The first US ARV

In a general way, the ARV (Armoured Recovery Vehicle), a military acronym well known today as AVLB (bridge layer) or CEV (Combat engineering vehicle), was a vehicle dedicated to recover battle damaged or broken down tanks during combat, saving them to receive more extensive repairs behind the frontlines. The first true ARVs appeared in World War Two, seeing service with most nations, and thus, even despite mass production, which could have meant "dispensable" items. But since there was a shortage of armour even with the allies, and to compensate for the losses of material sunk in convoys, many tanks dsabled in battle were still repairable or at least, constituted a reserve of spare parts and can be cannibalized. The United States was no exception to this reasoning.US Army Recovery and Repairs Management

The British already had some experience in this, as well as the Germans during WW1 already: The Germans started to recover captured Tanks, using artillery tractors, while some British Mark IV heavy tanks were fitted with jibs to produce "salvage tanks". They constituted Tank parks for moving, maintaining, and repairing damaged tanks, saving some production spending and setting up an embryo of organization. All this however was forgotten in the peacetime years that follows, sleeping in report folders and archives. The US Army never really had time to setup a similar organization, already late to constitute armoured units and engage them. The interwar budget cuts and isolationist policy curtailed efforts to rebuilt a significant tank force, despite considerable literrature was written and prototypes were created and tried between Rockland arsenal and Aberdeen proving grounds. The need for such organization was tied to an engagement in the field.

After WW2 broke out, the British once again revived this organization, but only in the campaign in North Africa. The USA were engaged in the Pacific where tank use was difficult, but in Europe, starting in November 1942, agai in North Africa, and after experiencing reverses such as at Battle of Kasserine Pass in Tunisia, recovering tanks became an important task. This task fell out naturally under the large perimeter of the Ordnance Corps, which had to supply Army combat units, procure them, but also maintain them in the field. Sub-units were the Quartermaster Corps and Transportation Corps, part of the U.S. Army logistics system which proved critical in WW2. This service used occasionally a tractor for towing artillery like the M6/M6 HS Tractors, trucks like the Mack NO4/5 7½-ton 6x6 truck, International H542-9 4×2 Tractor Truck+ Fruehauf CPT-22 semi-trailer, C2 Wrecker, or the heavy dury M26 ARV truck. But battlefield conditions was a gift to tracked vehicles, especially when the battleline was close and fluctuating. And armoured recovery vehicle became an evidence, but rather than desining a decicated vehicle it was decided to convert and existing one. The first chosen was the M31.

Basis: The M3 Lee

The Medium Tank M3 lee (Grant in British service) was a welcome addition to the hard-pressed British army in north africa and the first standard medium tank delivered by USA during WW2, in significant numbers. Obsolete at the end of 1942, it went on soldiering in the far east and its chassis found many application, including the next standard M4 Sherman. Critized for its light gun and hull mounted howitzer reminsicent of the earlier French B1 and other designs, it was seen as a stopgpap tank, before the M4 could be ready. Of the numerous applications of his hull, were the following:- M31 Tank Recovery Vehicle (Grant ARV I)

