The Merkava Mk 2 Main Battle Tank was a successor to the Mk 1, initiated after the long search for a new modern tank for the IDF, led by Israel Tal. It entered service with the Israeli Defence Force in 1983 and was produced more as lanufacturing capabilities increased with a total of 580 from 1982 to 1989. This was the last Merkava of the cold war, with gradual improvements to its protection from lessons of the 1982 Lebanon War. It has been upgraded and re-designated since entering service wit the latest being the Mk2D as of 2023, tasked with training units but still mobilizable in case of war.

Mark I in Latrun museum

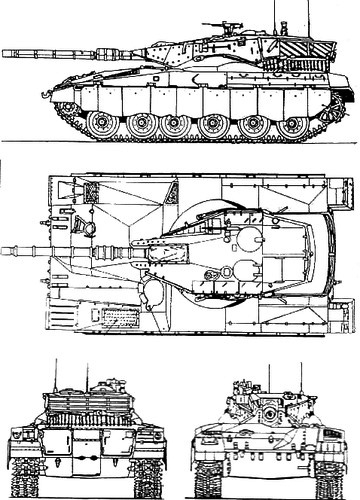

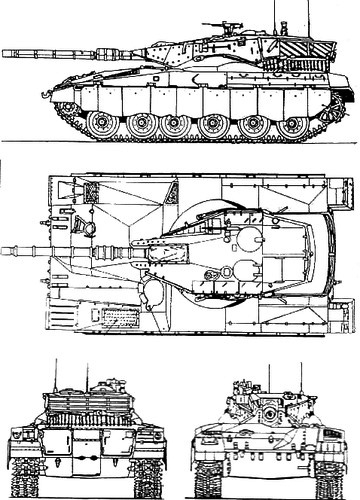

Merkava 2, same, note the different exhaust, different side skirt, new pannier, rood sensors, IR searchlight, addon nose and turret armour, ect.

We are not going to retrace here all the long development of the Merkava, a project that went all the way back to the 1967 6 days war, with a serious start after the 1973 Yom Kippur war and crippling tank losses for the IDF in one engagement. Veteran general Israel Tal led the project. The project was tailored for the middle-eastern theatre of war, also planned to reuse existing platforms and systems to reduce costs and to be exported. After 1973 it was revised to further reduce costs in a "telescopic development" process and the tank depot would be used as final assembly plant.

Still the program took nine years to complete, when the Merkava I was accepted for service in 1979. The 1973 war in particular, changed certain core principles, making it far more protective for its crews than more MBTs on the planet: Its powerpack was behind the nose armour, adding three meters deep extra compacted metal parts in front of the crew. It kept a low profile when in firing position and the gun depression could provide a hull-down fire position. There was no flammable materials in the crew compartment and total isolation, ammunition under the turret ring as well as hull rear in heat-resistant containers, good automated fire control system as well, and that was also original, a roof-mounted 60mm mortar to deal with infantry.

Merkava II unveiled with the ceremony for the opening of the armoured corps high school

However already in 1980, early experience led to add further modifications to the design. Whereas 250 Merkava I were built, a set of improvements was formulated. It was asked for a new, improved and better stabilized all-weather day/night fire control system. Elbit proposed this upgrade, which was accepted as the new Mark 2 Tank Fire Control System. It inrtegrated new meteorological sensors and crosswind analyser for last minute adjustments to the main gun when firing. As results of tests, there was an increase accuracy.

The sights were also upgraded: New thermal and passive night equipment were adopted, for a better resolution overall. Also, the 60mm mortar which was activated from the hatch oustide, was modified to be fired safely from within the tank. This, in partcular, reflected experience in urban Combat in Lebanon, notably sniper fire. The powerpack was not fogotten either, as the transmission was up-graded to the Ashot Ashkelon hydro mechanical automatic transmission. The latter had now four gears, a better bakance in csumption, coupled with larger fuel tanks to increase the operational range to 500km.

