The AHS (armatohaubica samobieżna) Krab ("crab") is a 2008, 155 mm self-propelled, tracked, gun-howitzer from Huta Stalowa Wola (HSW). It combined initially a modified South Korean K9 Thunder chassis, with a British AS-90M Braveheart turret, with a new 52-calibre gun from HSW. Polish WB Electronics provided the Topaz artillery fire control system. In 2011 a prototype tested the Nexter Systems barrels and UPG-NG chassis from Bumar-Łabędy. From 2016 it was produced on a modified K9 chassis with an STX Engine-MTU Friedrichshafen engine and from 2019 a new HSW barrel instead of Rheinmetall.

The new Polish cannon was developed from 1996 through a local program called "Regina". This 155 mm calibre was designed as a long-range (L52 is possible) artillery piece to be deployed at division-level. One of the program's goal was to produced as much as possible at home. So instead of licencing for a complete vehicle, a licence was acquired for the L/52 gun-turret alone, in order to mount it on a domestically developed chassis.

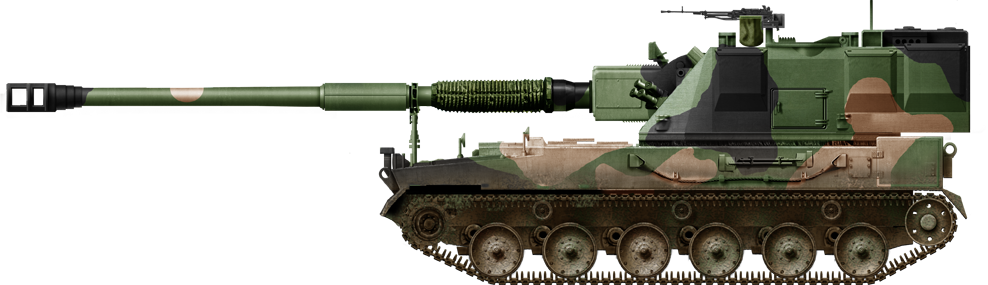

The initial pre-production AHS Krab exhibited in 2008.

In 1997, an international competition for a complete turret with gun was announced. The shortlist ended with BAE System (AS-90M) and KMW (PzH-2000) and the first won. In 1999, the BAE turret technology was transferred to Huta Stalowa Wola factory that was responsible for the integration on an UPG-NG chassis developed in Poland by OBRUM (Gliwice). It was derived from an SPG-1M chassis, which itself derived in turn from a Soviet MT-S tractor, combined with parts frop the domestic PT-91 Twardy. First prototype was ready for test by 2001, a second in 2002.

The first two had the turret systems directly supplied by BAE Systems and a first squadron already planned to be equipped in 2008, but budgetary constrains delayed the program by 2008, for a first pre-production squadron batch in 2012. In total were eight vehicles completed, six pre-production etst vehicles and two upgraded prototype. They were associated as a unit with a command vehicle designed on a modernized Polish MTLB chassis, to what were added ammunition and repair vehicles.

As work progressed on a larger serie, Nexter guns proposed a replacement of the original British orndnance, with regular trial until the end of 2008. The third gun was tested on 10 August, attended by the Armament Inspectorate, and Head Office of the Missile and AF Artillery branch at the Dynamic Trial Center (WITU), Military Technical Institute of Armament at Stalowa Wola.

The first firing test of a third pre-production, complete Krab with the new Nexter gun and new onboard systems from WB Electronics, performed by July 2011. The choice of a Nexter gun was due to the manufacture of L31A1 barrels being terminated. In 2012, the two prototypes and eight initial units as well as the two artillery batteries (four Krab each) were delivered by Huta Stalowa Wola for field evaluation and in 2012–2013 eight new vehicles entered a new test cycle as a part of a "Regina" battery command module, completing the program as intended (1996-2013).

In December 2014, the Polish MoD announced a US$320M contract with Samsung Techwin (Hanwha Techwin today) for a production chassis, no less than 120 K9 Thunder chassis. The schedule planned 24 to be delivered in 2017, 96 built under licence in Poland between 2018 and 2022. Since the Turkish Firtina T-155 used the same chassis, one ws purchased for evaluation. The reason of this swap was that the BUMAR UPG-NG chassis used for the first eight pre-production vehicles was no largely obsolete and problematic. It was powered by the S-12U engine and road wheels from the PT-91. Structural cracks were observed while the production of the S-12U engine was terminated.

