The MT-55 based on the Czech-built T-55 Main Battle Tankunder licence and was designed and produced by ZŤS Martin from 1962, with the development phase going on until 1967 followed by five pre-series vehicles. The MT-55A (Base T-55A) series production started in 1969 and went on until 1982 with a total of 1,762 vehicles in four variants, including 183 export MT-55KS and 458 East German BLG-60. It was also exported to Belarus, Egypt, Croatia, Georgia, India, Iraq, Myanmar, North Korea, Romania, Serbia, Slovakia, Slovenia, Sri Lanka, Syria, and Ukraine.

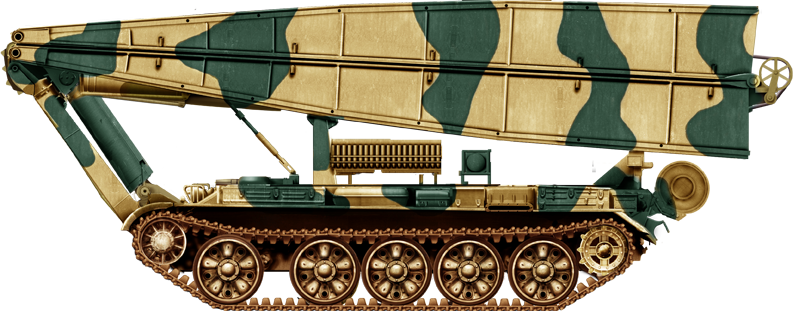

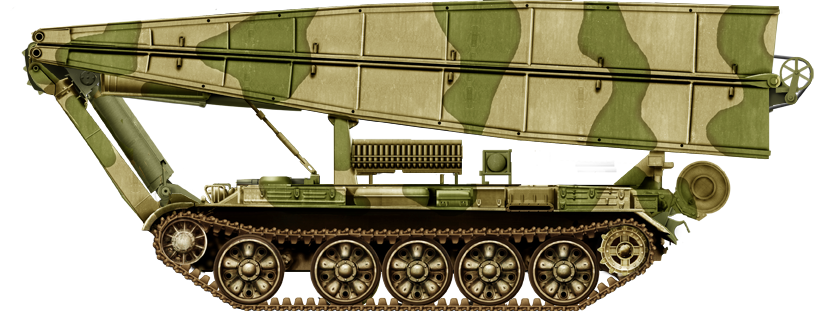

Iraqi MT-55, 1990

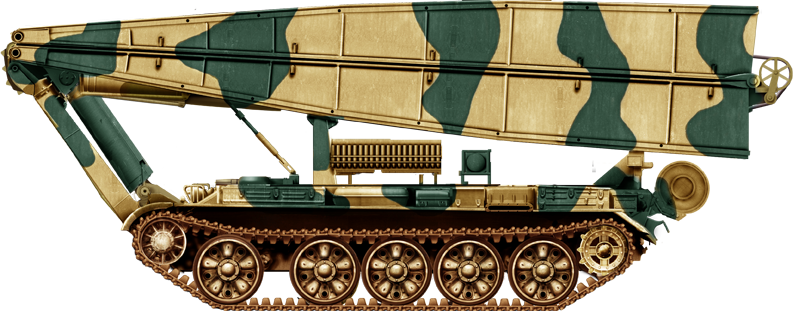

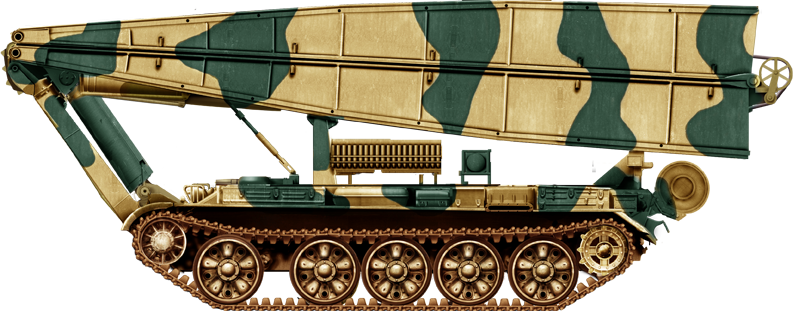

Ex-Syrian AVLB at Latrun

The Soviet Union's invasion of the West scenario intended a deep penetration in Germany preceded by large paradroppings in order to secure bridges by a much beefed-up VVS provided with amphibious and airborn armoured vehicles of several types. The need for bridgelayers was thus much reduced, and only considered for modified specialized trucks. Still, there was at least one in service, the BTT-1 based on a SU-152 chassis. However at some point in 1960, Czechoslovakia proposed for an easy and swift crossing of antitank barriers and other obstacles instead of rivers to facilitate the passage of mechanised and tank units. This resulted in the creation of an armoured vehicle based on an existing, readily available and widespread chassis.

Research and development work started at J.V. Stalin Factory in Martin in 1961 based on an agreement of principle tactical requirements of the MNO (Czech Army Engineer Army Command) which wete sent to the ZTEES Martin directorate. It was understood a 18 m span and Rieka deep wading device from the start as well as to base it on the nexly licenced T-55 chassis which offered an NBC protection.

In 1962-63, two functional protototypes based on the T-55 which licence was just acquired, were produced. They were extensively tested at the end of 1964, reports were followed by fixes and the creation of a final prototype with more extensive state tests carried out in 1965-66. VOP 025 Nový Jičín and other companies collaborated and by the end of June 1964, the final project was completed, according to which a prototype vehicle was produced by December. Functional tests with the prototype began in February 1965, interrupted by an accident of the laying mechanism and further modifications. All control tests took place in Martin from June to the October 1965.