- M31B1 TRV, Based on M3A3

- M31B2 TRV, Based on M3A5

- M33 Prime Mover M31 converted to the artillery tractor role

- 105 mm Howitzer Motor Carriage M7 (Priest) The standard SPH

- 155 mm Gun Motor Carriage M12 T6 155 mm howitzer on M3 chassis

- M30 Cargo Carrier use with it, same chassis

Development design of the T2

Almost immediately after the start of the production of the M3 medium tank, the Ordnance Department started to experiment with specialized chassis conversions. One direction was the creation of a full tracked prime mover, for towing heavy artillery. In April 1942, Baldwin Locomotive Works delivered 2 prototypes, pilot models assigned in the nomenclature "Heavy Tractor, T16." They were testes in the Californian Desert Training Center. Report found it unsuitable due to a lack of stowage space. In the Summer of 1942, the Desert Warfare Board however was given instruction to test the T16 this time as Tank Recovery Vehicle. First tests shown on T16 recover the other one, and the more recent M26 Tank Transporter truck. T16s evolved in the meantile with more advanced M3 production versions, and the next prototypes had a diesel engine, converted from M3A5 Lee chassis. They were fitted with a 40000 pound capacity winch mounted on the lower rear, creating a tripod arrangement. The arm was supported by a dual muffler assembly, relocated to the engine deck. Tests proved successful, after which, the DTC, in agreement with Aberdeen Proving Ground, suggested making a standardized Tank Recovery Vehicle based on the latest M3 Medium chassis. In August, 1942, the ordnance place a first order for 100 of the new M3A3/M3A5s, and while 100 other M3 Lees from the battlelfueld, damaged and repairs, were released to Baldwin for conversion as "Heavy Tractor, T16." in part to perform more tests.Standardization of the M31 ARV

The new Recovery Vehicle designated "T2 by late September 1942 received the approval for production, a total order to Baldwin for 750 units, 150 converted M3A3/M3A5 diverted from its regular M3 Production line, and the other 600 (later 509) were recovered M3 to be repaired, reconditioned and converted from the field. This went way beyong the simple fitting of accessories. They were retrofitted with the new 80 Octane R-975-C1 Radial engin combined with the "high engine outlet exhaust" standard on the M4/M4A1 Sherman as well as the "the Lipe type clutch".Baldwin completed its initial M3 Grant contract (685 units in July 1942) and its 685 M3 Lee in December, 1942, later reduced by 150 units, to be converted as the T2 Diesel TRV.

Production went on from November 1942 to December 1944, so the M31 was very much around in 1945, on all fronts.

The first production run concerned 150 vehicles (Order T-6867) at Baldwin Locomotive Works, from November 1942 to 1943. These B1/B2 all run with diesel engine.

The second, larger parralel run (order T-4417) concerned converted earlier M3 Lee with gasoline engines. In total 509 were so converted. It run from October 1942 to December 1943, so for more than a year.

A part of these also ended on the eastern front via lend-lease, with a dedicated production (order T-8871) and this concerned 146 B1/B2 diesel models. This order ran from August to December 1943.

Design

The first 108 units was finalized by late 1942, while the remaining conversions varied for minor details due to their origin and because tests were conducted along the way and modifications applied during the production run over a year, until the end of 1943. The Ordnance Department wanted an optimistic deadline: 750 T2s produced by April 1, 1943. But in March, only 163 units were converted. Gar Wood Industries was the manufacturer of the winches and booms installed on the vehicle, and that was created a bottleneck due to an acute labor shortage in Detroit. The delivery of components was delayed. The despite the situation was reported to the government, which in turn imposed a greater priority to the T2 program this did not change the labor shortage problem. Baldwin completed its conversion program by December 1943, for a grand total of 805 units.Outside the engine and exhaust for the conversions, the B1/B2 production vehicle was a late M3, with no side hatch and welded assembly for the superstructure. The T16 pilot was shipped with its original late production M3 Lee stowage, later modified. Named "Karinka" this T2 TRV was delivered to the Armored Force Board at Ft. Knox by November 1942, with a welded assembly and diesel engine of the late production run. The turret was removed, and replaced by a smaller, round cast model, with one almost flat sloped face, from which emerged the main boom. The latter was fixed on a pivot fitted either sides of the turret opening, and cabled went on internally to a first free winch, when was connected to the main winch below. The 60,000 pound capacity Gar Wood winch was therefore in the crew compartment for safer service, directly below the turret. The winch cable was also threaded under the vehicle for support of heavy loads, so the whole vehicle's weight was used to counterbalance the load. The 360° capable turret allowed the boom to be oriented and perform recovery operations at the front or rear. The lifting was assured by a crane assembly, mounted on a plate fitting the original M3 Lee 37mm gun mount turret ring. Total lifting capacity was 10,000 pounds or 5 tons without boom jacks, and 30,000 pounds with them, mounted on ground base. In mid-1942, changes on the M3 Lee production run such as the elimination of side doors and addition of 3 ventilators, which were found on the T2 "Katrinka" pilot.However the majority of the converted vehicles were earlier production with working side doors, but welded up during conversion.

