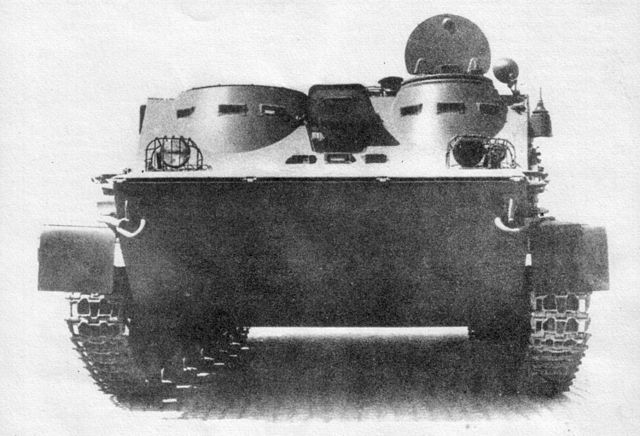

Like the BTR-50PK, the OT-62/TOPAS uses very same flat and vaguely boat-shaped underbelly hull. The layout is the same also, engine at the rear, superstructure in front of the vehicle. The entire hull is made of all-welded rolled steel, and the crew compartment is at the front, followed by a small troop compartment, center and engine compartment at the rear. The troop compartme it quite cramped and still is roomy enough for two benches runing across the full width, for sixteen men total eight per side.

Access and exit in particular in this type is specific, by climbing over the sides of the hull, going through two rectangular roof hatches but more than the BTR-50, the OT-62/ TOPAS has side hatches on both superstructure sides, less reisky under fire than rectangular roof hatches leaving the troops exposed to enemy fire.

The driver is seated in the center-front of the hull, under a dome shaped forward post, topped with three vision blocks and periscopes above, at the top of the sloping glacis plate. By night the TVN-28 night vision is installed for safe driving, one the center periscope, giving a clear range of 60 meters. The driver could access via a small hatch opening upwards and not too prominent for secured day driving while buttoned up in safe areas. For exit, he probably uses normally the side hatches in the superstructure behind, of has his own emergency hatch anyway below, useful in case of turnover, and available to a all crew members.

The commander is seating on the left side od the structure, and is also given three vision blocks, periscopes in a small projecting bay. He also has a cupola with vision blocks only facing forward. The cupola is also a hatch opening forward, on top of projecting bay, locked vertically to keep it up when underway on bumpy terrain. This is probably the most distinctivepoint about the vehicle compared to the BTR-50: Two side hatches and two projecting bays as on the BTR-50PU, with reshaped bays. The second projecting bay had on top a cupola replacing the additional BTR-50PK rectangular roof hatch.

The OT-62 is powered by the PV-6 6-cylinder inline diesel engine rated for 300 hp (220 kW) at 1,800 rpm, for a road speed of 60 km/h, cruising range of 450 km to 550 km depending on terrain and load. On trials, the vehicle was seen able to cross 0.9 m high vertical obstacles, gap 2.8 m wide trenches, climb 38° gradients and ford any body of water without preparation but raising in case the trim vane forward.

The drive train is generally similar to the PT-76 light tank. There are six evenly spaced cast/stamped large rubber-tired road wheels on either side, single pin tracks, rear drive sprocket and front idler. Due to the sprocket and transmission being compacted at the rear, this keeps the vehicle's profile low. The road wheels are not only stamped, they are hollow and relatively thin for extra buoyancy, with some studied of the time stating as much as 30% increase. Thius drivetrain does not provides track-return rollers.

The suspension system comprises torsion bar suspensions for all axles, but the first and last roadwheels axles are doubled on hydraulic shock absorbers. The steel single pin tracks are going in between roadwheels (the simplest, cheapest configuration) comprising a thread of 96 chain links each. The vehicle has no skirt per se, but a small and thin, horizontal skirt over each track, which is barely visible.

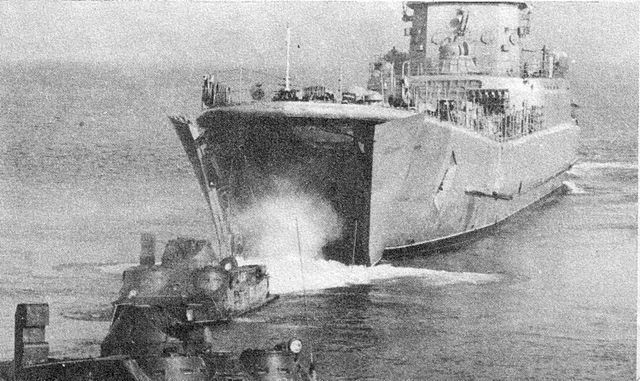

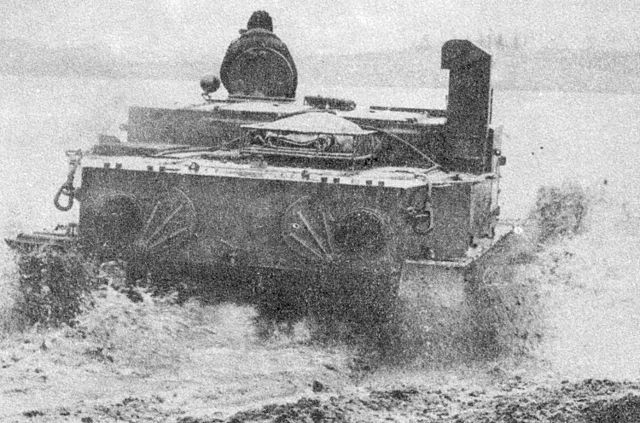

The amphibious caracteristics are helped first by the buoyancy offered by the wide and flat, boat-shaped hull, completely watertight, shaped for minimal resistance afloat. For fording or swimming, the driver activates the two electric bilge pumps, erect the trim vane as well as switching the periscope to the swimming one, much taller to see above the trim vane underway. In case the crew could activate an internal backup manual bilge pump in emergency. These bilge pumps had been tested and are energy-independent to function even if the vehicle was hit and engine cut. Propulions is ensured by two hydrojets, either side of the hull.

