The Merkava Main Battle Tank is today one of the most singular, notably because it did not came from traditional actors/manufacturers of the type, located mostly in the northern hemisphere. This was the first designed and built in the Middle east, but also with a range of unique features, pretty unique in that restricted club. The Merkava ("chariot") was first designed in the early 1970s, right after, and taking lessons from, the 1973 Yom Kippur war, under General Israel Tal. This flagship of the IDF has some influences but became unique in design choices, which proved worthwile as the type is still in service today after half a century, 45 years of service with the latest Mark IV Barak, and replacement in sight, with the Carmel developed from 2012 by IAI, and still ongoing.

The story of the Merkava is as long as IDF warfare, practically right from the creation of the country, exposed to Arab attacks. In the 1948 war, IDF started with a motley collection of 15 tanks, whereas the Arabs had 45. In the Sinai campaign in 1956, 200 tanks were deployed, and again, lessons were taken from the use of many types, from Modified Shermans to AMX-13s, with mostly Soviet-equipped opponents. In the 1967 6-days war, the IDF deployed some 2500 tanks, 6200 engaged by contesting sides, seeing the largest tanks battles since WW2.

The bulk of the IDF at the time comprised refurbished "Isherman", ww2 half-tracks and a bunch of British Centurions and American M48s locally named Magach whereas the former were later modified as the Sho't.

Nevertheless arms embargoes soon pushed the IDF to improvized solution, upgrading endlessely its park, whereas captured T-54/55s were either modernized or recycled as heavy APCs. All these experiences were duly reported, generating statistics and creating a corpus worthy of future requirements, for either a domestic tank, or foreign model provided the ban was lifted.

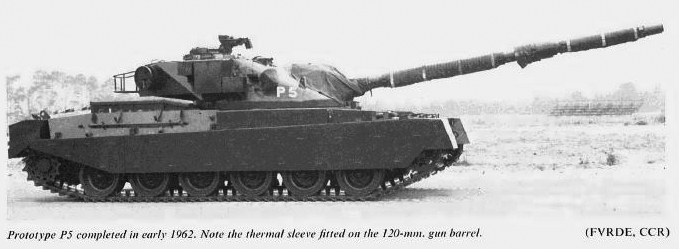

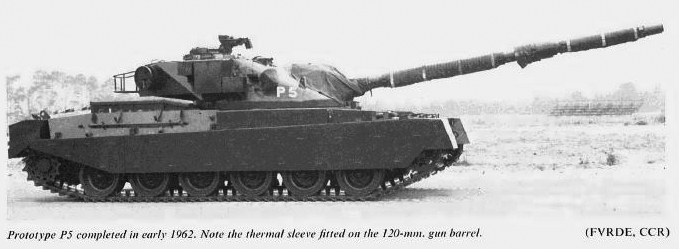

Chieftain P5 prototype in 1962 (British Leyland).

Already in 1964-65, when Arab contries obtained the T-62 (armed with a 125 mm smoothbore), the IDF had nothing to compare, with its aging park mostly out-gunned. Aware of this, British authorities proposed Israel to participate to the elaboration of a model that can suit its interests as much as Britain or NATO, developed specifically to answer the T-62 with a 120 mm rifled gun. So by 1966, Britain, budget-strapped, proposed to Israel a participation in the program under a "package deal" i which IDF would acquired a large park of now retired Centurion tanks and finance, but also participate in the last stages of Chieftain Main Battle Tank development and developed an assembly line in Israel for these.

But the cooperation, which ran strong for three years and culminating with two prototypes delivered to Israel, evaluated at Tsahal tank corps trials Nahal Tzin. But this was all butally stopped as the OPEP promised massive sanctions, actions compounded by actions against British embassies. The deal was eventually cancelled by November 1969 and the Chieftain was completed by UK alone (or sold to potential adversaries such as Jordan).

Nevertheless, for what it was worth, this narrow collaboration with British engineers, some taking residence in Israel generated a mass of documentation, in which the IDF could pull out a domestic design, provided the procurement of non-British parts were found, quite a tricky proposal between the 120 mm gun, which needed years in development, and engine, or even the highly classified, composite Chobham armour package, reputed at the time the best in the world. Many considered these three years had been largely wasted. There was the remaining ten thousands million mark question: Was Israel could develop and manufacture a homemade tank in the frame of the country's economical situation?

Merkava Prototype, 1977

To the more elaborate set of questions asked to the government and experts by Major General israel Tal, Reports and statistics prepared for the executive to discuss and decide, ended mostly positive. In 1970, British, France or the US all continued to ban exports. So Israel, a small and recent country, made the monumental decision to develop its own Main battle Tank. One financial incentive, was that the sythesis of solutions retained for its design will make it attractive for export as well, and somewhat recoup the immense developement costs. After all, britain seemingly was not able to finance alone the entire Chieftain program back in 1966...

If the core principle behind the design was that the model had a set of specifications tailored for the middle-eastern theatre of war, the initial program also planned to reuse existing platforms and systems to reduce costs. However as the program evolved in 1971-72 it appeared soon clearly that the amount of constraints born from these hampered the final program to the point of compromising its reach of the original specifications.