Second point was the "mobile shop" arrangement of the left side stowage cabinets. The boom assembly was bolted to the Lee turret, but it was soon found a weak part, due to looseness in the turret's retaining race, and inadequate traversing mechanism. Lifting operations on the sides were fobidden. Two adjustable boom jacks were used to create a tripod, eother at the back of rear, and they were stowed while on the move in in their traveling position on the boom assembly. The boom jack pin assemblies were welded onto the support angle at the vehicle's center line initially, but it was relocated offset from the right edge of the support angle in production. There were also fittings for a pair of spare return rollers on the support angle between the pin assemblies. The back plate was modified, much taller and mounted on an angle for those equipped with the GM twin diesel engine power pack. It provided partial protection for two radiators and a muffler assembly. It was secured by a line of slotted bolts holding the removable rearmost engine deck section. There was also an extra storage, provided by a secon stowage assembly in front, front of the rear stowage bins. The other side was left free to access the main gasoline filler port. Later in production, a jack assembly was welded on the lower front plate of the M3 to allow the vehicle to be towed. Additional stowage was often installed above the sponson, and spare tracks were stored on the rear of the rear stowage boxes, starting in mid January 1943, in place of the usual shovel, which was relocated.

Protection

The protection figures were the same as the regular M3/M3A3/M3A5 Lee: 51 mm (2.0 in) for the hull front, turret front, sides, and rear and 38 mm (1.5 in) fof the sides and rear casemate. The cast turret had likely the same figure, 38 mm and was very similar in shape to the original turret. It should be noted than a few refurbished early production M3s had a driver's periscope as requested in the British production run. Baldwin by the way was the only manufaturer of both the M3 Lee and Grant simultaneously. Also no side door would constitute a weak point, they were all welded shut. The cast turret was in production given a hatch (British contribution to the T2 design). Simple with two-pieces opening, there was no associated persicope. There was however a pintle mount for the .30 caliber anti-aircraft machine gun, fired by the tank commander from inside the turret. There was also a pintle to mount a spot lamp. This this turret does not have a ventilator, but possessed a single vision slit. Due to the mention of the M3A1 cast hull version in the T2 manual suggest at least some of these may have been converted. But this is not confirmed by photos.Armament

The original design of the M3 Medium included two fixed .30 caliber mounted in the bow, left of the driver's seat. Due to their poor effectiveness by June 1942 one was eliminated. The T2 Technical Manual shows the single cal.30 gun arrangement at the driver's position. The second port was filled in with a plug. This was the only M31 TRV permanent weapon. There was none, but the crew's own personal guns, but with time, a pintle mount was installed, either on the turret for a cal.50 or Cal.30 AA, or on the left side of the hull, for a cal.50. A pair of dummy guns were welded on the left sponson, of the turret's back in an attempt to conceal the vehicle's purpose.Powerplant & mobility

The powerplant varied: Diesel on the B1/B2 (see the M3A1 and A5 for specs), which concerned only a lesser part of the total order, and earlier gasoline engines for the main production run, later retrofitted to the new Gasoline engine. It was discovered when testing the third pilot converted from a M3A5, that its volute springs were overloaded during lifting operations. During production therefore, the heavy duty M4 type bogies were obtained and became standard for the conversion from October, 1942, but the retrofitting with M4 bogies was not done, none could be spared from the very urgent M4 production. Nevertheless, the 497 M3 series Medium Tanks remanufactured and converted to Canal Defense Lights received a higher proriotiy in 1944 and were retrofitted with M4 bogies. Baldwin however seemed to have retrofitted "pillow blocks" or "spacers" to its T2 conversions in order to raise the return rollers up by an inch.Video