There are also additional assistant water-jet entrances on either sides and over the last road wheels. This is bsically the same system as on the BTR-50 and PT-76. For extra agility, rear waterflow exits receives rubber lids, fully or partially closed to redirect the water stream into the forward-directed side exits thus enabling the vehicle to turn on itself when swimming or go in reverse. Both right and left water-jets can either suck or push out for extra agility, as designed by N. Konowalov. The only issue with the design is to tackle any rough seas. It had a low freeboard of 15-20 cm, but compensating by using a tailored snorkel mount located on the right side of the front of the engine deck.

In addition to its night vision sights, the TOPAS is also given an IR driving light close to standard lights forward on the nose, and an IR searchlight located on the left side, but it can be swapped. On the BTR-50 it was on the right side, superstructure front but moved on the OT-62 close to the commander's cupola. Each side are giveen hooks and attachement points for shovels on either side, front, pickaxes on the superstructure and there is also a stowage bucket centrally in the front of the engine deck.

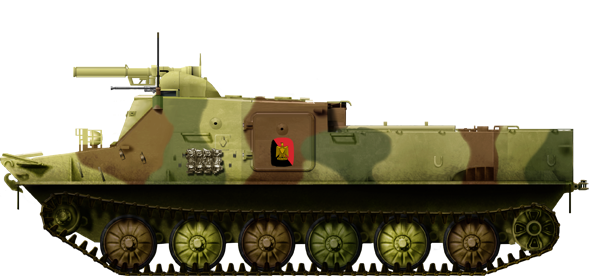

Polish TOPAS 2AP and its KPVT armed turret.

The basic APC was unarmed, except for the infantry aboard personal weapons, mortars, ATGMs and MANPADS. However this was seen as lacking the Poland notably pressed for the adoption of a turret. On the Czech size was developed the OT-62B, caracterized by a small rotating turret placed on top of the second projecting bay (replacing the cupola). It was fitted with a mount for the 7.62 mm Vz. 59T general purpose machine gun. More, a cradle like system was installed alongside to fire also the 82 mm T-21 "Tarasnice" recoilless gun. This was an external, one shot mount and needed a sortie to reload it, exposing the one doing it to enemy fire...

Before the age of internally aimed automatic ATGMs, this was a solution. 5-10 rounds were carried for the 82 mm T-21 "Tarasnice". The Czech antitank capabilities were translated into Poland by Ludowe Wojsko Polskie as the TOPAS-2A. The T-21 fires 82 mm grenades with high-explosive fragmentation (HE-F) warheads. The gun had a day sight with fixed 1.48x magnification, 1,800 metres range and at best, 10rpm in this configuration, although it could have been fitted with 6-round magazines. Traverse was very limited here, but it had a -5 +22.5° elevation.

But the most heavily armed without doubt was the OT-62D, which keeps the armament of the OT-62B but with a 82 mm Bzk vzor 59 recoilless gun installed complete (with its wheeled undercarriage) on the rear deck, to be easily dismounted or fired direbtly on the move. The latter is even more intended as anti-tank support. The vz.59 had a much longer barrel and muzzle velocity (50 m free behind !), 12.7mm ZH 59 spotting rifle for great accuracy and its HE shell however can still defeat 250 mm RHA. For artillery, range is 6,000m.

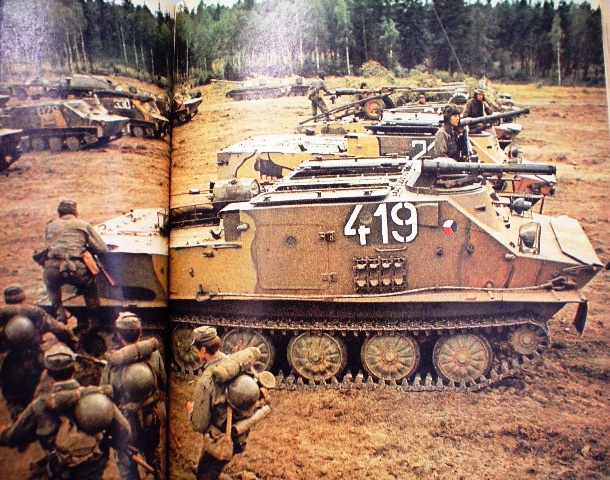

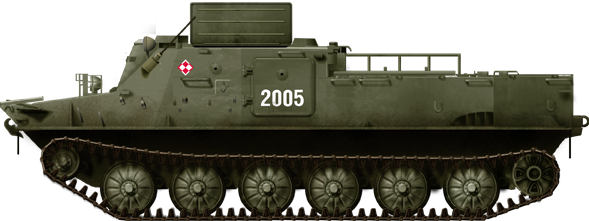

The Polish variant TOPAS 2AP came into two "favours" and are equally well armed. The basic version is the heaviest, being modified with a central one-man WAT turret sporting a 14.5 mm KPVT heavy machine gun, mounted coaxially with a 7.62 mm SGMT coaxial medium machine gun. Same turret as on the SKOT-2AP. The 7.62 mm SGMT was later replaced by the more modern Soviet 7.62 mm PKT general purpose machine gun. The top rectangular roof hatches could not be kept due to the turret ring and were moved to the sides-top of the superstructure. With three crew members, bulk of the turret basket and associated ammunition, the rear compartment lost four seats, from sixteen to twelve. With 16 tonnes fully loaded, the vehicle still should have enough buoyancy to perform on water.

The second "flavour" is even more radical as the rear compartment is gutted and infantry replaced two 82 mm mortars served by 8 mortar crew members. The 82 mm mortar has a rate of fire of 25 rounds per minute and 50-100 mortar rounds are carried. This made the vehicle (unofficially TOPAS 2APM) no longer an APC but a support vehicle, although without antitank capabilities. It should be noted that the latter was provided by the TOPAS 2A.

