Development of the Arjun

About DRDO

The Combat Vehicles Research and Development Establishment, or "DRDO" was created in March 1975 at Chennai, to beter gather technicians, engineers in the same spot, in the wake of the Indian domestic tank program started in 1972. Most of its former assets came from the Chief Inspectorate of Mechanical Transport Establishment (MTE) in Chaklala (Pakistan) moved to Ahmednagar. It became the "Vehicle Research & Development Establishment" or VRDE. In 1965, the Heavy Vehicles Factory created at Avadi to manufacture the Vijayanta Tank saw an adjunction from VRDE there to provide R&D support. In March 1976, this Avadi detachment was separated from VRDE and became, and then the independent DRDO laboratory, now the exoert center of Armoured Fighting Vehicles in India. CVRDE was responsible for the development of the Arjun MBT but worked also on the Tank-EX, Bhim Self Propelled Artillery and Improved Ajeya (T-72 upgrade).

Early development

The previous Vijayanta always has been seen as a stopgap measure, a local tank based on the export Vickers medium in the early 1960s. After the war of 1965 it appeared clearly to Indian army planners that the latter was no longer relevant and in 1972 was signed the development of a new tank, entirely designed and built in India. DRDO's CVRDE main laboratory was tasked to develop the hull, armour and turret as well as the running gear and gun. Only the powerpack was considered to be imported. Nevertheless, these researches proceeded slowly and the vagaries of politics meant the project was underfunded. In 1977 it was estimated the new domestic tank would not ready for production before perhaps five to eight more years. Since a new model was urgently needed to replace the old Centurion and Vijayanta models, prospects were made to the international market.

Early demonstrator, now exposed in Mumbai.

Delays and the Ayeja program

In 1978 already, French & British Proposal to replace the Vijayanta were received. Firepower and mobility characteristics were to be offered for full in-country production. These were respectively the French AMX-40, developed by GIAT Industries, and the Chieftain 800 (a precursor to the Challenger 1), from the Royal Ordnance Factories owned by British Aerospace. The Indian Army conducted dozens of comparative tests. By early 1980 the 43-tonne AMX-40 MBT, still on the drawing board, was chosen. It relied on a 1,100 hp Poyaud V12X 12-cylinder diesel engine, coupled with a German LSG-3000 automatic power shift transmission (by RENK). With a power-to-weight ratio of 25.6 hp/tonne, it was much faster and had the same 120 mm smoothbore cannon as it contenter. However its protection was very poor by the standards of eighties.When she came back to power, PM Indira Gandhi requested additional evaluations, including the T-72M from the USSR (172M-E4 MBT off-the-shelf) and started negiociating for a licensed-production at the state-own Heavy Vehicles Factory (HVF) in Avadi. This became the T-72M Ajeya, produced to a total of 2,400 Ajeya MK1 an late production MK2. They helped replacing the intended tanks and maintain India's capability in terms of numbers with cost-efficiency. The whoe program led to the "Improved Ajeya" led by DRDO incorporating many advances made for the Arjun, which entered production in the meantime.

The arjun program is back on track

It's only from 1996 that the Indian government decided to mass-produce the tank still in development at the Indian Ordnance Factory's production facility, in Avadi. To speed things up, the government imposed the new MBT would used as many foreign components and technology as possible, in spite of the origin of the program in 1972. In the end, the Arjun had close to 50% of its components imported, including the engine, transmission, gun barrel, tracks, and fire control system. They allowed the Arjun to enter service as scheduled, but development went on to replace all these systems by Indian ones, leading eventually to the Arjun mark 2. In total, the Arjun development time spaned for over 37 years.Army sources indicated that the Russian T-90S will stay as the bulk of the armoured forces, making de facto the Arjun an "elite" tank. In the end, the Arjun project, as any new ambtious one, experienced serious budget overruns, repeated delays ending in a public scandal and some resignations. India had no previous experience in designing a sophisticated tank from the ground up, while facilities and research infrastructures also were lacking. During the project also, advances in technology and new threat led to multiple new requirements by the Army, which imposed multiple design revisions along the way. The MoD was awarded for this project ₹15.5 crore (₹374 crore/US$52.4 million as of today) just for the initial design phase, in May 1974. As of 1995, ₹300 crore (US$201.7 million) on development and R&D, making this program the costliest in Indian history. DRDO nevertheless in a sense succeeded in having this 35+ years old design constantly updated, making a true Generation III main battle tank on par with International standards.