The first K9 chassis arrived in Poland for testing and integration by June 2015. The mating was done in July and the prototype ready by August. It went through acceptance trials by October, and the cycle was completed with flying colors by April 2016. This greenlight production. It was time, as since the 2014 war in Donbass, there were serious concerns over these long-term program and the need to complete these. To accelerate things later, K9 Thunder SPHs were purchased as complement. In April 2016 the research and development phase was announced complete (1996-2016 so 30 years...). In April 2016 the Polish MoD visited Stalowa Wola to comment on the first production Krab handed over to the Polish Army.

They were sent for testings at the Artillery Training Center in Toruń, defining operational standards. The transfer ceremony was helf on November 2016, with nine Krabs accepted in the presence of the Polish Minister of National Defence (MND), and seven more in acceptance testing. Eight original turrets were extracted from the now discarded UPG chassis, to be adapted to the K9 chassis after 16 delivered by late 2016. A deal for 96 more was signed in December 2016, whereas 120 Krabs were planned to fill five regiments. It was planned to import 36 chassis from South Korea, produce 84 in Poland to reach this 120 vehicles FY2022 but it slipped to 2024 as domestic produced increased to 96.

The pre-production Krab with the initial UPG chassis

The engine is at his right and its air inlet and louvres ar located on top with an exhaust outlet also to the right side and blowing downwards to better conceal the vehicle at night. The diesel fuel tanks are located under the floor. The turret was the chosen initial AS 90 BAE model and its configuration is identical to the original, thus, it is made of welded RHA, 17 mm thick on the front glacis, NATO-proven against small arms fire, 14.5 mm armor piercing shells and 152 mm shell fragments. It has sloped sides, and measured anbout 2/3 of the whole hull for an overall length around nine meters. In it, the commander, gunner and loaders were housed inside the turret, with a rear door for access/exit and ammunition supply. The command and gunners have access to day/night sights with magnification.

Early production Krab howitzers used a highy modified chassis of the Polish PT-91 Twardy man battle tank and thus were given S-12U diesel engine rated for 850 horsepower for a still honorable top speed of 60 km/h. The chassis as completed powered a self-entrenching blade to prepare defensive emplacements. Suspension comprised torsion bar on seven dual rubber-tyred road wheels (same as the Twardy) drive sprocket at the front, idler at the rear plus three track return rollers. The upper suspension is covered by a skirt for protection against mud and RPGs.

From 2012, production of the S-12U engine powering the PT-91 nd Krab stopped. So the company behind the program opted for a German MTU-881 Ka500 engine as an alternative. It was more powerful, but did not fit in the slender compartment without substantial modifications. So much so that with delays slipping and costs rising it was decided instead to test in 2013 the Turkish T-155 Firtina. Since it used a modified K9 Thunder chassis, in 2014, 120 of these chassis were ordered, with the first Polish made chassis completed and tested in 2015.

The K9 chassis is lower, but still keeps the same original configuration with six roadwheels, instead of seven, otherwise, the same front drive sprocket and rear idlers, and three return rollers. The axles are suspended by torsion bars. The powerplant is now an STX Engine/MTU Friedrichshafen MT881Ka-500 engine rated for 1,000 hp @2,700 rpm, so far more than the former engine, resulting in better performances across the board, notably as it is coupled with a SNT Dynamics/Allison Transmission X1100-5A3 (4+2 speeds) for a top speed on flat of 67 km/h (42 mph) and a max range of 360 km (220 mi) based on 850 L (225 U.S. gal).

The turret of the Krab remained almost identical to the one on the AS90 Braveheart, but license-produced in Poland and fitted initially with the BAE L31A1 155 mm/L52 howitzer compatible with all standard NATO 155 mm ammunition. In addition the Krab has an automatic shell loading system, albeit part of the process is still managed by a loader. It also has a modular charge system. Maximum range started at 30 km with standard ammunitions, HE-FRAG shell. It was extended to 40 km with rocket assisted shell and 60 shells are carried. Later precision-guided munitions were also tested and adopted. However the end of production of the L31A1 meant a Nexter equivalent was adopted, albeit the loading system in 2012 was not findamentally altered, nor the ammunition capacity.