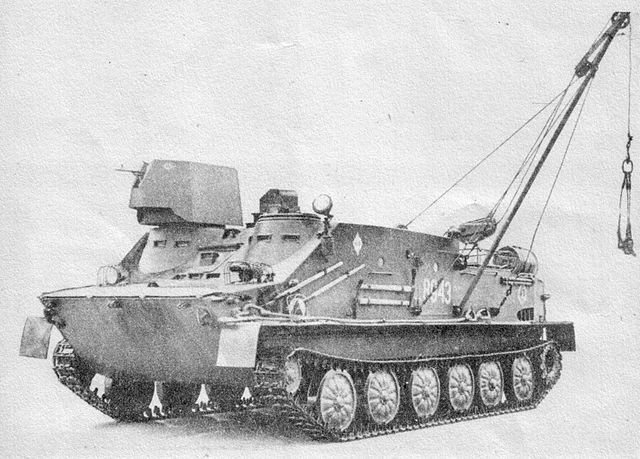

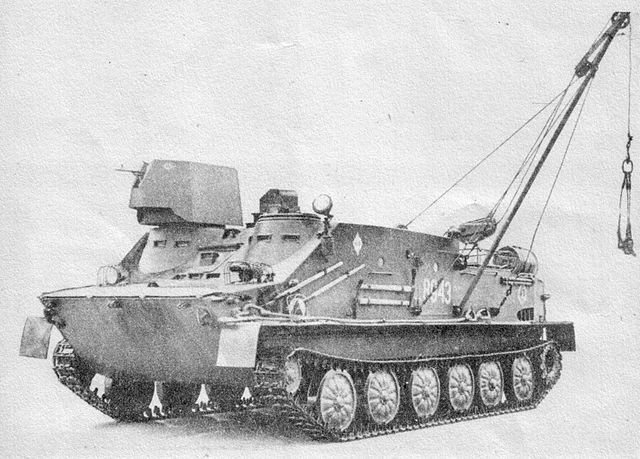

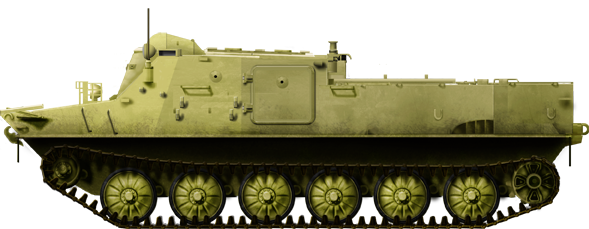

Polish TOPAS WPT salvage vehicle, differing from the Czech DTP-62.

Poland also used a similar signals/command vehicle but was the only one to develop a completed salvage vehicle, more advanced than the Czech DTP-62 but not adopted by Czechoslovakia. This Polish version is called Wóz Pogotowia Technicznego, abbreviated as WTP for "Technical Support Vehicle". It is tailor to salvage other TOPAS and PT-76 light tanks left damaged on the battlefield, and those bogged down or trapped when their amphibious ability fails. The intention was to retreive them thanks to a set of powerful winches, two them to the rear for field repairs, including medical help for potential wounded crew members in the troop compartment. It is equipped with the following:

-Main winch, maximum capacity 2.5 tonnes, 600 m cable

-Manual crane, maximum capacity 1 tonne but movable to be fixed around the vehicle

-Stowage boxes with tools, devices and field repair equipments

-Welding set, pontoon, divers equipments.

-Single PK general purpose machine gun (right side cupola, v-shaped shield).

TOPAS WPT

OT-62 in Latrun

IDF captured an estimated 80-120 Syrian and mostly Egyptian Czech-built OT-62s in 1967. Under the name OT-62A the upgrade was limited to fitting two israeli designed machine gun mounts, each in front of a hatch on top of both cupolas, for the Browning M1919A4. This was a quick and cost-efficient standardization. IDF vehicles were withdrawn from service in 2002, at least one surviving in a museum.