The prototype ran on Liptovská Mara dam with a bridge for 1,500 km, and without a bridge for 500 km but issues were detected in the hydraulic system. The modified prototype was tested again on July 1, 1966, driving over 200 km. Problems were observed with the bucket of the laying mechanism breaking as well as the rear support bracket, and so further modifications and tested were made until Martin announced all issues fixed on May 1967. The final development was declared completed in May and a verification preserie was signed for 5 vehicles in 1968, but delayed as further tests revealed issues in October 1967.

After further field tests between February 1 to April 24, 1968, preserie constructon was authorized for operational conditions tests. serial production was approved and started after retooling and a dedicated production line setup in 1969. On prototype was preserved at VOP 025 Nový Jičín and another at the Military Academy in Brno. The remaining three preseries were tested by the 1st armoured division until 1973. Documenation for mass production was agreed upon in Dember 1969.

Additional copyright certificates related to the construction of the superstructure were delivered. Deliveries were intended, as for the T-55 for the entire Warsaw Pact, Soviet Union included. At first, deliveries to the Czech Army represented about 15% (1,270 in other sources). Exports amounted for about 65% and foreign exports went to about 20% in total. This represented a solid income source for Czechoslovakia for most of the cold war, as until its replacement by a T-72 based AVLB, called MTU-72 (Bridgelayer) in USSR by 1974, the MT-55 remained the primary organic AVLB of Warsaw Pact armoured divisions.

The MT-55 is essentially a turretless T-55 chassis, first production of 1962, which integrated the advances of the T-55, notably a nuclear-bactoriological and chemical collective protection (NBC) as well as the original hull armour of the T-55, which included a 100 mm upper glacis sloped at 60° and 100 mm at 55°. The back plate was divided into three sloped sections at 30, 45 and 20 mm at 60/17/70°. There was a bulkhead between the engine and fighting compartment. The engine deck was nearly unprotected at 15°. The fighting compartment was now replaced by an operator's display to operate the bridge laying frame, with the entire bridge and its support and dependencies being unprotected. The MT-55 was too "busy" to be armed, and the crew was reduced to the driver and operators, both having their own personal weapons. The MT 55 A is also capable of crossing a one kilometer water obstacle using a wading gear down to 4 m, even with a loaded bridge thanls to the "RIEKA" device.