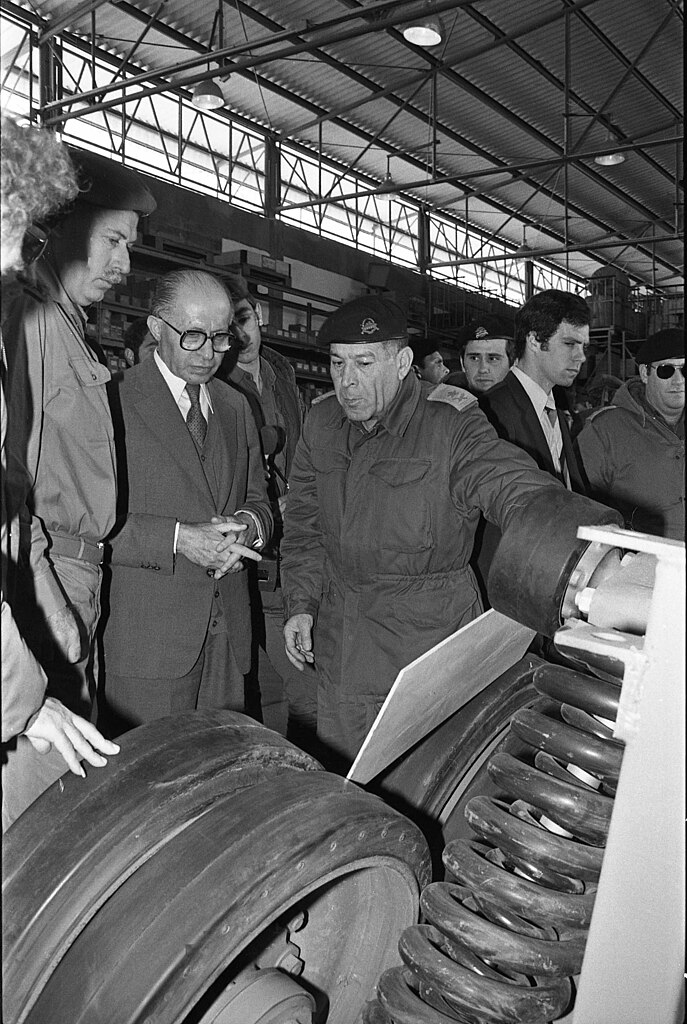

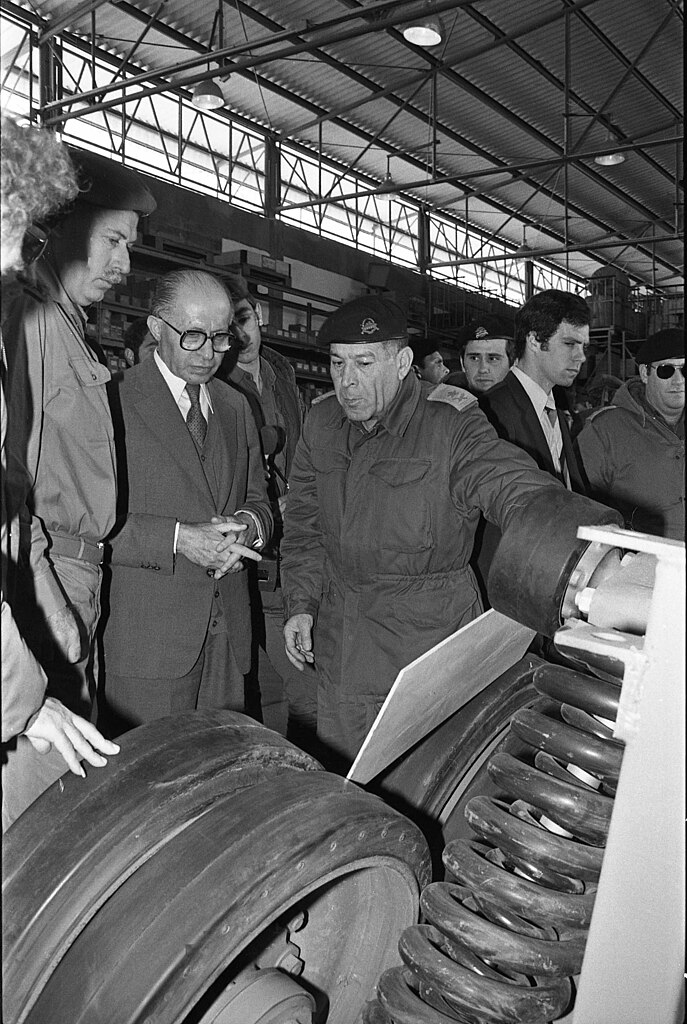

PM Menachem Begin and Gen. Tal visiting the Taas Industry Complex, where the Merkava Tanks are produced

And since Israel needed these tanks fast, it was decided to shorten development time under the risky but quick "telescopic development" process. According to this, the first model would lead to a serial production based on prototypes, before even completion of a the development and prior to the finalize production files. In general a tank reached production after a long cycle from the drawing board to full official acceptation, which started only after all the phases of tests and modifications ended.