Other improvements were made for overall protection, starting with a new composite armour. Other than that, externally the changes looks more evolutionary than revolutionary. Despite of this, there were enough of these to justitify the new type as a Mark 2. It was accepted as standard in 1982, and produced by the same companies and suppliers until 1989 with the irst production vehicle being completed in August 1983, when production of the Mark I was officially stopped.

The Merkava Mk 2 entered production in 1982 with main improvements over the original production sucg as a layer of special armor at the front and sides of the turret, "special armor" on the hull front (composites), whereas the 60 mm Soltam Systems mortar was relocated on the left side of the turret roof to be reloaded and operated from within the turret. They had new steel skirts better protecting the suspension, backed also by "special armor".

It appeared for the first time (unveiled) in April 1983, incorporating several upgrades driven by early combat in Lebanon. Focu was on urban warfare and low-intensity conflicts.

The hull nose had a cast armored steel block and the main fuel tank was located directly behind, separated from the gearbox by a steel bulkhead. The power unit was separated by another bulkhead from the combat compartment. The latter, thanks to the absence of engine at the rear had a small exit butterfly door for the crew, protected between the rear tracks. The glacis was composed of well sloped armour panels and a complete steel firewall was located forward of the driving position, well inclined. The drivetrain was still covered by 10 mm thick steel skirts with spring-loaded attachments and the criss-crossing suspensions formed another protective layer. There was also a drinking water tank (60 liters) usable internally and externally by following troops, specific to this theater. Close to these were located the volt batteries and NBC filtration system.

To defeat mines, the chassis was backed by a V-shaped double-wall bottom. The Mark II kept the Merkava Mk. 1 fuel-filled space within the double floor with a floor valve opening outwards in case of overpressure. The Merkava II also had the same halon extinguishers (engine, combat compartment), Collective NBC protection with overpressure, full sealing, internal spall liner. The turret also had attachmement points for spare track links, and instead of smoke dischargers, mortars were used for smoke concealment, but this time internally. On the Mark II also, chains were added to the base of the turret basket to protect against RPG attack.

The cooling system had a new and more effcicient fan drive to increase the air flow by 10% since the engine was "Negev-proof", made to be used under desert conditions. It's location at the front meant it was more easily cooled but also prone to dust inhalation, the architecture of the oil cooler and exhaust were revised and filters systems easy to replace or clean up daily were fitted.

The gearbox was brand new, no longer the original Allison CD-850-6BX with torque converter, but instead the in-house Ashot Ashkelon hydromechanical automatic transmission, with 4 gears. It was fully automatic instead of semi-auto like the previous gearbox. But like the former, when used on open road, it also had a parking brake.

The Mark I drivetrain was estimated good enough to be retaken for the Merkava Mark 2. It counted the same arrangement of six rubber-tired road wheels on either side, drive sprocket at the front, idler at the rear, four track-return rollers. Each roadwheel is suspended by a separate helical spring whereas suspension arms are added for the pair of forward road wheels, caged in housing. On the Mark II that suspension system was improved for extra cross-country speeds. It is assumed to be of a pneumatic type.

Performances were increased to 64 kph instead of 46 kph on flat, at a 15,1 hp/ton power ratio. Thanks to the larger fuel tank capacity, range jumped from 400 to 500 km on flat. This was still not supremely fast for a 61 tonnes tank. The Mark II could climb a vertical Obstacle of 0.95m, performed a water crossing 1.38m (2m with preparation), 3m for a trench Crossing, and climb a 70% gradient.

Due to British embargo it was not available to the IDF in 1969 and the 105 mm was kept for greater compatibility with the M60 and Magach (M48) variants. The Mark II carried the 66 (instead of 62) shells in the hull back and under the turret raceway in a well sealed storage area like the Mark I and 6 ready rounds available to the loader for quick firing between reloads. 17 were placed in fire-resistant containers of 6 two rounds boxes and 11 containers of 4 rounds t limit shell cooking.