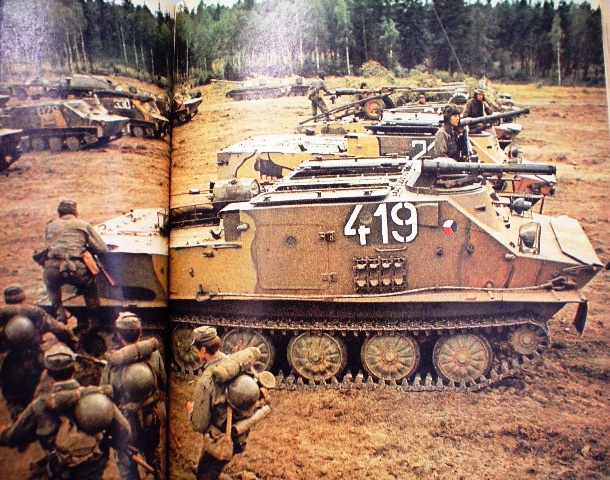

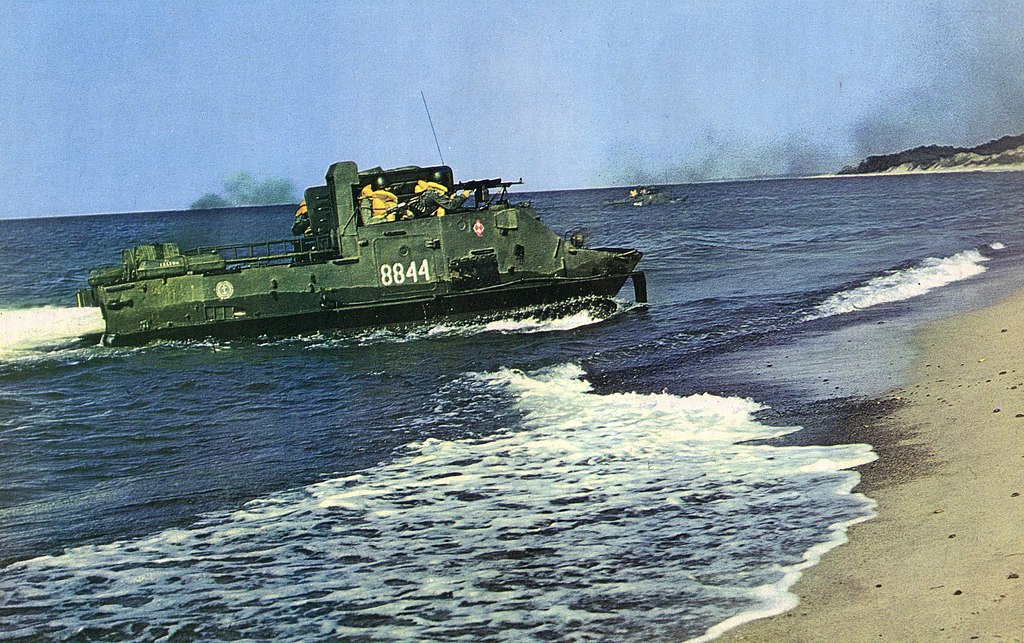

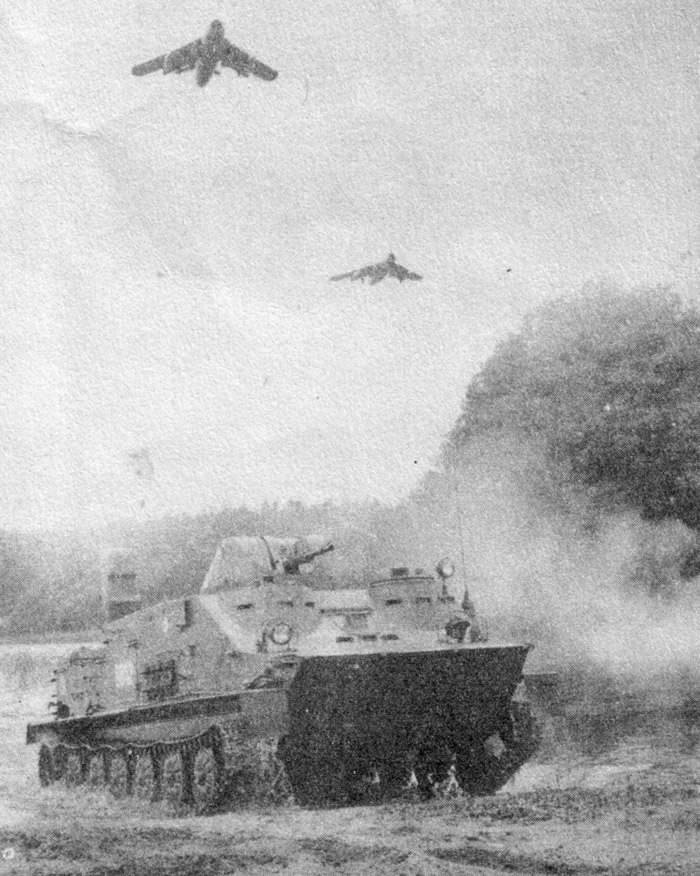

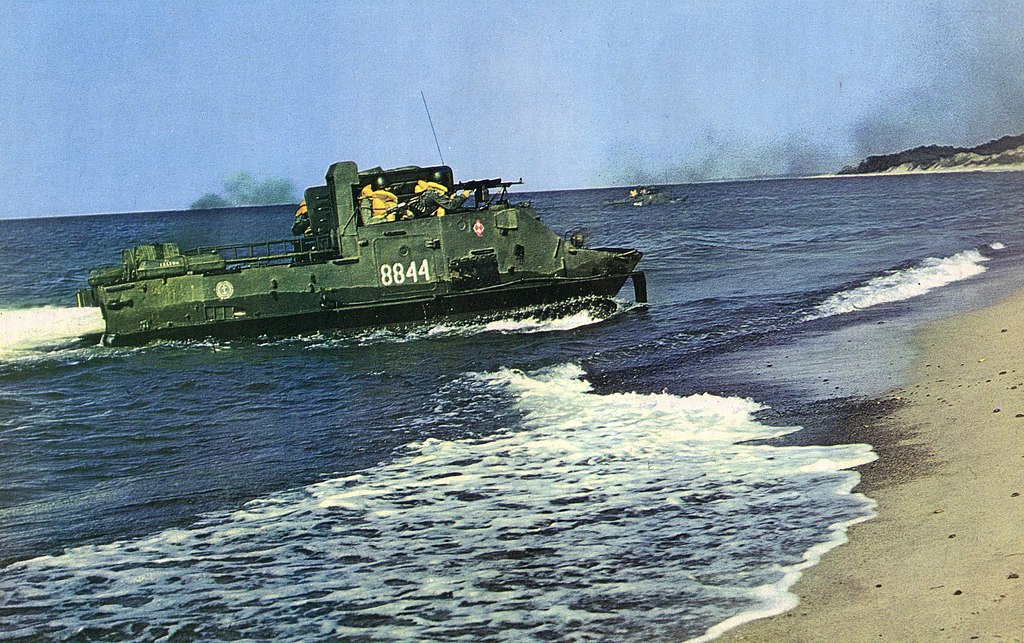

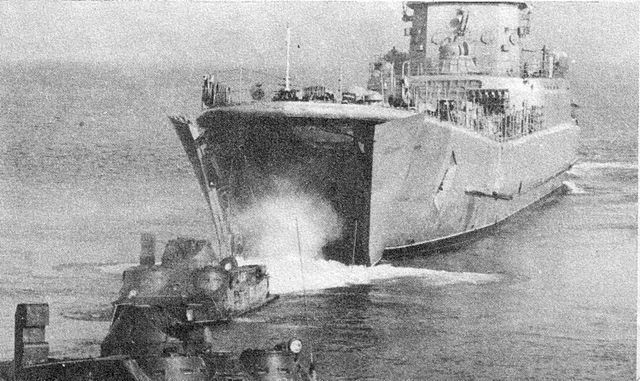

OT-62 TOPAS entered service in the Czechoslovak army by 1963 and the Polish LWP in 1964 working alongside the PT-76 used for fire support. The TOPAS APC and later TOPAS-2AP joined the Polish Coast Defense units, notably the 7th Lusatian Landing Division. Just like in Czechoslovakia, they were replaced in the 1980s and went into depots, then scrapped in the 1990s. The Polish vehicles were possibly deployed during the Prague Spring as their only "combat" use, but it is not corroborated.