The secondary armament is defensive, consisting of a roof-mounted Polish 12.7 mm machine gun on left side of the turret roof. It could both mount an NSV or a Browning M2HB. To go with the ordnance the Krab ois fitted with the domestic Topaz fire control system as well as local intercom and radios, which imposed the bulk of turret internal changes. In addition there is also a Danish muzzle reference system automatically adjusting the next shot from the trajectory of the previous shot.

According to HSW, the Krab has is capable of three rounds in 10 seconds and a cyclic rate of 18 rounds in three minutes or six rpm. The flick rammer notably helps in this and avoid mishaps and accidents of manual loading. Minimum range is 4.7 km, maximum range (with assisted projectile) 40 km as said above. Accuracy is on a 0.5% ratio on the distance, with an azimuth or 0.1%. The gun commander uses its DD-9620 terminal with target information from the battery command post (another dedicates vehicle) whereas a muzzle velocity measuring radar feeds local information on top of this previous data, to the fire-control system. There is also a GPS type navigation system.

The general control computer for the turret is completed by the gun layer computer and ballistic calculation/gun command computer. In case of a closer engagement, thers is a direct fire sight and laser range-finder, coaxial with the main gun. It authorized to fire special AT ammunitions, such as the German SMArt 155 (A carrier shell with two anti-armour and anti-artillery submunitions), Israeli dual purpose DPICM and M454 (IMI) HE Frag, and Swedish-French 155 BONUS which is a sensor fused submunition-carrying anti-tank projectile with two anti-armour submunitions (Max range 35 km).

In case the Krab is static, engine cold, there is an APU for the turret allowing to power all Krab combat systems. The front-mounted dozer blade remained an option on the new chassis.

2024 saw the delivery of all vehicles but a remaining 42 vehicles was postponed until 2027. Current value is 3.8 billion zlotys (USD $797 million) for the 48 vehicles expected until 2027. The total contract amounted to 152 Krab as signed by 8 December 2023 at PLN 10 billion (approx. $2.49 billion). Not only this includes 96 Krabs, but associated per-unit basis command vehicles, command and staff vehicles as well as ammunition vehicles, and repair workshops. This final contract was signed on 23 December 2024 with a final delivery planned FY2029.

By late May 2022 18 Krabs were donated to Ukraine. Later was signed a contract, under which Poland sold Ukraine an additional 60 Krabs at 3 billion złotys (US$700 million), paid notably the US. Thus, Ukraine officially became the first export customer for Polish Krab and this became the largest defence contract Poland made in 20 years. By October 2022, Ukraine's MoD Oleksii Reznikov revealed three battalions (54 with support vehicles) were already transfered and crews training for deployment, with three more ordered, 108 acquired by August 2024. OSINT so far stated 30 had been destroyed, 6 damaged at the time. As of February 2025, the total is still 36 lost.

From the 2022 Russian invasion of Ukraine and donation of Krabs, ukrainian soldiers compared it very favourably compared to the primitive legacy 2S19 Msta-S 152 mm. They reported it much easier to operate with much greater accuracy and longer range as well as better mobility. For accuracy it is reported that most shells land within 50 meters of thier target at max range. However, even no NATO vehicle designed pre-2022 is immune to drones, which imposed extra measures. It is also slower to operate from underway to firing and underway modes than wheeled SPH such as the Casear and Archer.

Development

In the mid-1990s the Polish Army aimed at modernizing its soviet-era legacy park, and gradually replace all systems if possible with NATO-compatible vehicles. The artillery range mostly comprised the 2S1 Gvoździk (tracked) and Wz. 1977 DANA (wheeled), and it was planned to replace both for the 2030. The tracked vehicle had prioritty notably to be compatible with NATO standard 155 mm (6.10 inches) caliber. The second plan the partial replacement of the Dana (which could be equipped with a NATO gun) with a new wheeled vehicle based on the local KTO Rosomak, the M-120 Rak SP mortar.The new Polish cannon was developed from 1996 through a local program called "Regina". This 155 mm calibre was designed as a long-range (L52 is possible) artillery piece to be deployed at division-level. One of the program's goal was to produced as much as possible at home. So instead of licencing for a complete vehicle, a licence was acquired for the L/52 gun-turret alone, in order to mount it on a domestically developed chassis.

The initial pre-production AHS Krab exhibited in 2008.