To continue keeping the costs low (and also gain time), the Project Administration wouldnot require a new infrastructure and personal, but would restrain itself to already existing MOD/IDF infrastructures. It was decided to gain full collaboration at all echelons regardless of their usual tasks, and cut down/shortcut all intermediaries and/or potential bureaucratic bottlenecks. In the end, the IDF basic tank depot would be used as final assembly plant. Still it soon appeared necessary to upgrade and modernize many industrial plants, which included acquisition abroad of machine-tools that were not under any ban.

The master idea was to use whenever possible components already proven or mastered by national players and major technological breakthrough envisaged. To also plugin the whole program, it was decided to acquire missing knowledge from abroad when practicable, and otherwise self-developed by a very intensive trials program all along. Nevertheless, for such an enterprise, from scratch (The IDF would do the same when creating the fighter IAI LAVI) it took nine year until the Merkava I became operational, from decision to service acceptance (1970-79).

Intrumental figure behind the program albeit resting on several thousands of contributing engineers, designers and specialists throughout the country, Tal was born in 1925's Mahanayim in Mandatory Palestine from a Hassidic Jews family that migrated to Safed, and experienced the 1929 Palestine riots. long story short, he made his military service at 17 with the British Army's Jewish Brigade in WW2 (North Africa, Italy campaign).

In 1946, he enlisted in the newly formed Haganah and became junior infantry officer in the 1947–1949 Palestine war, brigade commander in 1956, armored-division commander in the 6-Day War, and southern front commander in the Yom Kippur War. In the latter he created the Israeli armored doctrine leading to the victory at the Sinai. He milited for high mobility and relentless assault, long range gunnery proficiency (beyond the 1.5 km mark), capitalizing in the poor quality of Soviet Tanks' optics in Arab service, restricted both in elevation and to 200-500 m accuracy.

First public appearance of the Merkava, in a stadium in Jerusalem on May 14, 1978, next to a Cromwell to celebrate the 30th anniversary of the declaration of independence of the State of Israel.

Well regarded by its peers due to its experience with tank companies, brigades, regiments, divisions and corps, and corpus of doctrines, influencial domestically and abroad, proactive, he was naturally chosen in 1970 to lead a development team behind the Merkava program. In 1997, Tal was awarded the Israel Prize for his contribution to the society and State of Israel, and is regarded locally as on par with Creighton Abrams, Patton and Rommel.

One of the base principle was to considered an experienced, well trained tank crew was an immensely valuable asset, and the carrier secondary or "expandable", just a tool that can be replaced. It should be placed in the Israeli context of the time, with a limited population of 3 million, in a country surrounded by far more numerous, and mainly hostile arab populations. Even if hit, the tank should give the best chances of survival to its crew. It led notably to its most impressive and distinctive feature, placing the engine at the front, as extra protection. But also the evacuation at the rear like an APC, almost between tracks. Although the MTU engine chosen was pretty common at the time, this layout was unique and remains so to this day.

The nose had a cast armored steel block behind which was located the fuel tank, separated from the gearbox by a steel bulkhead. The power unit followed, a bulkhead, and then the combat compartment with an exit hatch behind. The glacis is made of sloped armour panels, and separated from the combat compartment by a steel firewall, at the front of the driving position, the latter is inclined. The body offsets above the tracks, containing fuel tanks as well as the air intakes and stowage bins. The drivetrain was covered by 10 mm thick steel skirts fixed by spring-loaded attachments. The thick criss-crossing suspensions also further protects the chassis.

The back plate contains a butterfly door (opening up and down) for access to and evacuation of the combat compartment, and allow ammunition load. Above it a drinking water tank with a capacity of 60 liters accessible internally but also externally to accompanying troops. On either side two armored compartments contains, for the left one, six 12 volt batteries, and right one, the NBC filtration system.

Rear plate, access door.

The vehicle had a cast nose armour (as the turret), and spaced armour protection was added on both sides side, with armoured equipment compartments, flexible fuel tanks (self-sealing, aviation grade) to avoid rupturing issues.

The turret has the same profile used for the Chieftain, with a narrow edge like nose, around the mantlet, giving as little frontal surface as possible. It has a narrow profile but large base, generally small compared to the chassis, well profiled. It is composed of a larger round cast steel base as a large bead like on the M60A2 and resting slightly below the glacis to avoid the usual short trap here.

The frontal armor is made up of hollow steel blocks fixed to the structure of the turret and the sides comprised a double wall, with extra space used as on-board storage compartments. The rear houses two compartments, right rear housing the turret's main hydraulic systems and in the left, two 12-volt batteries and xenon headlight. See from the profile the turret is shaped as a double wedge, really unique.

Protection against mines was paid attention with a double-wall bottom in shape of a flattened V, also capable against IEDs. On the Merkava Mk. 1, the space within this double floor is filled with fuel, playing a role in deflecting the blast inwards. There was a floor valve opening outwards in case of hit overpressure, to jettison rapidly all fuel and preventing internal spilling in the crew compartment. The tank is also equipped with the usual halon extinguishers in the engine and combat compartment. As said above it is also NBC protected (collective) with overpressure and full sealing. There is also the usual internal spall liner. However if additional attachmement points allowed to store spare track links on the turret as addon protection, there are no smoke dischargers, the mortar is used instead for smoke concealment.