The vehicle however saw more action when exported. In the Warsaw Pact, only Bulgaria adopted it. However in Africa-Middle east, customers were not lacking: Angola, Egypt, India, Iran, Iraq, Libya, Morocco, Sudan and Syria adopted the vehicle in its basic form. Egypt and Syria commited both their BTR-50 and OT-62 during the Six-Day War (1967). Many were destroyed and many also captured, later recommissioned by the Israel Defense Forces (IDF). In fact they would see combat on opposite sides again during the War of Attrition (1968–1970) and the Yom Kippur War (1973) but later the IDF decided to transfer its own captured BTR-50 and OT-62 to the South Lebanon Army.

Morocco also used ex-Egyptian OT-62s in its Western Sahara War against the Sahrawi indigenous Polisario Front. 13 were lost after the battle in Lebuirat, 24 August 1979.

Lastly, Iraq also acquired a large contingent during its war with Iran, the latter capturing some, and they saw used agains this time against the coalition forces in the First Persian Gulf War and 2003 Invasion of Iraq. One version fitted with the Cascavel turret was the only infantry fighting variant, while Iran worked on its own IFV as well.

Development

A crappy first APC: The OT-810

After joining the Warsaw Pact in 1955, the Czech republic started to start as alternatives to its mostly fleet of ex-German vehicles plus its own domestic half-track Tatra OT-810 derived from the Sd.Kfz.251. The latter were already partially produced during the war by Škoda Pilsen, Mürzzuschlag-Bohemia, Česká Lípa as well as the SdKfz.250 (Demag D-7) postwar, in reunified Czechoslovakia plus some International Harvester M5 halftracks from Soviet lend-lease supplies.

The new army in 1947 needed new equipment, the supply of American vehicle was over, and the Soviets were reluctant to share anything. Many trophy German vehicles were pressed into service as well as the SdKfz 251 and 250 with the 251 factory redesignated HKL-6 and vehicle production resumed under the name "Hakl", officially OPp3N sent to border guard units, some with the Tatra T-928-3 engine (HKL-6p) from 1952.

Some eengineers were toying with full-lenght tracked APCs such as a possible adapation of WW2 German "Kätzchen" project based on the 38t chassisn but it appeared a bit small, and in 1951, there were still 736 halftracks, most being the HKL-6p and by 1957, 630 (476 HKL-6p) while development of the OT-810 authorized in 1948 by Soviet authorities after local staff preferred it to the all wheeled BTR-152 but real development started in 1952 from the HKL-6p, stopped in 1954, resumed in 1956 with different engine, new body shapes, fully covered infantry compartment, 10 made in 1958-1959, accepted as "Obrněný transportér" in 1959 and some 1,140 were made between 1960 and 1962 in Slovakia.

It was not popular, being heavier than the original, hard to control, with a cramped, hot infantry compartment and a difficult maintenance. It was soo poor as nicknamed by the troops "Hitlerova pomsta" ("Hitler's Revenge"). They joined the warehouses for a long time as soon as an alternative was available.

The need for a modern amphibious APC

In between, after joining the Warsaw Pact, Czech officers were "invited" to standardize and adopt Soviet organization, and this included some vehicles which could only be produced in USSR. One of this was an fully tracked APC, the BTR-50. Before it was replaced years later by the MT-LB or by wheeled equivalents, cheaper, the Czech army staff looked the Soviet vehicle with desperation rather than envy to replace the excecrable OT-810.In the spring of 1956, the Commander of the Tank and Mechanized Troops submitted to the Technical Administration of the General Staff preliminary technical and tactical requirements for a 12 t amphibious APC (something the OT-810 wasn't, neither NBC). Requirements received annotations and recommendations by Soviet military and technical experts by early 1957. Modified technical and tactical requirements were reworked in Czech military academies, went through the Ministry of General Engineering, R&D Centre J. V. Stalin in Martin and two preliminary designs drawn up in Turiec: > TOPAS 1, two engines

> TOPAS 2 one engine.

The latter was selected and completed by the summer of 1958 and consulted by Stalingrad plant team which criticized the excessive complexity and instead pressed to start again on a modernization of the existing Soviet BTR-50PA. This was approved by September 1958 while licensing documentation translated into Czech, was asked for, and soon three BTR-50PA were sent by rail. Deadlines were pushed down by 5 months, but this enable to modernise the Soviet design with critical changes in layout. The original engine was now turbocharged, transmission a new five-speed gearbox with combined directional gear train, new torsion bars, new drive wheel, a new commander's turret, new gunner's turret adapted to mount the Czech vz. 59. Two prototypes emerged from these works by October 1959 and summer 1960, tested locally by the autumn.

So by 1960 Czechoslovakia had two "modernized BTR-50" that could also interest the Soviet Union for future upgrades. The new tracked armoured personnel carrier for the Czechoslovak army was also now aimed as well for Poland, which looked after a similar vehicle (Ludowe Wojsko Polskie or LWP). Adapation work started at the same time in 1958 at Wojskowa Akademia Techniczna (WAT) (Polish Military Technical Academy) and Wojskowy Instytut Techniki Pancernej i Samochodowej, the Military Institute of Armour and Car Technology, and a first prototype completed in 1962. It passed trials and was accepted under the acronym TOPAS. Production started at Podpolianske Strojárne.