In 1997, an international competition for a complete turret with gun was announced. The shortlist ended with BAE System (AS-90M) and KMW (PzH-2000) and the first won. In 1999, the BAE turret technology was transferred to Huta Stalowa Wola factory that was responsible for the integration on an UPG-NG chassis developed in Poland by OBRUM (Gliwice). It was derived from an SPG-1M chassis, which itself derived in turn from a Soviet MT-S tractor, combined with parts frop the domestic PT-91 Twardy. First prototype was ready for test by 2001, a second in 2002.

The first two had the turret systems directly supplied by BAE Systems and a first squadron already planned to be equipped in 2008, but budgetary constrains delayed the program by 2008, for a first pre-production squadron batch in 2012. In total were eight vehicles completed, six pre-production etst vehicles and two upgraded prototype. They were associated as a unit with a command vehicle designed on a modernized Polish MTLB chassis, to what were added ammunition and repair vehicles.

As work progressed on a larger serie, Nexter guns proposed a replacement of the original British orndnance, with regular trial until the end of 2008. The third gun was tested on 10 August, attended by the Armament Inspectorate, and Head Office of the Missile and AF Artillery branch at the Dynamic Trial Center (WITU), Military Technical Institute of Armament at Stalowa Wola.

The first firing test of a third pre-production, complete Krab with the new Nexter gun and new onboard systems from WB Electronics, performed by July 2011. The choice of a Nexter gun was due to the manufacture of L31A1 barrels being terminated. In 2012, the two prototypes and eight initial units as well as the two artillery batteries (four Krab each) were delivered by Huta Stalowa Wola for field evaluation and in 2012–2013 eight new vehicles entered a new test cycle as a part of a "Regina" battery command module, completing the program as intended (1996-2013).

In December 2014, the Polish MoD announced a US$320M contract with Samsung Techwin (Hanwha Techwin today) for a production chassis, no less than 120 K9 Thunder chassis. The schedule planned 24 to be delivered in 2017, 96 built under licence in Poland between 2018 and 2022. Since the Turkish Firtina T-155 used the same chassis, one ws purchased for evaluation. The reason of this swap was that the BUMAR UPG-NG chassis used for the first eight pre-production vehicles was no largely obsolete and problematic. It was powered by the S-12U engine and road wheels from the PT-91. Structural cracks were observed while the production of the S-12U engine was terminated.

The first K9 chassis arrived in Poland for testing and integration by June 2015. The mating was done in July and the prototype ready by August. It went through acceptance trials by October, and the cycle was completed with flying colors by April 2016. This greenlight production. It was time, as since the 2014 war in Donbass, there were serious concerns over these long-term program and the need to complete these. To accelerate things later, K9 Thunder SPHs were purchased as complement. In April 2016 the research and development phase was announced complete (1996-2016 so 30 years...). In April 2016 the Polish MoD visited Stalowa Wola to comment on the first production Krab handed over to the Polish Army.

They were sent for testings at the Artillery Training Center in Toruń, defining operational standards. The transfer ceremony was helf on November 2016, with nine Krabs accepted in the presence of the Polish Minister of National Defence (MND), and seven more in acceptance testing. Eight original turrets were extracted from the now discarded UPG chassis, to be adapted to the K9 chassis after 16 delivered by late 2016. A deal for 96 more was signed in December 2016, whereas 120 Krabs were planned to fill five regiments. It was planned to import 36 chassis from South Korea, produce 84 in Poland to reach this 120 vehicles FY2022 but it slipped to 2024 as domestic produced increased to 96.

Design

The pre-production Krab with the initial UPG chassis

Layout

The chassis of the Krab self-propelled howitzer was inisially a new domestic design using proven parts from previous chassis. It was made of all-welded steel construction but only protects from small arms fire and shell splinters. The driver is seated at the front-left with a single-piece hatch cover and when buttoned-up, observes the surroundings though a single wide-angle day periscope that can be swapped by a passive periscope for night driving. It is mounted on the forward part of the hull. The driver is also responsible of setting up the gun travel lock for the ordnance, from within the vehicle.The engine is at his right and its air inlet and louvres ar located on top with an exhaust outlet also to the right side and blowing downwards to better conceal the vehicle at night. The diesel fuel tanks are located under the floor. The turret was the chosen initial AS 90 BAE model and its configuration is identical to the original, thus, it is made of welded RHA, 17 mm thick on the front glacis, NATO-proven against small arms fire, 14.5 mm armor piercing shells and 152 mm shell fragments. It has sloped sides, and measured anbout 2/3 of the whole hull for an overall length around nine meters. In it, the commander, gunner and loaders were housed inside the turret, with a rear door for access/exit and ammunition supply. The command and gunners have access to day/night sights with magnification.