The cooling system was also stronger, with a new, more effcicient fan drive, increasing the air flow by 10%. The engine designed for the Merkava was also modified to operate in the Negev desert if needed and the fact the engine compartment was located at the front made it more easily cooled when in motion, but the architecture of the oil cooler and exhaust were revised.

The Allison CD-850-6BX gearbox, automatic, used a torque converter, with two gears available forward, one in reverse at all times. Gear selection was manually, with a gear lever. The steering used triple differential and braking used disc brakes. When used on open road it also had a parking brake. The 60tonnes tanj was able to negociate a Gradient of 60%, stay stable on a 40% side slope, climb a Vertical step one one meter, gap a three meters trench or ford a 1.4 m deep river.

Based on this, the undercarriage, was inspired by components from the Centurion like track rollers, T-55 track screw tensioning system and M48 carrying rollers or even the Chieftain's spring suspension elements. The latter could be more esily dismounted and replaced in the field. Each track roller is attached to a suspension arm and to its own coil spring. They came in pairs on each suspension element, six total, three per side, for two roadwheels each. These were simple to manufacture and could be easily replaced in the field, notably after a mine explosion. Vertical travel varied between roller position with a nominal 210 mm in compression and between 85 mm and 170 mm in extension, for a total of 295 mm to 380 mm. Thus drivetrain was estimated good enough to be retaken for the Merkava Mark 2.

Performances are as follows: 46 kph top speed on flat, which was average at the time, but comparable to the Chieftain, for a 14 to 15,1 hp/ton power ratio. Thanks to a 900 liter tank, range was 400 km, again, on flat. On the heavier Mark 4 a MTU V12 TurboDiesel GD883 was adopted. It is made under licence by L-3 Communication Combat Propulsion Systems (formerly General Dynamics) located in Muskegon, Michigan. This shows the upgrade in two decades.

The M64-L71A cannon was a domestic production, licenced version of the US M68 cannon, itself derived from the British L7. The barrel tube receive a thermal sleeve designed by Vidco Ltd also in Israel. The 105mm ammunition is thus not stored in but under the turret raceway, in a position difficult to reach for an incoming hit. Six ready rounds however are avilable next to the loader, fifty-six in the rear compartment in 17 fire-resistant containers of six containing two rounds, eleven contain four each. This heavy compartimentation ensures a shell cooking would be limited in effect.

Performances of the L71A, which could fire APDS, HEAT, HESH, Phosphorous and APFSDS ammunition are as follows: Range estimated 4,000 m, muzzle velocity 1,330 meters per second again depending on the round used, rate of fire six per minute.

Merkava I at Saumur Museum

Instead of the usual smoke discharger banks, the Merkava I was given a foldable external 60 mm Soltam mortar on the right flank at the height of the tank commander for close defense. It could be reloaded from inside, with a wide variety of ammunition, smoke and shrapnel, incendiary, etc.

The gunner's SLS daytime viewfinder was composed of a Nd-YAG laser rangefinder from El-Op. The viewfinder had a x1 to ×8 (or ×12) manifications and the reticle was controlled by a US-provided M13A1 digital ballistic computer made under licenced in Israel by Oranit.

The commander had a monocular periscopic sight for target detection. It was panoramic and manufactured by Israel Aircraft Industries (IAI) with two magnifications: × 4 and × 20. It was very close to the German Leopard's TRP-2A viewfinder (reputed the world's best). The main sight could be swapped for a passive night sight, with a residual light amplifier. It could be enhanced by a 1 kW EOS Xenon headlight placed vertically in a special housing at the left rear of the turret, behind the loader hatch, using indirect lighting under retractable plastic reflector inclined at 45°7 to avoid direct hits.

Mk. 1B (Siman 1 Bet): Mark I Hybrid, tested with the tracks and chain turret trap protection from Merkava Mk. 2.

Sholef: Prototype self propelled howitzer made in 1984, and 1986. Projet abandoned 1997.

Namera: Prototype heavy armored personnel carrier, from surplus Merkava Mk.1 chassis (2005)

Marc Chassillan, «Le Merkava», Raids Hors-Série N°3, 2001

Sam Katz, Merkava Main Battle Tank MKs I, II & III, Osprey Publishing, May 15 1997

« Truck and Tanks magazine » on IDF, june/july 2021

Richard M. Ogorkiewicz, Technology of Tanks, Londres, Jane's Information Group, 1991

fighting-vehicles.com

militarytoday.com

M68_(tank_gun)

tanknutdave.com

armor-il.blogspot.com

www.israeli-weapons.com merkava generic

israeli-weapons.com Merkava Mark I

Israeli Merkava tanks for the armed forces of ukraine truth or fiction

A long development (1966-1979)

The story of the Merkava is as long as IDF warfare, practically right from the creation of the country, exposed to Arab attacks. In the 1948 war, IDF started with a motley collection of 15 tanks, whereas the Arabs had 45. In the Sinai campaign in 1956, 200 tanks were deployed, and again, lessons were taken from the use of many types, from Modified Shermans to AMX-13s, with mostly Soviet-equipped opponents. In the 1967 6-days war, the IDF deployed some 2500 tanks, 6200 engaged by contesting sides, seeing the largest tanks battles since WW2.

The bulk of the IDF at the time comprised refurbished "Isherman", ww2 half-tracks and a bunch of British Centurions and American M48s locally named Magach whereas the former were later modified as the Sho't.

