“Ratel”, the African Bush Fighter

The Ratel is another South African-designed armored vehicle that served in the South African National Defence Force (SANDF) during the late 1970s and 1980s. Developed by the South African company Sandock-Austral (later becoming Reumech OMC and then Denel Land Systems), the Ratel is an infantry fighting vehicle (IFV) designed to transport and support infantry in a variety of battlefield scenarios.Here are some key features of the Ratel IFV:

Role: The Ratel was primarily designed as an infantry fighting vehicle to support mechanized infantry units on the battlefield. It was intended to provide infantry with both mobility and firepower.

Armament: The Ratel is equipped with a turret-mounted armament. The specific armament varies depending on the variant but commonly includes a 20mm autocannon and a co-axial machine gun. Some versions also have anti-aircraft capabilities.

Transport Capacity: The vehicle can carry a squad of infantry, typically around 10 soldiers, in addition to its crew. This allows for the quick deployment of troops to and from the battlefield.

Protection: The Ratel provides its occupants with protection against small arms fire and shell splinters. The design prioritizes mobility and protection, and it is not specifically designed to withstand heavy armor-piercing threats.

Mobility: The Ratel is designed for high mobility, featuring an 8x8 wheeled configuration. This allows it to operate effectively in varied terrains, including off-road environments.

Variants: Over the years, various Ratel variants were developed to fulfill different roles, such as command vehicles, recovery vehicles, and anti-aircraft platforms. The Ratel family includes the Ratel 20 (fitted with a 20mm cannon), Ratel 60 (fitted with a 60mm mortar), Ratel 90 (fitted with a 90mm gun), and others.

The Ratel played a significant role in the South African military during the apartheid era, including operations in neighboring countries. It has also been used by other nations and has seen service in various conflicts. As of January 2022, the Ratel has been largely replaced by newer armored vehicle designs in the South African military, but it remains a part of military history and has influenced subsequent developments in armored vehicle design.

Badger ICV, Waterkloof AFB (Photo: Dewald Venter)

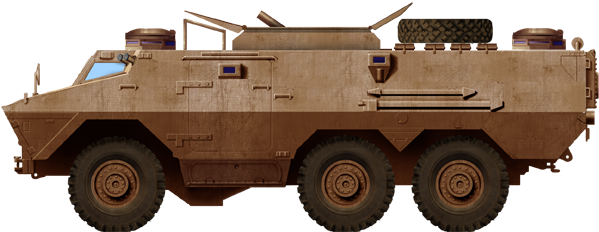

Ratel 20 specifications |

|

| Dimensions (H,W,L) | 7.21m x 2.7m x 2.9m |

| Total weight, battle ready | 18.5 tons |

| Crew | 3 + 8 = 11 (mission dependent) |

| Propulsion | Büssing D 3256 BTXF six-cylinder direct injection turbocharged diesel engine 282 hp (14.8 hp/t) |

| Suspension | Progressive acting coil springs Large hydraulic shock absorbers |

| Speed (road)/(off-road) | 105 kph (62 mph) / 60 kph (37 mph) |

| Range (road) /(off-road) | 1000 km (620 miles) / 600 km (372 miles) |

| Armament | Dual fed F2 20 mm quick firing cannon. 7.62mm co-axial Browning MG 7.62mm turret Browning MG 7.62mm Browning MG in AA mount on rear of vehicle |

| Armour | 20 mm (frontal arc), 8-12 mm (all other arcs) |

| Total production | ~1400 (560 remain in service) |

Concept sketch of a two-cannon SPAAG version based on the Ratel. Image courtesy of Len Bramwell.

Ratel 90

Ratel 90 – Late 1980`s color scheme

Ratel Command Vehicle

Ratel 81

Ratel 60

Ratel 20

Ratel ZT3

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com