The IDF M64-L71A cannon like for the Mark I is the same domestic licenced M68 cannon with Vidco Ltd thermal sleeve. It is provisioned with the APDS, HEAT, HESH, Phosphorous and APFSDS ammunition for an estimated max range of 4,000 m, with a muzzle velocity 1,330 meters per second (HEAT) and rate of fire six per minute. The major difference was in the firing control (see below).

Merkava I at Saumur Museum

In additon to the 12 smoke dischargers in two banks of six, the Merkava II was given a foldable external 60 mm Soltam mortar on the right flank at the height of the tank commander for close defense, which was there reloadable from inside the turret unlike on the Mark I. It was given otherwise the same wide variety of ammunition, smoke and shrapnel, incendiary, etc.

The gunner's SLS daytime viewfinder did not changed and its associated laser rangefinder camed from the same company El-Op. The viewfinder had the same x1 to ×8 (or ×12) manifications with a reticle, commander with the same monocular periscopic sight, panoramic from IAI with two magnifications. The main sight was alternative to a passive night sight with residual light amplifier and there was still the optional 1 kW EOS Xenon headlight in a special housing on the turret rear for indirect lighting and using a reflector inclined at 45°7 to avoid direct hits.

Mk. 2C: New Appliqué modular armor on top of the slopping turret (urban threats).

Mk. 2D: New applique modular armor along the sides of the turret with big bolts, extending the length of the top of the hull, left side of the hull front and of the driver’s position.

Merkava Mk2D LIC: Small “Low intensity conflict” aka LIC package: Bll whip mounts on all corners, rear camera for the driver in urban areas, grille armour over the exhaust and vents, sights.

Saul Bronfeld, The ‘Chieftain Tank Affair’ Realpolitik, Perfidy and the Genesis of the Merkava 3 nov. 2014

Marc Chassillan, «Le Merkava», Raids Hors-Série N°3, 2001

Merkava Mk II and Mk III Israeli Main Battle Tank : Museum Ordnance Special Number 12 Paperback – 1 Jan. 1996

Sam Katz, Merkava Main Battle Tank MKs I, II & III, Osprey Publishing, May 15 1997

« Truck and Tanks magazine » on IDF, june/july 2021

Richard M. Ogorkiewicz, Technology of Tanks, Londres, Jane's Information Group, 1991

army-guide.com

fighting-vehicles.com

merkava-mk-2-tank

armyrecognition.com

M68_(tank_gun)

tanknutdave.com

primeportal.net

primeportal.net

Armored Corps starts retiring its Merkava Mark II tanks

www.israeli-weapons.com merkava generic

israeli-weapons.com Merkava Mark I

CC photos

Israeli Merkava tanks for the armed forces of ukraine truth or fiction

On scalemates

Development

Mark I in Latrun museum

Merkava 2, same, note the different exhaust, different side skirt, new pannier, rood sensors, IR searchlight, addon nose and turret armour, ect.

We are not going to retrace here all the long development of the Merkava, a project that went all the way back to the 1967 6 days war, with a serious start after the 1973 Yom Kippur war and crippling tank losses for the IDF in one engagement. Veteran general Israel Tal led the project. The project was tailored for the middle-eastern theatre of war, also planned to reuse existing platforms and systems to reduce costs and to be exported. After 1973 it was revised to further reduce costs in a "telescopic development" process and the tank depot would be used as final assembly plant.

Still the program took nine years to complete, when the Merkava I was accepted for service in 1979. The 1973 war in particular, changed certain core principles, making it far more protective for its crews than more MBTs on the planet: Its powerpack was behind the nose armour, adding three meters deep extra compacted metal parts in front of the crew. It kept a low profile when in firing position and the gun depression could provide a hull-down fire position. There was no flammable materials in the crew compartment and total isolation, ammunition under the turret ring as well as hull rear in heat-resistant containers, good automated fire control system as well, and that was also original, a roof-mounted 60mm mortar to deal with infantry.