Mobility

Early production Krab howitzers used a highy modified chassis of the Polish PT-91 Twardy man battle tank and thus were given S-12U diesel engine rated for 850 horsepower for a still honorable top speed of 60 km/h. The chassis as completed powered a self-entrenching blade to prepare defensive emplacements. Suspension comprised torsion bar on seven dual rubber-tyred road wheels (same as the Twardy) drive sprocket at the front, idler at the rear plus three track return rollers. The upper suspension is covered by a skirt for protection against mud and RPGs.

From 2012, production of the S-12U engine powering the PT-91 nd Krab stopped. So the company behind the program opted for a German MTU-881 Ka500 engine as an alternative. It was more powerful, but did not fit in the slender compartment without substantial modifications. So much so that with delays slipping and costs rising it was decided instead to test in 2013 the Turkish T-155 Firtina. Since it used a modified K9 Thunder chassis, in 2014, 120 of these chassis were ordered, with the first Polish made chassis completed and tested in 2015.

The K9 chassis is lower, but still keeps the same original configuration with six roadwheels, instead of seven, otherwise, the same front drive sprocket and rear idlers, and three return rollers. The axles are suspended by torsion bars. The powerplant is now an STX Engine/MTU Friedrichshafen MT881Ka-500 engine rated for 1,000 hp @2,700 rpm, so far more than the former engine, resulting in better performances across the board, notably as it is coupled with a SNT Dynamics/Allison Transmission X1100-5A3 (4+2 speeds) for a top speed on flat of 67 km/h (42 mph) and a max range of 360 km (220 mi) based on 850 L (225 U.S. gal).

Protection

The Hull and turret all-welded steel construction. It is optimized against small arms fire and artillery shell splinters, there is also a collective NBC protection as well as automatic Halon fire suppression systems in the engine, driver, and main combat compartment. Like the original AS 90 Braveheart, the turrets brings a set of eight forward firing, multiple angles 81 mm electrically-operated smoke dischargers for active concealment, coupled with a laser warning system. Unlike an MBT, the Krab however lacks active detection and supression systems, notably hard kill systems. It is not a frontline vehicles. However as shown by losses in Ukraine, it is stll highly vulnerable to drones and counter-battery fire as being relatively slow to setup, fire and move again. Ukrainian Krabs shows almost systematic anti-drone protection cages in addition to improvized close range jammers.Armament

The turret of the Krab remained almost identical to the one on the AS90 Braveheart, but license-produced in Poland and fitted initially with the BAE L31A1 155 mm/L52 howitzer compatible with all standard NATO 155 mm ammunition. In addition the Krab has an automatic shell loading system, albeit part of the process is still managed by a loader. It also has a modular charge system. Maximum range started at 30 km with standard ammunitions, HE-FRAG shell. It was extended to 40 km with rocket assisted shell and 60 shells are carried. Later precision-guided munitions were also tested and adopted. However the end of production of the L31A1 meant a Nexter equivalent was adopted, albeit the loading system in 2012 was not findamentally altered, nor the ammunition capacity.

The secondary armament is defensive, consisting of a roof-mounted Polish 12.7 mm machine gun on left side of the turret roof. It could both mount an NSV or a Browning M2HB. To go with the ordnance the Krab ois fitted with the domestic Topaz fire control system as well as local intercom and radios, which imposed the bulk of turret internal changes. In addition there is also a Danish muzzle reference system automatically adjusting the next shot from the trajectory of the previous shot.

According to HSW, the Krab has is capable of three rounds in 10 seconds and a cyclic rate of 18 rounds in three minutes or six rpm. The flick rammer notably helps in this and avoid mishaps and accidents of manual loading. Minimum range is 4.7 km, maximum range (with assisted projectile) 40 km as said above. Accuracy is on a 0.5% ratio on the distance, with an azimuth or 0.1%. The gun commander uses its DD-9620 terminal with target information from the battery command post (another dedicates vehicle) whereas a muzzle velocity measuring radar feeds local information on top of this previous data, to the fire-control system. There is also a GPS type navigation system.