The transformed T-55A chassis had different compartments built inside the hull and its equipment was controlled by hydraulic cylinders, with the level of hydraulic oil controlled both manually by mechanical levers and automatically. The pressure was provided by high-pressure piston pumps driven by the main engine. All mechanisms could be controlled by operator from inside with hatch closed. The load capacity of the bridge unfolded in place was 50 t but the max possible span of the bridged obstacle should stay inferior to 17.5 m as it measured 18 m by 3.3 m (60 x 19.7 ft) for 6,5 tons. It took 3 min to lay off the bridge, from unfolding to placement, and 5-8 min. to refold it back in place for transport. Its main laying mechanism comprised 4-joint fully hydraulic cylinders with electric automated process wether for laying or loading.

There was a precise rangefinder to determine the span of the obstacle and so find the best location to gap it. It shen stopped short of the gap, the bridge swang ahead and down and the two sections open like scissors. It had apertures to fix it solidly in place using hammered pikes if needed, especially for sloppy embankments. Later, the MT-55A's gap rangefinder was added an infrared sight to operate in darkness.

For close defense, the crew had at its disposal a Submachine gun vz.58, 15 Hand grenades and a Signal gun. The vehicle came with a short range R-123 emetter/receptor and an internal on-board electric network of 24 V. The pressurized oil for the hydraulioc system used ACK-16-7 pumps with heating provided by a heat exchanger ciculating warm water via the engine's cooling and heating system. In all there was a reserve of 50 liters working at a pressure of 21.5 MPa (220 kp/cm2), max 27.5 MPa (280 kp/cm2) and the whole reserve being of 350 liters. It was commanded from a switchboard in six sections with two controlled safety valves.

MT-55A: Standard production model.

MT-55KS (Kapitalstické Státy): Export model for non-Warsaw Pact countries without NBC pritection.

PM-55 (Přepravník Mostu): Wheeled version based on a Tatra 813 "Kolos". Belarus (55A)

Belarus (55A)

Egypt MT-55KS

Egypt MT-55KS

Croatia: MT-55A

Croatia: MT-55A

Czech Republic: MT-55A

Czech Republic: MT-55A

Georgia: MT-55A

Georgia: MT-55A

India: MT-55KS but locally called the MT-55

India: MT-55KS but locally called the MT-55

Iraq: MT-55KS

Iraq: MT-55KS

Myanmar: MT-55A

Myanmar: MT-55A

North Korea, likely MT-55KS

North Korea, likely MT-55KS

Romania: MT-55A

Romania: MT-55A

Russia: MT-55A ("MTU-55")

Russia: MT-55A ("MTU-55")

Serbia: MT-55A

Serbia: MT-55A

Slovakia: MT-55A

Slovakia: MT-55A

Slovenia: MT-55A

Slovenia: MT-55A

Sri Lanka: 8 MT-55As in 2000 from the Czech stocks with 40 T-55AM2.

Sri Lanka: 8 MT-55As in 2000 from the Czech stocks with 40 T-55AM2.

Syria: MT-55A/KS

Syria: MT-55A/KS

Ukraine: MT-55A.

Ukraine: MT-55A.

The MT-55 was largely exported, and if not seeing action with the Warsaw Pact, it saw combat with Egypt and Syria in 1967 against Israel that was able to capture a small number of MT-55KSs, using them with some small modifications. They came from Southern front, Gaza and Sinai Peninsula during the Six day war. It's not sure they did saw action in 1973 however, but some saw combat in the 1990 Gulf war as part of the Iraqi army, and others saw action in the Balkan civil war of the 1990s, being part later of the successors states, Croatia, Serbia, Slovenia, all MT-55s.

Those detained by India saw action during the 1971 Indo-Pak war as well, others detained by Sri Lanka and Myanmar also saw action, and the Georgian ones during the Russo-Georgian war of the 2000s. Today, Belarus, Russia and Ukraine still possesses a number of these, albeit operational status is unknown. In Russia it was likely replaced by the MTU-72 AVLB.