Merkava II unveiled with the ceremony for the opening of the armoured corps high school

However already in 1980, early experience led to add further modifications to the design. Whereas 250 Merkava I were built, a set of improvements was formulated. It was asked for a new, improved and better stabilized all-weather day/night fire control system. Elbit proposed this upgrade, which was accepted as the new Mark 2 Tank Fire Control System. It inrtegrated new meteorological sensors and crosswind analyser for last minute adjustments to the main gun when firing. As results of tests, there was an increase accuracy.

The sights were also upgraded: New thermal and passive night equipment were adopted, for a better resolution overall. Also, the 60mm mortar which was activated from the hatch oustide, was modified to be fired safely from within the tank. This, in partcular, reflected experience in urban Combat in Lebanon, notably sniper fire. The powerpack was not fogotten either, as the transmission was up-graded to the Ashot Ashkelon hydro mechanical automatic transmission. The latter had now four gears, a better bakance in csumption, coupled with larger fuel tanks to increase the operational range to 500km.

Other improvements were made for overall protection, starting with a new composite armour. Other than that, externally the changes looks more evolutionary than revolutionary. Despite of this, there were enough of these to justitify the new type as a Mark 2. It was accepted as standard in 1982, and produced by the same companies and suppliers until 1989 with the irst production vehicle being completed in August 1983, when production of the Mark I was officially stopped.

Design of the Merkava mark 2

The Merkava Mk 2 entered production in 1982 with main improvements over the original production sucg as a layer of special armor at the front and sides of the turret, "special armor" on the hull front (composites), whereas the 60 mm Soltam Systems mortar was relocated on the left side of the turret roof to be reloaded and operated from within the turret. They had new steel skirts better protecting the suspension, backed also by "special armor".

It appeared for the first time (unveiled) in April 1983, incorporating several upgrades driven by early combat in Lebanon. Focu was on urban warfare and low-intensity conflicts.

Hull design

The core of the basic design was the engine placed closer to the center forward, preceded by the transmission, to keep the center of gravity balanced. Bot the turret and fighting compartment were at its rear as the ammunition storage underneath, well sheltering these, and this went with self-sealing fuel containers and a better distribution to maximize quantity.The hull nose had a cast armored steel block and the main fuel tank was located directly behind, separated from the gearbox by a steel bulkhead. The power unit was separated by another bulkhead from the combat compartment. The latter, thanks to the absence of engine at the rear had a small exit butterfly door for the crew, protected between the rear tracks. The glacis was composed of well sloped armour panels and a complete steel firewall was located forward of the driving position, well inclined. The drivetrain was still covered by 10 mm thick steel skirts with spring-loaded attachments and the criss-crossing suspensions formed another protective layer. There was also a drinking water tank (60 liters) usable internally and externally by following troops, specific to this theater. Close to these were located the volt batteries and NBC filtration system.

Armour Protection of the Merkava II

There was no fundamental change on the basic layout of the Merkava II, still with the same cast nose armour as the turret, spaced armour protection on both sides, narrow edge around the mantlet for a very small frontal surface, large base, in cast steel and large bead like on the M60A2 resting below the glacis to negate short traps. Hollow steel blocks surrounded the base cast turret and there was a double wall with extra space used as on-board storage compartments. In short, the vehicle was made of laminated armour plus "special armour". In short it had new armour plates offering the best protection available, redesigned skirts and spaced armour.To defeat mines, the chassis was backed by a V-shaped double-wall bottom. The Mark II kept the Merkava Mk. 1 fuel-filled space within the double floor with a floor valve opening outwards in case of overpressure. The Merkava II also had the same halon extinguishers (engine, combat compartment), Collective NBC protection with overpressure, full sealing, internal spall liner. The turret also had attachmement points for spare track links, and instead of smoke dischargers, mortars were used for smoke concealment, but this time internally. On the Mark II also, chains were added to the base of the turret basket to protect against RPG attack.