Military trials in 1961 meanwhile were divided into static design verifications to match the TTZ, and tactical exercises modelled after the need of the 1st Czech Armoured Division as well as an added set of riverine, lake and sea trials. In the latter the vehicle proved stable, buoyant enough, stable in navigation and not lowered too much even when loaded with the recoiless Czech 85 mm gun vz.52, or even carrying a GAZ-69. On land, the vehicle was used for towing and transporting various ordnances, notably the 82 mm BzK vz. 59, 120 mm mortar vz.42N, or two mortars vz. 52 including ammunition. It went as far as firing the mortars underway. All tests were satisfactory, and went beyonf requirement as usual in Soviet practice.

The OT-TOPAS was greenlighted by the procurement bureau by November 1962 and received the official designation OT-62. Production was setup to start in 1963 and was schedule to run until 1968 at PPS Detva to cover the need of the Czech army, a total of 890 vehicles when the manufacturing ceased. They provided for the sixties and until the eighties, the bulk of Czech motorized artillery regiments associated with Czech tank divisions. The first vehicles started to be replaced by the late 1970s, and many joined depots, replaced by the BMP-2.

The basic Polish People's Army vehicle was unarmed and so Wojskowa Akademia Techniczna (WAT) bureau developed an armed variant, designing a new turret placed which was placed on top of the superstructure, in the middle. The other Polish TOPAS variant from the Military Institute of Armour and Car Technology was the WPT-TOPAS, used for technical support. But the OT-62 was also built in Czechoslovakia.

Design

Like the BTR-50PK, the OT-62/TOPAS uses very same flat and vaguely boat-shaped underbelly hull. The layout is the same also, engine at the rear, superstructure in front of the vehicle. The entire hull is made of all-welded rolled steel, and the crew compartment is at the front, followed by a small troop compartment, center and engine compartment at the rear. The troop compartme it quite cramped and still is roomy enough for two benches runing across the full width, for sixteen men total eight per side.

Access and exit in particular in this type is specific, by climbing over the sides of the hull, going through two rectangular roof hatches but more than the BTR-50, the OT-62/ TOPAS has side hatches on both superstructure sides, less reisky under fire than rectangular roof hatches leaving the troops exposed to enemy fire.

The driver is seated in the center-front of the hull, under a dome shaped forward post, topped with three vision blocks and periscopes above, at the top of the sloping glacis plate. By night the TVN-28 night vision is installed for safe driving, one the center periscope, giving a clear range of 60 meters. The driver could access via a small hatch opening upwards and not too prominent for secured day driving while buttoned up in safe areas. For exit, he probably uses normally the side hatches in the superstructure behind, of has his own emergency hatch anyway below, useful in case of turnover, and available to a all crew members.

The commander is seating on the left side od the structure, and is also given three vision blocks, periscopes in a small projecting bay. He also has a cupola with vision blocks only facing forward. The cupola is also a hatch opening forward, on top of projecting bay, locked vertically to keep it up when underway on bumpy terrain. This is probably the most distinctivepoint about the vehicle compared to the BTR-50: Two side hatches and two projecting bays as on the BTR-50PU, with reshaped bays. The second projecting bay had on top a cupola replacing the additional BTR-50PK rectangular roof hatch.

Protection

The overall protection is ensured against heavy machine gun rounds (14 mm for the sloped glacis nose, as well as the Turret) and down to 7 mm (OT-62B and OT-62C) for the hulls, so prood against light arms fire and shrapnel only. There is no basic NBC protection, no smoke projectors, but apparently still a fire extinguishing system both in the troop and engine compartments. Due to the configuration of the vehicle, amphibious, it's not possible to inject fuel into the exhaust to produce additional smoke.Engine and Performances

The OT-62 is powered by the PV-6 6-cylinder inline diesel engine rated for 300 hp (220 kW) at 1,800 rpm, for a road speed of 60 km/h, cruising range of 450 km to 550 km depending on terrain and load. On trials, the vehicle was seen able to cross 0.9 m high vertical obstacles, gap 2.8 m wide trenches, climb 38° gradients and ford any body of water without preparation but raising in case the trim vane forward.

The drive train is generally similar to the PT-76 light tank. There are six evenly spaced cast/stamped large rubber-tired road wheels on either side, single pin tracks, rear drive sprocket and front idler. Due to the sprocket and transmission being compacted at the rear, this keeps the vehicle's profile low. The road wheels are not only stamped, they are hollow and relatively thin for extra buoyancy, with some studied of the time stating as much as 30% increase. Thius drivetrain does not provides track-return rollers.

The suspension system comprises torsion bar suspensions for all axles, but the first and last roadwheels axles are doubled on hydraulic shock absorbers. The steel single pin tracks are going in between roadwheels (the simplest, cheapest configuration) comprising a thread of 96 chain links each. The vehicle has no skirt per se, but a small and thin, horizontal skirt over each track, which is barely visible.

The amphibious caracteristics are helped first by the buoyancy offered by the wide and flat, boat-shaped hull, completely watertight, shaped for minimal resistance afloat. For fording or swimming, the driver activates the two electric bilge pumps, erect the trim vane as well as switching the periscope to the swimming one, much taller to see above the trim vane underway. In case the crew could activate an internal backup manual bilge pump in emergency. These bilge pumps had been tested and are energy-independent to function even if the vehicle was hit and engine cut. Propulions is ensured by two hydrojets, either side of the hull.

There are also additional assistant water-jet entrances on either sides and over the last road wheels. This is bsically the same system as on the BTR-50 and PT-76. For extra agility, rear waterflow exits receives rubber lids, fully or partially closed to redirect the water stream into the forward-directed side exits thus enabling the vehicle to turn on itself when swimming or go in reverse. Both right and left water-jets can either suck or push out for extra agility, as designed by N. Konowalov. The only issue with the design is to tackle any rough seas. It had a low freeboard of 15-20 cm, but compensating by using a tailored snorkel mount located on the right side of the front of the engine deck.