The general control computer for the turret is completed by the gun layer computer and ballistic calculation/gun command computer. In case of a closer engagement, thers is a direct fire sight and laser range-finder, coaxial with the main gun. It authorized to fire special AT ammunitions, such as the German SMArt 155 (A carrier shell with two anti-armour and anti-artillery submunitions), Israeli dual purpose DPICM and M454 (IMI) HE Frag, and Swedish-French 155 BONUS which is a sensor fused submunition-carrying anti-tank projectile with two anti-armour submunitions (Max range 35 km).

In case the Krab is static, engine cold, there is an APU for the turret allowing to power all Krab combat systems. The front-mounted dozer blade remained an option on the new chassis.

Users & Operation

Polish Krab

Each regiments of Krabs comprised 24 howitzers. A typical battery consists of 6 Krab and 2 ammunition resupply vehicles (based on Star 1466 6x6 trucks) as well as a single Waran maintenance vehicle and Azalia artillery command and control vehicle. The first unit equipped in 2017 was the 11th Masurian Artillery Regiment, in Węgorzewo. In parallel great strides were made to complete a program of smart 155 mm ammunitions also FY2017. Poland planned 186 to be delivered with a framework agreement for 56 and by February 2022, 78 were delivered. In September 24 were left after donating 54 to Ukraine (see later).2024 saw the delivery of all vehicles but a remaining 42 vehicles was postponed until 2027. Current value is 3.8 billion zlotys (USD $797 million) for the 48 vehicles expected until 2027. The total contract amounted to 152 Krab as signed by 8 December 2023 at PLN 10 billion (approx. $2.49 billion). Not only this includes 96 Krabs, but associated per-unit basis command vehicles, command and staff vehicles as well as ammunition vehicles, and repair workshops. This final contract was signed on 23 December 2024 with a final delivery planned FY2029.

Ukrainian Krab

By late May 2022 18 Krabs were donated to Ukraine. Later was signed a contract, under which Poland sold Ukraine an additional 60 Krabs at 3 billion złotys (US$700 million), paid notably the US. Thus, Ukraine officially became the first export customer for Polish Krab and this became the largest defence contract Poland made in 20 years. By October 2022, Ukraine's MoD Oleksii Reznikov revealed three battalions (54 with support vehicles) were already transfered and crews training for deployment, with three more ordered, 108 acquired by August 2024. OSINT so far stated 30 had been destroyed, 6 damaged at the time. As of February 2025, the total is still 36 lost.

From the 2022 Russian invasion of Ukraine and donation of Krabs, ukrainian soldiers compared it very favourably compared to the primitive legacy 2S19 Msta-S 152 mm. They reported it much easier to operate with much greater accuracy and longer range as well as better mobility. For accuracy it is reported that most shells land within 50 meters of thier target at max range. However, even no NATO vehicle designed pre-2022 is immune to drones, which imposed extra measures. It is also slower to operate from underway to firing and underway modes than wheeled SPH such as the Casear and Archer.

AHS Krab specifications | |

| Dimensions (l-w-h): | 12.1/8.06 x 3.63 x 3 m (39 ft 8 in x 11 ft 11 in x 9 ft 10 in) |

| Total weight: | 48 t (47 long tons; 53 short tons) |

| Crew: | 5: Driver, Cdr, Gunner, 2 Loaders |

| Propulsion: | STX Engine/MTU MT881Ka-500 8-cyl. WL diesel 750 kW (1,000 hp), GBx X1100-5A3 4x2 |

| Suspensions: | Mottrol/Horstman Hydropneumatic Suspension Unit (HSU) |

| Top Speed: | 60 kph (37 mph) on road, 30 kph off-road |

| Range (road)/Fuel: | 400 km (250 mi) |

| Armament (see notes): | Caliber 155 mm (6.1 in), 40 rds, WKM-B .50 BMG |

| Total Production: | Current, 200+ |

Gallery

Sources

militaryfactory.com/armedconflicts.com/

militarytoday.com

army-guide.com

nowastrategia.org.pl

en.defence-ua.com

technology.org

pl.wikipedia.org

BONUS 155mm ammunitions

en.defence-ua.com

bulgarianmilitary.com

On scalemates.com

Modern Tanks

Modern MBTs posters

Denel Bagder (2018)

Type 16 MCV (2016)

Gepard 1A2 last rounds 2011

SANDF

Russian AFVs

Main Battle Tanks