Nevertheless arms embargoes soon pushed the IDF to improvized solution, upgrading endlessely its park, whereas captured T-54/55s were either modernized or recycled as heavy APCs. All these experiences were duly reported, generating statistics and creating a corpus worthy of future requirements, for either a domestic tank, or foreign model provided the ban was lifted.

The 1966-69 Chieftain Deal

Chieftain P5 prototype in 1962 (British Leyland).

Already in 1964-65, when Arab contries obtained the T-62 (armed with a 125 mm smoothbore), the IDF had nothing to compare, with its aging park mostly out-gunned. Aware of this, British authorities proposed Israel to participate to the elaboration of a model that can suit its interests as much as Britain or NATO, developed specifically to answer the T-62 with a 120 mm rifled gun. So by 1966, Britain, budget-strapped, proposed to Israel a participation in the program under a "package deal" i which IDF would acquired a large park of now retired Centurion tanks and finance, but also participate in the last stages of Chieftain Main Battle Tank development and developed an assembly line in Israel for these.

But the cooperation, which ran strong for three years and culminating with two prototypes delivered to Israel, evaluated at Tsahal tank corps trials Nahal Tzin. But this was all butally stopped as the OPEP promised massive sanctions, actions compounded by actions against British embassies. The deal was eventually cancelled by November 1969 and the Chieftain was completed by UK alone (or sold to potential adversaries such as Jordan).

Nevertheless, for what it was worth, this narrow collaboration with British engineers, some taking residence in Israel generated a mass of documentation, in which the IDF could pull out a domestic design, provided the procurement of non-British parts were found, quite a tricky proposal between the 120 mm gun, which needed years in development, and engine, or even the highly classified, composite Chobham armour package, reputed at the time the best in the world. Many considered these three years had been largely wasted. There was the remaining ten thousands million mark question: Was Israel could develop and manufacture a homemade tank in the frame of the country's economical situation?

Development under M.G. Israel Tal (1970-79)

Merkava Prototype, 1977

To the more elaborate set of questions asked to the government and experts by Major General israel Tal, Reports and statistics prepared for the executive to discuss and decide, ended mostly positive. In 1970, British, France or the US all continued to ban exports. So Israel, a small and recent country, made the monumental decision to develop its own Main battle Tank. One financial incentive, was that the sythesis of solutions retained for its design will make it attractive for export as well, and somewhat recoup the immense developement costs. After all, britain seemingly was not able to finance alone the entire Chieftain program back in 1966...

If the core principle behind the design was that the model had a set of specifications tailored for the middle-eastern theatre of war, the initial program also planned to reuse existing platforms and systems to reduce costs. However as the program evolved in 1971-72 it appeared soon clearly that the amount of constraints born from these hampered the final program to the point of compromising its reach of the original specifications.

PM Menachem Begin and Gen. Tal visiting the Taas Industry Complex, where the Merkava Tanks are produced

And since Israel needed these tanks fast, it was decided to shorten development time under the risky but quick "telescopic development" process. According to this, the first model would lead to a serial production based on prototypes, before even completion of a the development and prior to the finalize production files. In general a tank reached production after a long cycle from the drawing board to full official acceptation, which started only after all the phases of tests and modifications ended.

To continue keeping the costs low (and also gain time), the Project Administration wouldnot require a new infrastructure and personal, but would restrain itself to already existing MOD/IDF infrastructures. It was decided to gain full collaboration at all echelons regardless of their usual tasks, and cut down/shortcut all intermediaries and/or potential bureaucratic bottlenecks. In the end, the IDF basic tank depot would be used as final assembly plant. Still it soon appeared necessary to upgrade and modernize many industrial plants, which included acquisition abroad of machine-tools that were not under any ban.

The master idea was to use whenever possible components already proven or mastered by national players and major technological breakthrough envisaged. To also plugin the whole program, it was decided to acquire missing knowledge from abroad when practicable, and otherwise self-developed by a very intensive trials program all along. Nevertheless, for such an enterprise, from scratch (The IDF would do the same when creating the fighter IAI LAVI) it took nine year until the Merkava I became operational, from decision to service acceptance (1970-79).

Industrial Montage, supply chain

The Israeli Ordnance and Ammunition Service that took the head of the program under Marj. Gen. Tal had the know-how in the field of tank modernization, by mondernizing M48s and Centurions in Israel with components of the M60 such as the AVDS-1790-2 diesel engine, CD-850 gearbox, M68 cannon and M13A1 analog fire control. Overall the actors concerned would be:- IMI: 105 mm and ammunition

- TGL SP Industries LTD: Road wheels

- Urdan Industries: hull, drive, powertrains, turret assemblies

- Soltam: 60 mm internal mortar

- Elta: Electronic sensors, IR optics

- Elbit: Ballistics computer, FCS, electric turret/gun controls

- Tadiran: Air conditioning, crew cabin intercom, radio equipment

- El-Op/Elisra/Astronautics implement: Optics. Later: laser warning systems

- Motorola: Tadiran communication encryption system

- DuPont: Nomex fire-retardant material

- FN Herstal: 7.62 mm MAG 58 and 12.7 mm M2

- Caterpillar: Assistance for the Israeli-designed track system

A word on Israel Tal

Intrumental figure behind the program albeit resting on several thousands of contributing engineers, designers and specialists throughout the country, Tal was born in 1925's Mahanayim in Mandatory Palestine from a Hassidic Jews family that migrated to Safed, and experienced the 1929 Palestine riots. long story short, he made his military service at 17 with the British Army's Jewish Brigade in WW2 (North Africa, Italy campaign).

