Development

In 1956 there was a study over the future needs of the US Army requirements for new heavy artillery system. It emphasised air transportability and rapid deploymnent and extraction, already to avoid couter-battery fire. It also stressed easy maintenance and compatibility by sharing a maximum of parts interchangeability with other models, and greater range. The feasibility study done at the Rock Island Arsenal was carried out, presented and approved at a meeting in January 1956.

Pacific Car and Foundry Company (now PCF Defense Industries) took part in the competition and submitted a concept study. It was a full-tracked armoured self-propelled system sharing a lot of elements with the M113 APC. It thus was awarded a design contract, and for the development and construction of six prototype for field tests: This included two 175 mm self-propelled guns T235 and three 203 mm (8 in) self-propelled howitzers designated T236 as well as a single 155 mm self-propelled gun T245. All three also tested newly developed ordnance or modernized one.

The key feature of the PCF design was interchangeability of all three guns on a common cradle mount with adaptative loading system and common chassis. The base was a 8 inches howitzer cradle that was modified to accept the smaller 155 mm gun field gun, with parts of the M17 standard mount, all modified to match in a working ensemble. This "magic" by PCF engineers managed to achieve a very small package overall, and these drastic reductions in size and weight was all about a brand new hydraulic lockout system which was developed also for these prototypes. Thanks to this, the vehicle could be carried by air as a single ensemble or slinged in two parts (barrel and chassis) by helicopter, or a single crane helicopter that was developed by Boeing at the time.

The chassis was suitable also to be declined into a light recovery vehicle after a quick conversion. The next year in 1957, the programme expanded to include the armoured (T120) and unarmoured (T119 and T121) recovery vehicles and create yeat another development branching out.

The Ordnance service was happy with the first chassis from 1958 but a year after a policy was imposed to replace petrol engines for diesel ones (notably easier to be used as multifuel) for all future vehicles with the prototypes T235, T236 and the T120 retrofitted with a Detroit Diesel Model 8V-71T diesel, becoming the T235E1, T236E1 and the T120E1. Trials with the T235E1 and the T236E1 went on until early 1961. In March both were standardised as the T235E1 as the M107 (155 mm gun-howitzer) and the T236E1 as the M110 (203mm or 8-inches howitzer). The T120E1 was standardised as the M578 ARV while development ended with the T245, T119 and T121.

In June 1961, Pacific Car and Foundry changed policy and stopped taking on army contracts, and was only awarded the initial production contract for the M107 and M110, the first batches being completed in 1962. The first M110 battalion started field tests at Fort Sill in January 1963. Production of the M110 was then transferred to the FMC Corporation at San José, as well as Bowen-McLaughlin-York (BMY) in York, Pennsylvania. Both later merged as United Defense LP., now part of BAE Ground Systems. M110 production ended around 1968 as the war in Vietnam reached its peak. Most already had been deployed there and experience return was generous. Total production at this stage amounted to 750 vehicles.

Towards the M110A1

M110A1 in elevation, 1980s This was however not the development end for this project. In 1969, as the Vietnam war was still raging and there was already plenty of combat experience with the M110, the US Army wanted to field a new generation of ammunition enabling a long range. The US Army Armament Command started development of such improved 203 mm ammunition, and this required modifications of the M110, notably a new longer barrel, that would ned relining or replacement, most already reached the end of their useful life. The main innovation were a much longer 203 mm barrel M201, which was a bit heavier, albeit the structure was made lighter, and was coupled with a direct fire elbow telescope M139.

This was coupled with some re-balancing of the main cradle. There was still no muzzle brake and the remainder of the chassis was more or less left unchanged, apart an overhaul of the engine. This new vehicle was standardised as the M110A1 in March 1976. It entered service in January 1977. It started to replace the M110 and M107, which started to be phased out of service with the US Army in Europe from 1980. Conversion numbers are foggy at that point, but it's possible all vehicles were indeed converted, at Bowen-McLaughlin-York until May 1980.