In addition to its night vision sights, the TOPAS is also given an IR driving light close to standard lights forward on the nose, and an IR searchlight located on the left side, but it can be swapped. On the BTR-50 it was on the right side, superstructure front but moved on the OT-62 close to the commander's cupola. Each side are giveen hooks and attachement points for shovels on either side, front, pickaxes on the superstructure and there is also a stowage bucket centrally in the front of the engine deck.

Armament

Polish TOPAS 2AP and its KPVT armed turret.

The basic APC was unarmed, except for the infantry aboard personal weapons, mortars, ATGMs and MANPADS. However this was seen as lacking the Poland notably pressed for the adoption of a turret. On the Czech size was developed the OT-62B, caracterized by a small rotating turret placed on top of the second projecting bay (replacing the cupola). It was fitted with a mount for the 7.62 mm Vz. 59T general purpose machine gun. More, a cradle like system was installed alongside to fire also the 82 mm T-21 "Tarasnice" recoilless gun. This was an external, one shot mount and needed a sortie to reload it, exposing the one doing it to enemy fire...

Before the age of internally aimed automatic ATGMs, this was a solution. 5-10 rounds were carried for the 82 mm T-21 "Tarasnice". The Czech antitank capabilities were translated into Poland by Ludowe Wojsko Polskie as the TOPAS-2A. The T-21 fires 82 mm grenades with high-explosive fragmentation (HE-F) warheads. The gun had a day sight with fixed 1.48x magnification, 1,800 metres range and at best, 10rpm in this configuration, although it could have been fitted with 6-round magazines. Traverse was very limited here, but it had a -5 +22.5° elevation.

But the most heavily armed without doubt was the OT-62D, which keeps the armament of the OT-62B but with a 82 mm Bzk vzor 59 recoilless gun installed complete (with its wheeled undercarriage) on the rear deck, to be easily dismounted or fired direbtly on the move. The latter is even more intended as anti-tank support. The vz.59 had a much longer barrel and muzzle velocity (50 m free behind !), 12.7mm ZH 59 spotting rifle for great accuracy and its HE shell however can still defeat 250 mm RHA. For artillery, range is 6,000m.

The Polish variant TOPAS 2AP came into two "favours" and are equally well armed. The basic version is the heaviest, being modified with a central one-man WAT turret sporting a 14.5 mm KPVT heavy machine gun, mounted coaxially with a 7.62 mm SGMT coaxial medium machine gun. Same turret as on the SKOT-2AP. The 7.62 mm SGMT was later replaced by the more modern Soviet 7.62 mm PKT general purpose machine gun. The top rectangular roof hatches could not be kept due to the turret ring and were moved to the sides-top of the superstructure. With three crew members, bulk of the turret basket and associated ammunition, the rear compartment lost four seats, from sixteen to twelve. With 16 tonnes fully loaded, the vehicle still should have enough buoyancy to perform on water.

The second "flavour" is even more radical as the rear compartment is gutted and infantry replaced two 82 mm mortars served by 8 mortar crew members. The 82 mm mortar has a rate of fire of 25 rounds per minute and 50-100 mortar rounds are carried. This made the vehicle (unofficially TOPAS 2APM) no longer an APC but a support vehicle, although without antitank capabilities. It should be noted that the latter was provided by the TOPAS 2A.

Armed Specialized Variants

Polish TOPAS WPT salvage vehicle, differing from the Czech DTP-62.

Poland also used a similar signals/command vehicle but was the only one to develop a completed salvage vehicle, more advanced than the Czech DTP-62 but not adopted by Czechoslovakia. This Polish version is called Wóz Pogotowia Technicznego, abbreviated as WTP for "Technical Support Vehicle". It is tailor to salvage other TOPAS and PT-76 light tanks left damaged on the battlefield, and those bogged down or trapped when their amphibious ability fails. The intention was to retreive them thanks to a set of powerful winches, two them to the rear for field repairs, including medical help for potential wounded crew members in the troop compartment. It is equipped with the following:

-Main winch, maximum capacity 2.5 tonnes, 600 m cable

-Manual crane, maximum capacity 1 tonne but movable to be fixed around the vehicle

-Stowage boxes with tools, devices and field repair equipments

-Welding set, pontoon, divers equipments.

-Single PK general purpose machine gun (right side cupola, v-shaped shield).

OT-62 APC specifications | |

| Dimensions | 7.1 x 3,14 x 2,1 m |

| Total weight, battle ready | 13/15 tonnes FL |

| Crew | 2 (driver and commander) +16 passengers |

| Propulsion | PV-6 6-cylinder, in line diesel 300 hp (220 kW) at 1,800 rpm |

| Suspension | Torsion bar, ground clearance 410 mm |

| Speed (road) | 60 km/h (road), 10,8 km/h (water) |

| Range | 407 liter tank, 450–550 km (road), 150 km (water) |

| Armament | None, see note and variants |

| Armor | Welded, rolled steel 17 mm thick |

| Total production | c5000 estimated |

Variants

Czech Variants

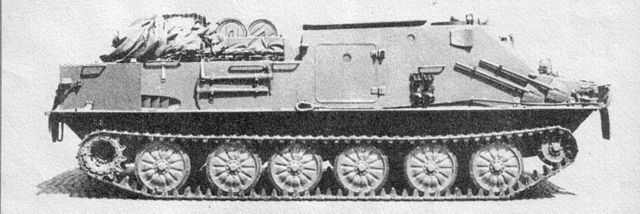

TOPAS WPT

OT62

Basically a BTR-50PK copy with hull side hatches, 300 hp PV-6 engine, two projecting bays as for the BTR-50PU.OT-62A

Main production variant (Czech). 16 infantry seated back, 2 crew.OT-62B

Small turret with 7.62 mm Vz. 59T, 82 mm T-21 recoilless gun. Same capacity.OT-62 R-2 R-105

Signals/command vehicle with R-113, R-112, R-105U and R-105d radios, MG turret, not recoilless gun, stowage box on the left side of the engine deck.OT-62 R-2 R-108