Iraqi MT-55, 1990

Design

Development

Ex-Syrian AVLB at Latrun

The Soviet Union's invasion of the West scenario intended a deep penetration in Germany preceded by large paradroppings in order to secure bridges by a much beefed-up VVS provided with amphibious and airborn armoured vehicles of several types. The need for bridgelayers was thus much reduced, and only considered for modified specialized trucks. Still, there was at least one in service, the BTT-1 based on a SU-152 chassis. However at some point in 1960, Czechoslovakia proposed for an easy and swift crossing of antitank barriers and other obstacles instead of rivers to facilitate the passage of mechanised and tank units. This resulted in the creation of an armoured vehicle based on an existing, readily available and widespread chassis.

Research and development work started at J.V. Stalin Factory in Martin in 1961 based on an agreement of principle tactical requirements of the MNO (Czech Army Engineer Army Command) which wete sent to the ZTEES Martin directorate. It was understood a 18 m span and Rieka deep wading device from the start as well as to base it on the nexly licenced T-55 chassis which offered an NBC protection.

In 1962-63, two functional protototypes based on the T-55 which licence was just acquired, were produced. They were extensively tested at the end of 1964, reports were followed by fixes and the creation of a final prototype with more extensive state tests carried out in 1965-66. VOP 025 Nový Jičín and other companies collaborated and by the end of June 1964, the final project was completed, according to which a prototype vehicle was produced by December. Functional tests with the prototype began in February 1965, interrupted by an accident of the laying mechanism and further modifications. All control tests took place in Martin from June to the October 1965.

The prototype ran on Liptovská Mara dam with a bridge for 1,500 km, and without a bridge for 500 km but issues were detected in the hydraulic system. The modified prototype was tested again on July 1, 1966, driving over 200 km. Problems were observed with the bucket of the laying mechanism breaking as well as the rear support bracket, and so further modifications and tested were made until Martin announced all issues fixed on May 1967. The final development was declared completed in May and a verification preserie was signed for 5 vehicles in 1968, but delayed as further tests revealed issues in October 1967.

After further field tests between February 1 to April 24, 1968, preserie constructon was authorized for operational conditions tests. serial production was approved and started after retooling and a dedicated production line setup in 1969. On prototype was preserved at VOP 025 Nový Jičín and another at the Military Academy in Brno. The remaining three preseries were tested by the 1st armoured division until 1973. Documenation for mass production was agreed upon in Dember 1969.

Additional copyright certificates related to the construction of the superstructure were delivered. Deliveries were intended, as for the T-55 for the entire Warsaw Pact, Soviet Union included. At first, deliveries to the Czech Army represented about 15% (1,270 in other sources). Exports amounted for about 65% and foreign exports went to about 20% in total. This represented a solid income source for Czechoslovakia for most of the cold war, as until its replacement by a T-72 based AVLB, called MTU-72 (Bridgelayer) in USSR by 1974, the MT-55 remained the primary organic AVLB of Warsaw Pact armoured divisions.

Hull and protection

The MT-55 is essentially a turretless T-55 chassis, first production of 1962, which integrated the advances of the T-55, notably a nuclear-bactoriological and chemical collective protection (NBC) as well as the original hull armour of the T-55, which included a 100 mm upper glacis sloped at 60° and 100 mm at 55°. The back plate was divided into three sloped sections at 30, 45 and 20 mm at 60/17/70°. There was a bulkhead between the engine and fighting compartment. The engine deck was nearly unprotected at 15°. The fighting compartment was now replaced by an operator's display to operate the bridge laying frame, with the entire bridge and its support and dependencies being unprotected. The MT-55 was too "busy" to be armed, and the crew was reduced to the driver and operators, both having their own personal weapons. The MT 55 A is also capable of crossing a one kilometer water obstacle using a wading gear down to 4 m, even with a loaded bridge thanls to the "RIEKA" device.