The M110A2

By FY78, the context of the cold war had changed, notably due to new developments from the Warsaw Pact, and the army wanted to modernized further the M110A1, which chassis and general concept were judged excellent. However it was estimated FY1985 the chassis and engine, as most parts would reach 30 years of age and would need replacement anyway. Alongside, new ammunition was developed, but only maintained by the prospetc of exports. On the long run, the 155mm NATO became the only standard.The M110A2 standardised in 1978 was a M110A1 with a double-baffle muzzle brake with nine M118A1 propelling charge ready versus eight on the M110A1. A contract for 209 M110A2s was ordered at a cost of USD109.3 million, with a delivery deadline for conversion for delivery in 1979-1980. The first was converted in February 1980. The average cost was USD100,000 to convert aither a stock M107 or M110 to an M110A1 or M110A2 standard. In addition to UK and US ground force in the Gulf war in 1991 whereas in Germany as well as the UK and US replaced their M110A2 for Lockheed Martin HIMARS 227 mm Multiple Launch Rocket System. The M110 remained in service for its tactical nuclear capability.

Design of the M110 SPH

The vehicle is essentially a gun cradle mounted on tracks, with ammunitions stored on both sides, with a large slewing ring at the rear half to form the basis for the artillery gun-cradle ensemble. Protecting the crew seemed unnecessary given the new distances of engagement, at up to 10 km out of the frontline. The chassis is powered by a forward-mounted 8-cylinder 356 hp (262 kW) diesel acting on the sprokects forward, as there is no transmission tunnel. There are only four road wheels and idler per side. The most important part in the deployment is the rear-mounted large space, hydraulically lowered firmly into the ground as well as a locker for the suspension to ensure stability after firing and avoid a recoing effect and general fatigue on the drivetrain. Initially only two rounds of ammunition can be carried, stored on the left side, showing a serie of storage wells.General Layout

The hull of the M110 is identical to the M107. It is entirely articulated around the main gun, and for weight balance and space, the engine is at the front and there is an opening to allow the full recoil of the gun's breech-loading tray ensemble. The hull is light, made of all-welded armour with high-tensile alloy steel on the nose to better protect the driver located to the left. Immediately to his right are located the transmission and engine. The upper part of the hull, had typically a serie of exhaust vents for the engine on the left and two bins to store ammunition on the right side. The driver, seated under armour, has a single-piece hatch cover forward with three M17 day periscopes. The hatch can be open for driving out of danger. The middle M17 day periscope can be swapped, as often, by a passive night vision device for driving at night. The M110 has a total team of 13 men in standard operation. Five are the core, commander, driver, three gunners, all seated on the gun, exposed, apart the drive, button on in the hull. The remainder are mostly ammunitions suppliers, following in a dedicated M548 tracked cargo carrier with all the remaining ammunition on board. The latter is a derivative of the M113 APC.

The driver, seated under armour, has a single-piece hatch cover forward with three M17 day periscopes. The hatch can be open for driving out of danger. The middle M17 day periscope can be swapped, as often, by a passive night vision device for driving at night. The M110 has a total team of 13 men in standard operation. Five are the core, commander, driver, three gunners, all seated on the gun, exposed, apart the drive, button on in the hull. The remainder are mostly ammunitions suppliers, following in a dedicated M548 tracked cargo carrier with all the remaining ammunition on board. The latter is a derivative of the M113 APC.

M110 with winter capping

Winterization kits were developed that incorporated covers for the engine exhaust ports and the engine air intake, an engine coolant heating system, and heaters and covers for the operator's and crew compartments. The crew compartment cover is illustrated here, tied down on the left and rolled up on the right. Three dome lights were attached to the cover frame, and the crew compartment heater and ducting can be seen in the right side view of the rolled up cover.

Engine and performances

The Detroit Diesel Model 8V-71T located forward drives the two front drive spocket, and is coupled to the Allison XTG-411-2A, cross-drive transmission with access and service hatches above. The drivetrain consists on four roadwheels, stamped, dual, rubber-tyred, same type as the M113 from FMC. In all there are five, as the last one, levelled with the others, as there are non return rollers due to size constraints. This made for a minimalist ground train, able to correctly move on all terrain with a limited ground pressure still. These roadwheels are suspended by torsion bar suspension, with in addition hydraulic shock-absorbers and an hydraulic bump stop plus suspension lockout unique to the type. When it is able to fire, rear spade firmly planted, the suspensions are "hardened" to pass all recoif forces to the ground. Tracks are standard single-pin type with removable rubber pads, similar to the M113.. The M110 engine power output is 405 hp, which allowed a top speed of 55 kph at best, but later modification reduced this to 38 kph. Max range was 523 km in 1960. The M110 could climb a vertical obstacle of 1 meter, gap a 2,3 meters trench and ford without preparation 1,20 meters. It was not amphibious.