In 1946, he enlisted in the newly formed Haganah and became junior infantry officer in the 1947–1949 Palestine war, brigade commander in 1956, armored-division commander in the 6-Day War, and southern front commander in the Yom Kippur War. In the latter he created the Israeli armored doctrine leading to the victory at the Sinai. He milited for high mobility and relentless assault, long range gunnery proficiency (beyond the 1.5 km mark), capitalizing in the poor quality of Soviet Tanks' optics in Arab service, restricted both in elevation and to 200-500 m accuracy.

First public appearance of the Merkava, in a stadium in Jerusalem on May 14, 1978, next to a Cromwell to celebrate the 30th anniversary of the declaration of independence of the State of Israel.

Well regarded by its peers due to its experience with tank companies, brigades, regiments, divisions and corps, and corpus of doctrines, influencial domestically and abroad, proactive, he was naturally chosen in 1970 to lead a development team behind the Merkava program. In 1997, Tal was awarded the Israel Prize for his contribution to the society and State of Israel, and is regarded locally as on par with Creighton Abrams, Patton and Rommel.

Merkava Design: Survivability at the core

The main principle director behind the Merkava (the name means "chariot" and recalled the elites of Solomon's armies) was the survival of its crew, through battle experience. This design pushed the envelope of protection not only well above Soviet tanks of the time, including the T-62, some of which were captured, but even above contemporary Western MBTs.One of the base principle was to considered an experienced, well trained tank crew was an immensely valuable asset, and the carrier secondary or "expandable", just a tool that can be replaced. It should be placed in the Israeli context of the time, with a limited population of 3 million, in a country surrounded by far more numerous, and mainly hostile arab populations. Even if hit, the tank should give the best chances of survival to its crew. It led notably to its most impressive and distinctive feature, placing the engine at the front, as extra protection. But also the evacuation at the rear like an APC, almost between tracks. Although the MTU engine chosen was pretty common at the time, this layout was unique and remains so to this day.

Base principles

They can be summup that way:- Powerpack behind nose armour, adding 3 m of compact metal parts in front of the crew

- Low profile when in firing position, helped by the good gun depression and suspension

- No flammable materials in the crew compartments, total isolation

- Main gun ammunition under turret ring, hull rear in heat-resistant containers

- Improved mobility, fire control system, composite armor*

- Internal 60mm mortar to deal with infantry*

Hull design

Due to the main desing choice, the engine is not "at the front" but rather, like in modern sportscars, placed closer to the center, to keep the center of gravity balanced. The turret and fighting compartment were placed at its rear, then the ammunition storage, literrally the most critical piece of equipment. And this included self-sealing fuel containers.The nose had a cast armored steel block behind which was located the fuel tank, separated from the gearbox by a steel bulkhead. The power unit followed, a bulkhead, and then the combat compartment with an exit hatch behind. The glacis is made of sloped armour panels, and separated from the combat compartment by a steel firewall, at the front of the driving position, the latter is inclined. The body offsets above the tracks, containing fuel tanks as well as the air intakes and stowage bins. The drivetrain was covered by 10 mm thick steel skirts fixed by spring-loaded attachments. The thick criss-crossing suspensions also further protects the chassis.

The back plate contains a butterfly door (opening up and down) for access to and evacuation of the combat compartment, and allow ammunition load. Above it a drinking water tank with a capacity of 60 liters accessible internally but also externally to accompanying troops. On either side two armored compartments contains, for the left one, six 12 volt batteries, and right one, the NBC filtration system.

Armour Protection

Rear plate, access door.

The vehicle had a cast nose armour (as the turret), and spaced armour protection was added on both sides side, with armoured equipment compartments, flexible fuel tanks (self-sealing, aviation grade) to avoid rupturing issues.

The turret has the same profile used for the Chieftain, with a narrow edge like nose, around the mantlet, giving as little frontal surface as possible. It has a narrow profile but large base, generally small compared to the chassis, well profiled. It is composed of a larger round cast steel base as a large bead like on the M60A2 and resting slightly below the glacis to avoid the usual short trap here.

The frontal armor is made up of hollow steel blocks fixed to the structure of the turret and the sides comprised a double wall, with extra space used as on-board storage compartments. The rear houses two compartments, right rear housing the turret's main hydraulic systems and in the left, two 12-volt batteries and xenon headlight. See from the profile the turret is shaped as a double wedge, really unique.

Protection against mines was paid attention with a double-wall bottom in shape of a flattened V, also capable against IEDs. On the Merkava Mk. 1, the space within this double floor is filled with fuel, playing a role in deflecting the blast inwards. There was a floor valve opening outwards in case of hit overpressure, to jettison rapidly all fuel and preventing internal spilling in the crew compartment. The tank is also equipped with the usual halon extinguishers in the engine and combat compartment. As said above it is also NBC protected (collective) with overpressure and full sealing. There is also the usual internal spall liner. However if additional attachmement points allowed to store spare track links on the turret as addon protection, there are no smoke dischargers, the mortar is used instead for smoke concealment.