Same but with a generator and stowage box, left side of the engine deck.OT-62 R-2M

Same but improved radios. Model also used by poland as TOPAS R-2M.OT-62D

OT-62 with 82 mm Bzk vz59 recoilless gun on rear deck and same as OT62B.OT-62A

Not the same as the main production version, this one is an armoured ambulanceDTP-62

OT-62A Technical support vehicleOT-62 R-3MT

Dedicated signals and command vehicle, additional radios, generator, two stowage boxes (engine deck), collapsible radio mast, dome shaped ventilators, top left cupola moved to the center.OT-62 R-4MT

Same as above but right side hatch removed.Polish Variants

TOPAS

Basic APC, unarmed, equivalent to the OT-62 and 62A. 16 infantry seated back, 2 crew.TOPAS-2A

Same as OT-62B, armament in a turret and recoiless rifle.TOPAS-2AP

New armament: Central one-man WAT turret, 14.5 mm KPVT/7.62 mm SGMT(later PKT). Roof hatches moved sides/top superstructure. Infantry down to 12. Weight 15.1 to 16t FL.TOPAS-2APM

Sub-variant with 2x 82 mm mortars, 8 mortar crew.WPT-TOPAS

Technical Support Vehicle variant intended to evacuate damaged TOPAS APCs/PT-76 from the battlefield.TOPAS R-2M

Signals and command vehicle with additional radios, similar to the OT-62 R-2M.TOPAS R-3M

Signals and command vehicle with additional radios, presumably close to R-3MTIndian variant

India acquired an unknown number of Polish TOPAS, TOPAS-2A and FRT TOPAS in the 1980s. On this base was developed a domestic variant, the FRT TOPAS ("Forward Repair Team vehicle"), TOPAS-2A based technical support vehicle.Iraqi variant

Iraq acquired perhaps 100 vehicles, first-hand from Czechoslovakia in the early 1980s. Its only "quirky" variant, postwar, was the local "OT-62A" fitted with the Brazilian EE-9 Cascavel armoured car turret, also adopted by Iraq. The new combo was intended for fire support and impressive on paper, however apart photos showing the same we have nothing to go from. It could be assumed that it was a single prototype that did not went further, for obvious reasons: The weight of the turret was probably beyond what the chassis can support, unlike the latter MT-LB that was designed for this future additions.Israeli variant

OT-62 in Latrun

IDF captured an estimated 80-120 Syrian and mostly Egyptian Czech-built OT-62s in 1967. Under the name OT-62A the upgrade was limited to fitting two israeli designed machine gun mounts, each in front of a hatch on top of both cupolas, for the Browning M1919A4. This was a quick and cost-efficient standardization. IDF vehicles were withdrawn from service in 2002, at least one surviving in a museum.

In action

OT-62 TOPAS entered service in the Czechoslovak army by 1963 and the Polish LWP in 1964 working alongside the PT-76 used for fire support. The TOPAS APC and later TOPAS-2AP joined the Polish Coast Defense units, notably the 7th Lusatian Landing Division. Just like in Czechoslovakia, they were replaced in the 1980s and went into depots, then scrapped in the 1990s. The Polish vehicles were possibly deployed during the Prague Spring as their only "combat" use, but it is not corroborated.

The vehicle however saw more action when exported. In the Warsaw Pact, only Bulgaria adopted it. However in Africa-Middle east, customers were not lacking: Angola, Egypt, India, Iran, Iraq, Libya, Morocco, Sudan and Syria adopted the vehicle in its basic form. Egypt and Syria commited both their BTR-50 and OT-62 during the Six-Day War (1967). Many were destroyed and many also captured, later recommissioned by the Israel Defense Forces (IDF). In fact they would see combat on opposite sides again during the War of Attrition (1968–1970) and the Yom Kippur War (1973) but later the IDF decided to transfer its own captured BTR-50 and OT-62 to the South Lebanon Army.

Morocco also used ex-Egyptian OT-62s in its Western Sahara War against the Sahrawi indigenous Polisario Front. 13 were lost after the battle in Lebuirat, 24 August 1979.

Lastly, Iraq also acquired a large contingent during its war with Iran, the latter capturing some, and they saw used agains this time against the coalition forces in the First Persian Gulf War and 2003 Invasion of Iraq. One version fitted with the Cascavel turret was the only infantry fighting variant, while Iran worked on its own IFV as well.

fate

By the end of 1990, Czech and Slovakian storage facilities at Sternberg and Presov started to gradually sold them for scrap. After 1993, some were to be refurbished to join the new Slovak Republic army. But the Treaty on Conventional Armed Forces in Europe resumed their scrapping until 1994, the year the last were dismantled, with a few remaining in various museums.Gallery

Czech OT-62 R2M

Czech OT-62D

Polish TOPAS basic APC

Polish TOPAS 2AP

Egyptian OT-62

Egyptian OT-62

Egyptian OT-62B

Captured Egyptian OT-62

IDF OT-62

IDF OT-62, Syrian front 1970s

Iraqi OT-62, Iran-Iraq war

Iraqi OT-62 captured Op. Daguet 1991

IRAQI OT-62 with Cascavel turret

Ex-Iraqi Iranian OT-62

Egyptian/ukrainian upgrade kit for OT-62 Topas as IFV : UTD-20 engine, R2 Skif ATGM, 30mm ZTM-1 cannon, AGS-17 grenade launcher

More photos

OT-62 RT3MT Zelva

Czech OT-62B

TOPAS 2AP

TOPAS TBiU

TOPAS 7 TOW

TOPAS

Sources

globalsecurity.orgarmy-guide.com

mortarinvestments.eu

en.wikipedia.org

weaponsystems.net

how-not-to-make-apc-cz-ot-810-and-ot-90

armedconflicts.com

army-guide.com

armyrecognition.com

armyrecognition.com

elpais.com

scalemates.com

Videos

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com