Main Gun

The 203 mm (8 inch) M2A2 howitzer inside its M158 mount is the largest ordnance ever fitted to such small chassis. It had a an elevation of +65°, depression of -2°, traverse of 30° left and right enabling rapid change or objectives while staying fixed. Elevation, depression and traverse are managed by an innovative hydraulic system, with manual controls as backup (handcranked). The hydropneumatic recoil system is coupled with a breech showing an interrupted screw block and percussion mechanism to fire, all tightly integrated.On its left side is the rammer and loader assembly. Its role is to power lift the projectile laid at its rear or left, ramming it into the chamber. The fire-control system comprises a panoramic sight M115 with a magnification of ×4, 10° FOV, setup for indirect fire. It is coupled with a telescope M116C with a magnification of ×3 and 13° FIV for direct fire. There are in addition an elevation quadrant M15 and gunner's quadrant M1A1.

Ammunitions

Ammunitions are separate, with two rounds carried on the vehicle, two shells and two charges on the left side. The other rounds are carried by the M548, 37 total. A standard rate of fire is a single round every two minutes. Howver in rapid fire mode with a well-drilled crew and no change in aiming, two rounds a minute is possible for short bursts.conventional Ammunition:

- HE M106: 92.53 kg, MV 587 m/s, RA with with charge 7 7 16,8 km

- HE M404: 90.72 kg. Warhead filled with 104 M43A1 grenades. PV 587 m/s RA with charge 7 16,8 km

- HE M426: Filled with agent GB Sarin (now decommissioned).

- M422A1 Artillery Fired Atomic Projectile W33 (see below)

- M424 High Altitude Spotting Round working with the M422

- HE M106 92.53 kg charge 8: MV 711 m/s, RA 22,9 km

- HE M404 90.72 kg charge 8: MV 711 m/s RA 17,2 km. Payload 104 AP grenades

- HE M509A1, charge M188A1 Payload 80 AP/AM grenades, RA 22,9 km.

- HERA M650 charge 9 RA 30 km

- XM753 Atomic RA (rocket assisted)

Modernized Ammunition (A1; A2):

W33 Nuclear Ammunition (1953)

Called the Mark 33, T317 and M422, it was developed from June 1953 to be more cost-effective to launch from a Howitzer, while also providing a psychological effect on the battlefield. The same shell was supposed to be fired also by the navy 8-inch (203 mm) gun still in service on many heavy cruisers of the USN. It was called the W9 11-inch (280 mm) nuclear artillery shell, usable for coastal bombardment. Called at first "Shell, AE, 8-inch, T317" its Atomic Energy Commission nomenclature was Mark 33. The army had to design and built, stockped all non-nuclear components, and the AEC all the nuclear components.

Funding as obtained in February 1954 and in April a service target for July 1955 was selected. Approximately 2000 were produced, all retired by September 1992 due to SALT limitation treaties. Nominal range was 18 kilometres (11 mi) and yeld depending on the preset variants called Y1 through Y4, classified, but estimated later from 40 kilotonnes down to 5, with later declassified British document giving 10 kt TNT or 42 TJ. For memory this is the equivalent of a total destruction over a mile in circumference, and moderate damage over 4 miles. Several howitzers were used during the cold war for such weapons.