Powerpack and Performances

The Mark I was fitted with a 908 horsepower (677 kW) V12 diesel Teledyne Continental AVDS-1790-6A air cooled, with a power-to-weight ratio of 14 hp/Tonne. The AVDS-1790-6A was a supercharged displacing 29.3 l. and the largest engine ever used on the IDF tank park. It develops a nominal power of 908 horsepower at 2,400 rpm, with a a torque of 2,920 Nm at 2,000 rpm. Very close to the AVDS-1790-2A used on the M60, it had an improved injection system, with a supercharging unit provided new turbochargers to increase gas pressure inside cylinders.The cooling system was also stronger, with a new, more effcicient fan drive, increasing the air flow by 10%. The engine designed for the Merkava was also modified to operate in the Negev desert if needed and the fact the engine compartment was located at the front made it more easily cooled when in motion, but the architecture of the oil cooler and exhaust were revised.

The Allison CD-850-6BX gearbox, automatic, used a torque converter, with two gears available forward, one in reverse at all times. Gear selection was manually, with a gear lever. The steering used triple differential and braking used disc brakes. When used on open road it also had a parking brake. The 60tonnes tanj was able to negociate a Gradient of 60%, stay stable on a 40% side slope, climb a Vertical step one one meter, gap a three meters trench or ford a 1.4 m deep river.

Based on this, the undercarriage, was inspired by components from the Centurion like track rollers, T-55 track screw tensioning system and M48 carrying rollers or even the Chieftain's spring suspension elements. The latter could be more esily dismounted and replaced in the field. Each track roller is attached to a suspension arm and to its own coil spring. They came in pairs on each suspension element, six total, three per side, for two roadwheels each. These were simple to manufacture and could be easily replaced in the field, notably after a mine explosion. Vertical travel varied between roller position with a nominal 210 mm in compression and between 85 mm and 170 mm in extension, for a total of 295 mm to 380 mm. Thus drivetrain was estimated good enough to be retaken for the Merkava Mark 2.

Performances are as follows: 46 kph top speed on flat, which was average at the time, but comparable to the Chieftain, for a 14 to 15,1 hp/ton power ratio. Thanks to a 900 liter tank, range was 400 km, again, on flat. On the heavier Mark 4 a MTU V12 TurboDiesel GD883 was adopted. It is made under licence by L-3 Communication Combat Propulsion Systems (formerly General Dynamics) located in Muskegon, Michigan. This shows the upgrade in two decades.

Armament

M64 L71A gun, 105 mm

Compared to the Chieftain, not accessible to the IDF in 1969, and its coveted 120 mm gun, Israel had to back down for its domestic tank on a better known and available M69 tank gun, already used on the M60 and updated M48 (Magach) variants. 62 shells were stored in the hull back well sealed storage area. The tank had some ready rounds though, and the job of the loader was to ensure quick delivery between combat uses.The M64-L71A cannon was a domestic production, licenced version of the US M68 cannon, itself derived from the British L7. The barrel tube receive a thermal sleeve designed by Vidco Ltd also in Israel. The 105mm ammunition is thus not stored in but under the turret raceway, in a position difficult to reach for an incoming hit. Six ready rounds however are avilable next to the loader, fifty-six in the rear compartment in 17 fire-resistant containers of six containing two rounds, eleven contain four each. This heavy compartimentation ensures a shell cooking would be limited in effect.

Performances of the L71A, which could fire APDS, HEAT, HESH, Phosphorous and APFSDS ammunition are as follows: Range estimated 4,000 m, muzzle velocity 1,330 meters per second again depending on the round used, rate of fire six per minute.

Secondaries:

The secondary armament was composed of two 7.62 mm machine guns, one coaxial the other roof-mounted close to the Commander's cupola. A third M2HB Browning 0.5 cal or 12.7 mm could be pintle-mounted on the roof optionally.Mortar:

Merkava I at Saumur Museum

Instead of the usual smoke discharger banks, the Merkava I was given a foldable external 60 mm Soltam mortar on the right flank at the height of the tank commander for close defense. It could be reloaded from inside, with a wide variety of ammunition, smoke and shrapnel, incendiary, etc.

Fire Control

The fire control system designed in Israel comprised sights, a L\P sight for the gunner and a commander's panoramic set of periscopes. There was a ballistic computer as well as a ballistic drive and azimuth indicator, with elevation quadrant. A searchlight was positioned close to the commanders hatch.The gunner's SLS daytime viewfinder was composed of a Nd-YAG laser rangefinder from El-Op. The viewfinder had a x1 to ×8 (or ×12) manifications and the reticle was controlled by a US-provided M13A1 digital ballistic computer made under licenced in Israel by Oranit.

The commander had a monocular periscopic sight for target detection. It was panoramic and manufactured by Israel Aircraft Industries (IAI) with two magnifications: × 4 and × 20. It was very close to the German Leopard's TRP-2A viewfinder (reputed the world's best). The main sight could be swapped for a passive night sight, with a residual light amplifier. It could be enhanced by a 1 kW EOS Xenon headlight placed vertically in a special housing at the left rear of the turret, behind the loader hatch, using indirect lighting under retractable plastic reflector inclined at 45°7 to avoid direct hits.