M31 ARV specifications | |

| Dimensions (L-W-H) | As M3 |

| Crew | Driver, Commander, 1 assistant |

| Propulsion | see notes |

| Top speed | As M3 Lee |

| Maximum range | As M3 Lee |

| Armament | 1-2 0.3 cal MG or single cal.05 M2HB HMG |

| Armor | As M3 Lee |

The M31 ARV in action

It is obvious from photos became the main TRV at the end of the campaign of the the Mediterranean. Early shipments of T2s were over 300, running on gasoline engines. The diesel versions M3A3, M3A5 and M4A2, were not approved for overseas use, but supplied to the Allies as Lend Lease instead, with the latter exception of the M10 Tank Destroyer. Diesel T2s eventually made it to the battlefield as theyr were available and needed. The first serie were not directly integrated into the North African landings (Operation Torch), but were accepted in April, 1943 and therefore started operations in the Tunisian campaign, the battle if Tunis and Sicilian landing. They were alo seen in action in Italy with the VIth Corps at Anzio in May 1944. In a single day Combat Command B's attack east of Cisterna failed and disabled 23 Shermans and 7 Tank Destroyers in an uncharted minefield were to be retrieved. At least one the 1st Armored Division's Maintenance Battalion was damaged in this minefield during operations.In 1944, they were still shipped, whereas the M32 ARV, based on the Sherman was already tested and standardized, scheduled to replace the M31. The latter went into production for the US Army in December 1943. The first of these arrived in the UK in early 1944, starting to be used when the supply of T2s was depleted. The M32 became the standard retreiver in the second half of 1944 to the end of the campaign in Europe.

Early on also, M31 TRV were shipped to at least one of the three armoured divisions that were setup for the French army in North Africa, until then which had to make due with French vintage tanks and vehicles. It is impossible to give details about the number or type, but their presence with the FFL was attested by numerous photos.

From the Summer of 1943, about 150 T2s were shipped to the UK to prepare for D-Day operations. These vehicles came from June-September 1943 conversions. These were at last 49 diesel T2s on this, distributed to the first US Armored units stationed in the UK notably the 2nd and 3rd Armored Divisions, 70th, 741st, 743rd, 745th and 746th Tank Battalions. Some T2s took part in the the first US amphibious training operation conducted in England, from the 1st Engineer Special Brigade, trained to exploit a beachhead after the initial assault. At D-Day, the first days, 741st T2s were hard at work in perilous conditions.

Eventually the T2s and their crews served with distinction until 1945, but were designated already this summer "Limited Standard," so to be used until failure with no replacement or repair. Well before, the M32 series were designated "Standard" on October 7, 1943. Attrition rate was lower, and this was due to their action in the rear lines, quieter in general. But there were losses, such as the vehicles from the 3rd Armored Division soldeiering in July 1944 in Normandy. While attempting to recover a damaged Sherman, it appare,tly roller on a mine. By that time, the crews needed a quick protection in case of a ground attack, and many were armed in the field with a .50 caliber machine gun on a side pintle, or one installed on the roof. This became even more evident for thos used in Germany in 1945 as the front lines were fluctuating. Some were still active shown in photos at Wingen-sur-Moder (Alsace Lorraine) during Operation Nordwind in January 1945, and they carried unorthodox hardware to perform field repair.

The Soviet Union was "officially" allocated and shipped T2s, although little is known about their with Soviet armored units. This concerned a August-December 1943 batch of 146 diesel T2s but 115 were listed received as Lend Lease, with 31 probably lost at sea in the Murmansk road. These vehicles were given the registration Numbers 751, USA 40142501 through 896, USA 40142646.

No M31 was sent in the Asian theater, but the apparented "Grant ARV" a field conversion by the British based on the Kangaroo M3. However the French officially received 175 M32 series and 29 T74/M51 TRV as post war assistance and part of these saw action on Indochina, which had five M32 in 1954. At least one T2 was used in Indochina according to a photo taken in January 1952 in the Tonkin. It was used by the Régiment Blindé Colonial d'Extrême-Orient before hitting a Viet Minh mine which cracked open its superstructure. It has been retrofitted with an M4 bogie.