W79 Nuclear Ammunition (1975)

Called the The W79 Artillery-Fired Atomic Projectile (AFAP) or XM753 (Atomic RA) this model was compatible to NATO 8 in (203 mm) howitzer of the M115 and M110, and produced in two models with the enhanced radiation (ERW) W79 Mod 0 and fission-only W79 Mod 1, both plutonium-based with linear-implosion. The first had yeld settings from 100 Kt down to 1.1 kt with optional enhanced-radiation mode while tje Mod 1 had a fixed 0.8 kt yield. Production started from July 1981 until August 1986 for a total of 550 warheads (325 Mod 0s, 225 Mod 1s). They were retired by late 1992, the last dismantled at Pantex, Texas, by August 2002.Personal Weapons

Unlike self propelled guns and howitzer of WW2, the M110 is a pure howitzer on tracks, with very limited ammunitions, no protection for the crew and no self defence arament. A full crew of 13 could provide a lot of local firepower, with the standard dotation of the infantry attached to the artillery brigades, small arms like the M14, grease gun and grenades.Users

Belgium: 11 M110A2 20th Art.Rgt. 1972-93

Belgium: 11 M110A2 20th Art.Rgt. 1972-93 Barhein: 61* M110A2 (38; 13 ex-NK 1994 +25 ex-US 1996)

Barhein: 61* M110A2 (38; 13 ex-NK 1994 +25 ex-US 1996) Cyprus: 8 M110A2 wit the National Guard

Cyprus: 8 M110A2 wit the National Guard Germany: 80 M110> 230 M110A2 until 1993*

Germany: 80 M110> 230 M110A2 until 1993* Greece: 145 M110A2, active

Greece: 145 M110A2, active Egypt: 114 M110A2 in 1996

Egypt: 114 M110A2 in 1996 IDF: 36(72) M110 retired 1990s.

IDF: 36(72) M110 retired 1990s. Italy: M110A2s phased out 1993.

Italy: M110A2s phased out 1993. Iran: Pre-revolution, 30 M110s.

Iran: Pre-revolution, 30 M110s. JSDGF: 91 M110A2 as of 1990+, 10 active 104 ArtBat 4thArtGp Hokkaido, disb. 2024.

JSDGF: 91 M110A2 as of 1990+, 10 active 104 ArtBat 4thArtGp Hokkaido, disb. 2024. Jordan: 120 M110A2, active

Jordan: 120 M110A2, active Morocco: 60 M110A1

Morocco: 60 M110A1 Netherlands: M110A1 and M110A2 until replaced by the M109

Netherlands: M110A1 and M110A2 until replaced by the M109 Pakistan: 40 M110A1

Pakistan: 40 M110A1 South Korea: M110 from 1961 until 2000s (K9 Thunder))

South Korea: M110 from 1961 until 2000s (K9 Thunder)) South Vietnam: Former M110s from 1969.

South Vietnam: Former M110s from 1969. Pakistan: 140(12*) M110A1 in 2021

Pakistan: 140(12*) M110A1 in 2021 Taiwan: 75 M110A2

Taiwan: 75 M110A2 Turkey: 219 M110A2, replaced by the T-155 Firtina

Turkey: 219 M110A2, replaced by the T-155 Firtina UK: M110A2s firing HE and Nuclear shells.

UK: M110A2s firing HE and Nuclear shells. US Army, USMC 239 M110A2 kept until 1994, nuclear-capable

US Army, USMC 239 M110A2 kept until 1994, nuclear-capableGerman Artillerie-Selbstfahrlafetten M110

To strengthen its firepower for the artillery branch, the Bundeswehr acquired the M109G, M107 SF and M110 SF in 1964. They replaced the towed M59 "Long Tom" and M115 field howitzers. The bundeswehr army structure came into effect in 1970, and the field artillery battalions in the 2nd and 3rd Batteries were equipped with six M107 field guns each while the 4th Battery received six M110 field howitzers.Restructuring involved the conversion of the 150 M107 to extra M110s while the existing 80 M110 howitzers received the new 8.26 m long L/37 barrel and distinctive dual-chamber muzzle brake of the A2. Thet also had now a weatherproof hood. The track system was modernized with double-block tracks from Diehl instead of the original, and installation of a data input/output device to integrate all 230 M110A2 wit the new integrated fire control system (IFAB), for a total weight of 28.4 tons and top speed down to 30 km/h.

The divisional field artillery battalions ended with six M110 A2 each and the corps field artillery battalions, 3 batteries of 6 M110A2 each. "Artillery Structure 85" led to the dissolution of the corps artillery in 1985 and they were transferred ti artillery battalions, remaining until decommission in 1993, 9 guns each, in the 4th and 5th batteries.