Chassis, engine and drivetrain

The vehicle was powered exactly like the regular T-55, with the same V-55 12-cyl. 38.88 liter water-cooled diesel rated for 580 hp (430 kW), which meant that for 36 tonnes in maching order, made for a Power/weight ratio of 11,83 kW/t or 14 hp/tonne. It was equipped with the same drivetrain, 5-speed gearbox, with front idlers, rear drive sprockets, five readwheels per side with not return rollers and double pin tracks, un-ruberrized. The five axles were suspended on torsion bar. Operational range is estimated 580 km (On roads with 910L fuel) for a top speed of 50 km/h. The overall vehicle was larger, longer and taller than the original T-55 at 9,880 mm in length, 3,300 mm in width and 3,350 mm tall with span.Detailed design

The transformed T-55A chassis had different compartments built inside the hull and its equipment was controlled by hydraulic cylinders, with the level of hydraulic oil controlled both manually by mechanical levers and automatically. The pressure was provided by high-pressure piston pumps driven by the main engine. All mechanisms could be controlled by operator from inside with hatch closed. The load capacity of the bridge unfolded in place was 50 t but the max possible span of the bridged obstacle should stay inferior to 17.5 m as it measured 18 m by 3.3 m (60 x 19.7 ft) for 6,5 tons. It took 3 min to lay off the bridge, from unfolding to placement, and 5-8 min. to refold it back in place for transport. Its main laying mechanism comprised 4-joint fully hydraulic cylinders with electric automated process wether for laying or loading.

There was a precise rangefinder to determine the span of the obstacle and so find the best location to gap it. It shen stopped short of the gap, the bridge swang ahead and down and the two sections open like scissors. It had apertures to fix it solidly in place using hammered pikes if needed, especially for sloppy embankments. Later, the MT-55A's gap rangefinder was added an infrared sight to operate in darkness.

For close defense, the crew had at its disposal a Submachine gun vz.58, 15 Hand grenades and a Signal gun. The vehicle came with a short range R-123 emetter/receptor and an internal on-board electric network of 24 V. The pressurized oil for the hydraulioc system used ACK-16-7 pumps with heating provided by a heat exchanger ciculating warm water via the engine's cooling and heating system. In all there was a reserve of 50 liters working at a pressure of 21.5 MPa (220 kp/cm2), max 27.5 MPa (280 kp/cm2) and the whole reserve being of 350 liters. It was commanded from a switchboard in six sections with two controlled safety valves.

Specifications MT-55 | |

| Dimensions | 9,880 mm oa x 3,300 mm oa x 3,350 mm oa |

| Total weight | 36t |

| Crew | 3 (driver, operator/cdr) |

| Propulsion | V-55 12-cyl. 38.88l wc diesel 580 hp (430 kW) pw 14 hp/t |

| Suspension | Torsion bar |

| Speed (road) | 50 km/h |

| Range | 580 km (On roads) |

| Armament | None (personal weapons) |

| Armor | As T-55A, NBC, same armour |

| Total production | 1762 (183 exports, 458 hulls for BLG-60) |

Variants & Operators

MT-55: Pre-series model using the MT-34 bridge. Initially called by NATO as a MT-55L variant.MT-55A: Standard production model.

MT-55KS (Kapitalstické Státy): Export model for non-Warsaw Pact countries without NBC pritection.

PM-55 (Přepravník Mostu): Wheeled version based on a Tatra 813 "Kolos".