Merkava Mark I specifications 1979 | |

| Dimensions (l-w-h): | 8.63oa (7.45) x 3.7 x 2.64 m |

| Total weight, battle ready: | 60 t |

| Crew : | 4 men: Commander, Driver, gunner, loader |

| Propulsion: | AVDS 1790-6A diesel 908 hp |

| Suspensions: | |

| Top Speed | 46 km/h |

| Range (road)/Fuel consumption | 400 km |

| Armament (see notes) | 105 mm rifled (62), 3 x 7.62 mm (10k rds) |

| Armour | See notes |

| Total Production | 250 |

Variants

Mk. 1: Original Merkava Mark 1 production modelMk. 1B (Siman 1 Bet): Mark I Hybrid, tested with the tracks and chain turret trap protection from Merkava Mk. 2.

Sholef: Prototype self propelled howitzer made in 1984, and 1986. Projet abandoned 1997.

Namera: Prototype heavy armored personnel carrier, from surplus Merkava Mk.1 chassis (2005)

The Merkava I in action

The Merkava Mk. 1 started to fill regiments of the IDF in 1980-85 and experienced its baptism of fire during the Israeli military intervention in Lebanon, 1982 (Operation Peace in the Galilee). US intel reported seven Merkavas destroyed, six by anti-tank mines one by an RPG barrage plus AT-3 Sagger anti-tank missile. Many were more were damaged in combat but hold well and were recovered and repaired, saving thei crews. It was an asymetric fight, against well armed militias in semi-urban combat. To this day, official losses remained classified, but in all thes ecases, the percentage of tankers killed was considerably lower than units fielded with the Shots or even Magach with the Blazer ERA protection. There was particular fight that showed this brillantly: The coastal road linking Rosh HaNikra and Beirut was crossed under fire by Colonel Eli Geva's 211th Armored Brigade, despite constant, suicidal attacks carried out by Palestinian guerrillas spending hundreds of RPGs, AT-3 Sagger and Chinese recoilless guns rounds. There were a few more losses during battles in June and September 1982 at Ain al-Hilweh, Sultan Yacoub and along the Beirut-Damascus road as well, but again, moslt crews survived, showing the resilience of the new main battle tank, and ensuring next evolutions, the Mark II and III.Links/src

Saul Bronfeld, The ‘Chieftain Tank Affair’ Realpolitik, Perfidy and the Genesis of the Merkava 3 nov. 2014Marc Chassillan, «Le Merkava», Raids Hors-Série N°3, 2001

Sam Katz, Merkava Main Battle Tank MKs I, II & III, Osprey Publishing, May 15 1997

« Truck and Tanks magazine » on IDF, june/july 2021

Richard M. Ogorkiewicz, Technology of Tanks, Londres, Jane's Information Group, 1991

fighting-vehicles.com

militarytoday.com

M68_(tank_gun)

tanknutdave.com

armor-il.blogspot.com

www.israeli-weapons.com merkava generic

israeli-weapons.com Merkava Mark I

Israeli Merkava tanks for the armed forces of ukraine truth or fiction

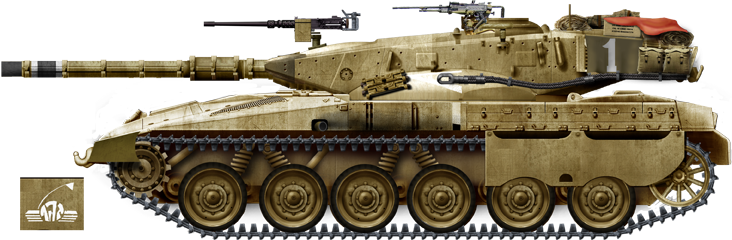

Model unveiled in 1979, entry into service

Early 1980 model, training

Unknown unit 1980

Merkava Mk.1 Z (Zohar) Company Commander, 1982

Merkava Mk.1 of V (Vulcan) Company Commander, 1982

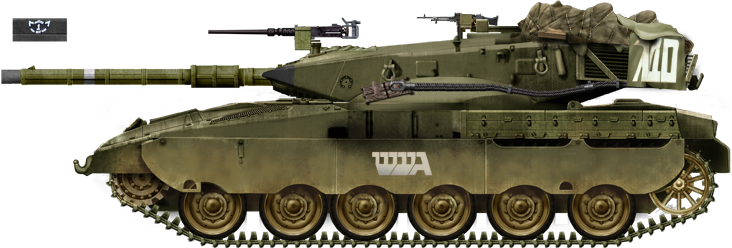

Jezzine C, Lebanon 1983

72th Brigade, Lebanon date unknown

460 Brigade, Lebanon 1988

211 Brigade, Lebanon 1989

Merkava at the Panzemuseum Munster, detail of the folding light

Merkava in evolution at Lesany, from the Museum coll.

Same

Same

Merkava I preserved at Latrun Museum

Merkava I preserved at Batey Haosef

Merkava I preserved at Latrun Museum

Merkava III Dalet Kasag to compare

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com

Tsahal

Tsahal