M110 in service

Vietnam, and the Gulf War (In redaction).

M110 specifications | |

| Dimensions | 35 ft 5 in x 10 ft 2 in x 10 ft 2 in (10.8 x 3.1 x 3.1 m) |

| Weight | 31.2 short tons (28.3 t; 27.9 long tons) |

| Crew | 13 (driver, 2 gunners, 2 loaders +8 in support crew, other vehicle) |

| Propulsion | Detroit 8V71T, 8-cyl. 2-stroke TD 405 hp (302 kW) |

| Suspension | Torsion bar |

| Speed (road) | 30 mph (54.7 km/h) |

| Range | 530 km |

| Armament | M201A1 203 mm (8 in), RA 16.8–30 km (19 mi) |

| Armor | 0.51 in (13 mm) |

| Total production | 750 |

Illustrations

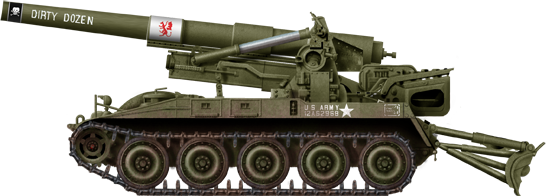

M113 South Vietnam, 13th Field Artillery Egt. 3th Batallion D-Company, 1968

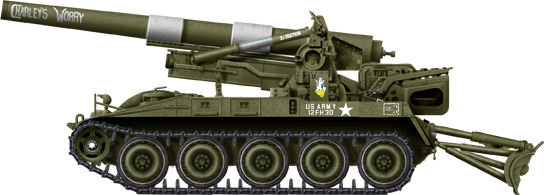

M110 "Charly's Worry" 83th Field Art.Rgt. 1st Bat. C-Battery "FSB Sally" South VN 1970

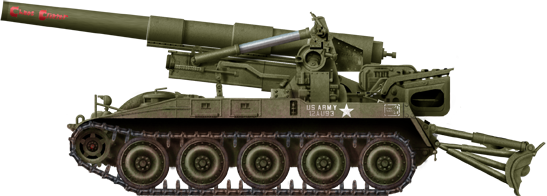

"Chaos Carrier", 11th Field Artillery Rgt. 6th Bat. C-Battery South VN 1970

M110 "Mount St Helen", reserve unit in the US, late 1970s.

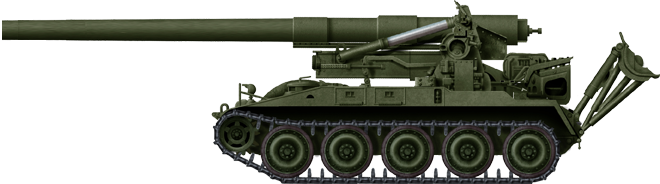

M110A1

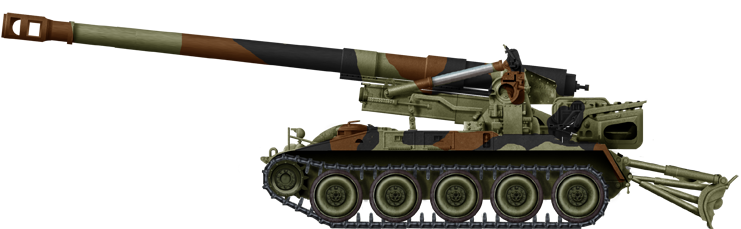

Camouflaged M110A2

Camouflaged M110A2

Photos

Moroccan M110A2

M110A2 tested in Asia

M110 in Vietnam

Japanese M110A2

Bundeswehr M110 in the 1960s

M110 in Vietnam, firing

M110A2 landed to take part in the Gulf War, 1991

M107 Howitzer self-propelled gun at An Hoa, May 1970

M110 Chaos Creator Vietnam

M110 in Vietnam

More

Links

armyrecognition.comarmedconflicts.com

militaryfactory.com

afvdb.50megs.com

combatoperators.com

keymilitary.com

armyrecognition.com/

weaponsystems.net

army-guide.com

hhs.gov/

panzerbaer.de

tankmuseumshop.org

Video, Australian Museum

Video

Model Kit:

On scalemates

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com