Powerpack and Performances of the Merkava II

The Merkava Mk 2 retained the same engine as the Mk 1 but with a new transmission and had an increased operating range of 100 km by having an increased fuel capacity. The powerpack was still the same 908 horsepower (677 kW) V12 diesel Teledyne Continental AVDS-1790-6A air cooled (power-to-weight ratio of 14 hp/Tonne). This tailed US engine for the needs of the IDF was a monster with a 29.3 l capacity, largest ever used on any Israeli combat vehicle. It developed a torque of 2,920 Nm at 2,000 rpm and compared to the AVDS-1790-2A of the M60, it was given an improved injection system, and new turbochargers to increase gas pressure inside the cylinders.The cooling system had a new and more effcicient fan drive to increase the air flow by 10% since the engine was "Negev-proof", made to be used under desert conditions. It's location at the front meant it was more easily cooled but also prone to dust inhalation, the architecture of the oil cooler and exhaust were revised and filters systems easy to replace or clean up daily were fitted.

The gearbox was brand new, no longer the original Allison CD-850-6BX with torque converter, but instead the in-house Ashot Ashkelon hydromechanical automatic transmission, with 4 gears. It was fully automatic instead of semi-auto like the previous gearbox. But like the former, when used on open road, it also had a parking brake.

The Mark I drivetrain was estimated good enough to be retaken for the Merkava Mark 2. It counted the same arrangement of six rubber-tired road wheels on either side, drive sprocket at the front, idler at the rear, four track-return rollers. Each roadwheel is suspended by a separate helical spring whereas suspension arms are added for the pair of forward road wheels, caged in housing. On the Mark II that suspension system was improved for extra cross-country speeds. It is assumed to be of a pneumatic type.

Performances were increased to 64 kph instead of 46 kph on flat, at a 15,1 hp/ton power ratio. Thanks to the larger fuel tank capacity, range jumped from 400 to 500 km on flat. This was still not supremely fast for a 61 tonnes tank. The Mark II could climb a vertical Obstacle of 0.95m, performed a water crossing 1.38m (2m with preparation), 3m for a trench Crossing, and climb a 70% gradient.

Armament

M64 L71A gun, 105 mm

The Merkava Mk2 and all its variants use the same rifled 105mm main gun as the Merkava Mk1 derived from the American M68 (M60 Patton as well as M1 Abrams), derived originally from the 1950s British L7 105mm rifled main gun. The main difference was its improved thermal sleeve compared to the Mark I, and full compatibility with US ammunitions made for the M68 and all NATO compatible one, giving a lot of flexibility. However in 1982, the new standard was already towards a 120 mm as sported by the Chieftain.Due to British embargo it was not available to the IDF in 1969 and the 105 mm was kept for greater compatibility with the M60 and Magach (M48) variants. The Mark II carried the 66 (instead of 62) shells in the hull back and under the turret raceway in a well sealed storage area like the Mark I and 6 ready rounds available to the loader for quick firing between reloads. 17 were placed in fire-resistant containers of 6 two rounds boxes and 11 containers of 4 rounds t limit shell cooking.

The IDF M64-L71A cannon like for the Mark I is the same domestic licenced M68 cannon with Vidco Ltd thermal sleeve. It is provisioned with the APDS, HEAT, HESH, Phosphorous and APFSDS ammunition for an estimated max range of 4,000 m, with a muzzle velocity 1,330 meters per second (HEAT) and rate of fire six per minute. The major difference was in the firing control (see below).

Secondaries:

The secondary armament was composed of two 7.62 mm machine guns, one coaxial the other roof-mounted close to the Commander's cupola. A third M2HB Browning 0.5 cal or 12.7 mm could be pintle-mounted on the roof optionally. This scheme was retained for the Mark II.Mortar:

Merkava I at Saumur Museum

In additon to the 12 smoke dischargers in two banks of six, the Merkava II was given a foldable external 60 mm Soltam mortar on the right flank at the height of the tank commander for close defense, which was there reloadable from inside the turret unlike on the Mark I. It was given otherwise the same wide variety of ammunition, smoke and shrapnel, incendiary, etc.