Illustrations

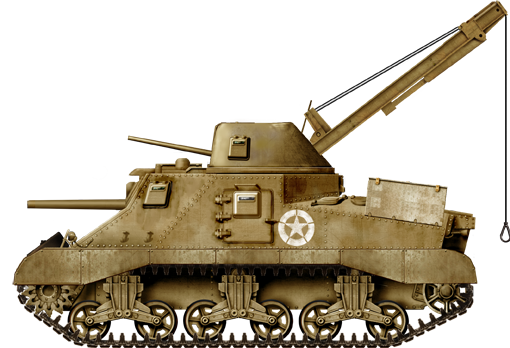

M31 in full experimental sand camouflage, Tunisia, December 1942

M31 ARV in Tunisia, Jan-March 1943

M31 with its desert camouflage, El Guettar, March 1943

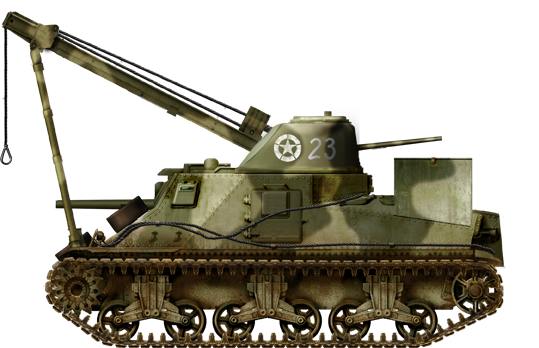

M31 ARV "go get it" of G Company, 66th Armored Regiment, 2nd Armored Division in Bizerte, July 1943. It was later seen in Sicily.

Camouflaged M31 in Sicily, July 1943

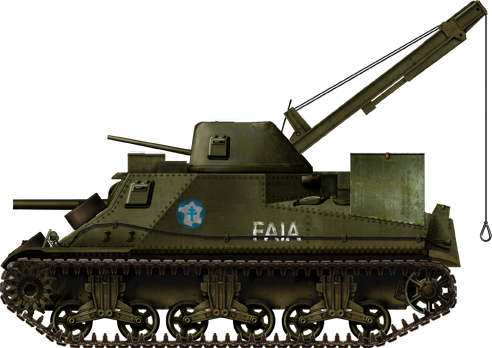

M31 in Italy, March 1944

M31B1 in Italy, April 1944

M31 used by the FFM (Free French), Provence Landings, August 1944

More photos

July 2, 1943 Bizerte Harbor (Tunisia), TRV part of G Company, 66th Armored Regiment, 2nd Armored Division assembled for the landings of Sicily. Seen on the.shadock.free.fr - photo from the sherman minutia.

July 2, 1943 Bizerte Harbor (Tunisia), TRV part of G Company, 66th Armored Regiment, 2nd Armored Division assembled for the landings of Sicily. Seen on the.shadock.free.fr - photo from the sherman minutia.Links/Src

https://commons.wikimedia.org/wiki/M31_ARVhttp://the.shadock.free.fr/sherman_minutia/tankrecovery/m31_trv.html

https://www.how-amps.org/m31-t2-tank-recovery-vehicle

http://www.historyofwar.org/articles/weapons_M31_tank_recovery_vehicle.html

http://the.shadock.free.fr/sherman_minutia/tankrecovery/m31_trv.html

http://ftp.olive-drab.com/idphoto/id_photos_tankrecovery_t2.php

http://panzerserra.blogspot.com/2014/12/m31-t2-tank-recovery-vehicle-part-01.html

http://afvdb.50megs.com/usa/trvm31.html

http://panzerserra.blogspot.com/2016/01/m32b1-tank-recovery-vehicle-case-report.html

http://the.shadock.free.fr/sherman_minutia/tankrecovery/m32_trv.html

trucks http://www.twinbeech.com/federalc2wrecker.htm

WW2 Tanks

WW2 tanks posters

All Tiger tanks liveries.

Panther liveries and variants

WW2 Armour - All tanks

Tanks aces and single tanks series

Find more there

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com