Operators

Belarus (55A)

Belarus (55A) Egypt MT-55KS

Egypt MT-55KS Croatia: MT-55A

Croatia: MT-55A Czech Republic: MT-55A

Czech Republic: MT-55A Georgia: MT-55A

Georgia: MT-55A India: MT-55KS but locally called the MT-55

India: MT-55KS but locally called the MT-55 Iraq: MT-55KS

Iraq: MT-55KS Myanmar: MT-55A

Myanmar: MT-55A North Korea, likely MT-55KS

North Korea, likely MT-55KS Romania: MT-55A

Romania: MT-55A Russia: MT-55A ("MTU-55")

Russia: MT-55A ("MTU-55") Serbia: MT-55A

Serbia: MT-55A Slovakia: MT-55A

Slovakia: MT-55A Slovenia: MT-55A

Slovenia: MT-55A Sri Lanka: 8 MT-55As in 2000 from the Czech stocks with 40 T-55AM2.

Sri Lanka: 8 MT-55As in 2000 from the Czech stocks with 40 T-55AM2. Syria: MT-55A/KS

Syria: MT-55A/KS Ukraine: MT-55A.

Ukraine: MT-55A.

The MT-55 in action

The MT-55 were given to tank regiment level inside tank divisions, but also at the tank battalion level of motorized rifle regiments, and engineer battalions at engineer brigades level. They were designed mainly to overcome anti-tank ditches as well as anti-tank walls and slopes but also natural obstacles as part on an uneven terrain, or artificial obstacles created by explosives (craters) and narrow rivers. Tactically, the MT-55 could not be air-transported, but by rail on two sections, chassis and bridge or on two truck trailers with a load capacity of 20 t.The MT-55 was largely exported, and if not seeing action with the Warsaw Pact, it saw combat with Egypt and Syria in 1967 against Israel that was able to capture a small number of MT-55KSs, using them with some small modifications. They came from Southern front, Gaza and Sinai Peninsula during the Six day war. It's not sure they did saw action in 1973 however, but some saw combat in the 1990 Gulf war as part of the Iraqi army, and others saw action in the Balkan civil war of the 1990s, being part later of the successors states, Croatia, Serbia, Slovenia, all MT-55s.

Those detained by India saw action during the 1971 Indo-Pak war as well, others detained by Sri Lanka and Myanmar also saw action, and the Georgian ones during the Russo-Georgian war of the 2000s. Today, Belarus, Russia and Ukraine still possesses a number of these, albeit operational status is unknown. In Russia it was likely replaced by the MTU-72 AVLB.

Gallery

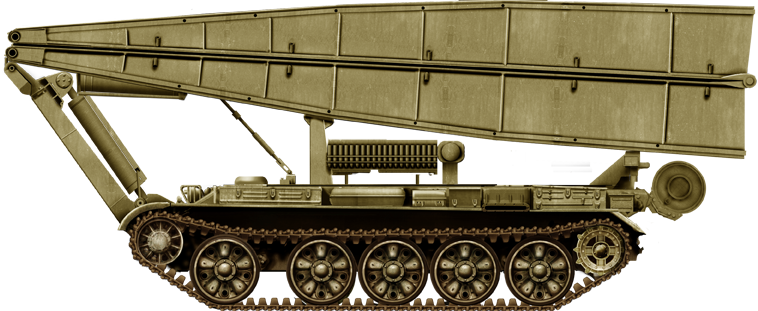

Regular Czech Vehicle, 1960s

Egyptian MT-55, 1967

Syrian MT-55, 1967

Iraqi MT-55, 1990

More photos

MT-55 at the Mil. History Park, Pivka.

Latrun's museum MT-55 showing the forward extended hydraulic arm and the bridge lowered, ready to lay down.

Rear of the ex-Syrian MT-55 in Israel, with the rear support and utility back stowage.

Same, front view, note the commander's position on the right, with a two periscopes. Note alsi the pilars and table on the main deck and absence of the former ring mount, replacfed by a completely new compartment.

At the Bundesmuseum Dresden

Sources

valka.cz/army.cz

T813 PM-55/T813 8x8 "KOLOS"

tau.ac.il

grada.cz

armyrecognition.com

stef124.tripod.com/mt55.htm

idf-armour-group.org/

panzermodelkit.valka.cz

dishmodels.ru

commons.wikimedia.org

en.wikipedia.org/wiki/MT-55

Videos

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com