Fire Control

The fire control system designed in Israel was competely renewed and modernized. Called the Matador Mk 2, it included a YAG laser range-finder in place of the original Neodymium-glass laser range-finder and more advanced ballistic computer. Data quality was also improved thanks to more modern meteorological sensors, with new crosswind analyzers, thermographic optics, image intensifiers for better battlefield awareness.The gunner's SLS daytime viewfinder did not changed and its associated laser rangefinder camed from the same company El-Op. The viewfinder had the same x1 to ×8 (or ×12) manifications with a reticle, commander with the same monocular periscopic sight, panoramic from IAI with two magnifications. The main sight was alternative to a passive night sight with residual light amplifier and there was still the optional 1 kW EOS Xenon headlight in a special housing on the turret rear for indirect lighting and using a reflector inclined at 45°7 to avoid direct hits.

Merkava Mark II specifications 1982 | |

| Dimensions (l-w-h): | 8.63oa (7.45) x 3.7 x 2.64 m |

| Total weight, battle ready: | 61 t |

| Crew : | 4 men: Commander, Driver, gunner, loader |

| Propulsion: | AVDS 1790-6A V12 diesel 908 hp |

| Transmission: | Ashot Ashkelon hydromechanical automatic |

| Suspensions: | Torsion bars, Hydrosprings |

| Top Speed | 46 km/h |

| Range (road) | 500 km, 1400 L fuel |

| Armament (see notes) | 105 mm rifled (62), 3 x 7.62 mm (10k rds) |

| Armour | See notes: Laminated RHA plus special armour (still classified) |

| Total Production | 580 |

Variants

Mk. 2B: Improved thermal optics, unspecified updates to the fire control system.Mk. 2C: New Appliqué modular armor on top of the slopping turret (urban threats).

Mk. 2D: New applique modular armor along the sides of the turret with big bolts, extending the length of the top of the hull, left side of the hull front and of the driver’s position.

Merkava Mk2D LIC: Small “Low intensity conflict” aka LIC package: Bll whip mounts on all corners, rear camera for the driver in urban areas, grille armour over the exhaust and vents, sights.

The Merkava 2 in action

To come in a future update, if available.Links/src

Saul Bronfeld, The ‘Chieftain Tank Affair’ Realpolitik, Perfidy and the Genesis of the Merkava 3 nov. 2014

Marc Chassillan, «Le Merkava», Raids Hors-Série N°3, 2001

Merkava Mk II and Mk III Israeli Main Battle Tank : Museum Ordnance Special Number 12 Paperback – 1 Jan. 1996

Sam Katz, Merkava Main Battle Tank MKs I, II & III, Osprey Publishing, May 15 1997

« Truck and Tanks magazine » on IDF, june/july 2021

Richard M. Ogorkiewicz, Technology of Tanks, Londres, Jane's Information Group, 1991

army-guide.com

fighting-vehicles.com

merkava-mk-2-tank

armyrecognition.com

M68_(tank_gun)

tanknutdave.com

primeportal.net

primeportal.net

Armored Corps starts retiring its Merkava Mark II tanks

www.israeli-weapons.com merkava generic

israeli-weapons.com Merkava Mark I

CC photos

Israeli Merkava tanks for the armed forces of ukraine truth or fiction

On scalemates

A Merkava Mk.2 during the Lebanon War, 1984. The olive green livery was customary for armored units operating in the north of the country and along the Syrian border, and sand beige for southern units.

Mark 2b

Mark 2b (also in desert colors)

Mark 2D

More to come if references are found: Mark 2c, Mark 2D LIC.

Beaufort tank south lebanon 1995

Merkava 2 of the Armored Corps Operating Near the Gaza Border

Merkava 2D, IDF 7th Brigade in exercises March 2009

Merkava Mk.II in the Golan Heights, 1987

Golani Brigade large scale exercise

Merkava 2 at Shamis al urqub near Aaichiye sounth lebanon, 1997

Merkava 2 435 Bat.

Golani Battalion in Manoeuvers, Goland height Merkava II

3D rendition

Mark II Golan 1986

model kit

Mark II with mine roller

Tank ride (pinterest)

boxart rendition, Mark 2D (training tank)

Merkava Video

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com

Tsahal

Tsahal