Gunsight simulator for the Arjun

Finalization of the production and service

In 1996, the development of the PPS 15 tank prototype started to fix all the Arjun problems listed by the Army. In 1997, a new plan was formulated to fix all the shortcoming with the goal of an actove service introduction as soon as possible. In 1999, the Army and the Cabinet Committee on Security at last were satisfied by the last test batch and ordered a pre-production run of what became the Arjun Mark 1, based on the PPS-15 prototype. Fields Tests were successful and the next year in 2000, the government placed a new order for 124 Arjun MK1. The first PPS-15 delivered was received by the 43rd Armoured Regiment, and made a public appearance in 1997, and the 2001 Republic Day Parade.Serial production really started in 2003 (after tooling HVF Avadi for it, in three years). The first production tank was fitted with BEL's Integrated Fire Control System (IFCS), a new ballistic computer and new gunner's main sight. It was accepted in 2004, delivered with four others on 7 August 2004. The first tranche went to the elite 43rd Armoured Regiment in 2004. In 2009, two armoured regiments had the Arjun Mark 1. Test firing with the LAHAT ATGM were preformed also in 2004.

In 2006, it was time to create a unit maintenance and repair vehicles for the Arjun for all equipped regiments. In 2008 a new feature was proposed on some test tanks, a multi-purpose mobile camouflage system (MCS) -part of the Defensive Aid System (DAS) plan. They were successful after field evaluation trials in 2009. The same year was introduced an advanced laser warning countermeasure system (ALWCS) and also a fiber optic gyro based sensor integrated on the MK1 in production after successful field trials in May-August. The Armament Research & Development Establishment perfected the recoil system, tested and sent to HVF Avadi for integration, with 124 on order. In 2010, a combat simulators was developed specfically for the Arjun. By June 2011 the MoD announced that the milestone of 100 had been reached, all delivered to the Indian Army. The treshold of 124 tanks was reached in 2012, however in 2015, a lack of spare parts had most operational units grounding their tank, until this was rectified in 2016. Meawnhile R&D went on and a brand new generation was already on tracks.

ATGM fired from a modified Arjun turret over an Ajeyah chassis, for the new Tank EX light Indian Tank.

Upgrades program and the Arjun Mark 1A

In 2010, DRDO proposed the Arjun MK2 which design was finalised in mid-2010 in concertation with the army. 89 major and minor improvements were listed, for firepower and survivability and of these, mostly minor, could be fitted on the existing Mark 1. The Indian Army placed an order 124 Arjun Mark 2 later approved by the Defence Acquisition Council. In 2011, the first Mark 2 prototype was completed, integrated 20 of the improvements planned, delivered to the army for the validation trial phase 1: It had notably a new commander's independent panoramic sight In 2012, the first complete prototype with all improvements entered validation trial phase 2. LAHAT ATGM fire trials started in 2013 and in 2015, DRDO developed and finalized the Integrated Automotive Vetronics System for the prototype, followed by field trials over 430 km in the most harsher environmental conditions met in India. In 2014-2016 two new ammunitions were introduced, the Penetration Cum Blast and Thermobaric round, both tested and approved for producrion. The army eventually decided to rename te production vehicle awaited the Arjun Mark 1A and in 2018, two more prototypes underwent trials, until the pandemic came in. As of today, production is scheduled to start this year, in 2021, delayed by the world's Pandemic, which also badly hit India. As for the Mark 1, the first batch will be a pre-production test one for operational field trials in active units, followed by another main order, not yet announced.Design of the Arjun Mark 1

Armament of the Arjun

Main armament

The Arjun used a locally developped 120 mm rifled gun, fitted with a recoil system developed by ARDE, and including a muzzle reference system and fume extractor. Comparable to both Russian and Western standards for 3rd gen MBTs, thus gun could fire both guided (ATGMD), and unguided ammunitions. The main gun lining used a high strength electro-slag remelting (ESR) steel, insulated with a thermal sleeve and autofrettaged.The newer MK1A just add to this an improved barrel, waitning perhaps for an adaptation of the Indian 125 mm smoothbore gun coming from the T-90 under license production. The Arjun MK1 is capable of firing several types of amunition, most locally developped:

-Armour-piercing fin-stabilized discarding sabot (APFSDS)

-Dual purpose high explosive squash head (HESH).

-HE (high explosive), either with penetration Cum Blast (PCB) and Thermobaric (TB) for urban combat. Usual provision of the Mark I is 42 APFSDS and HESH. They are all contained in a blast-proof canister equipped with blow out panels, now standard to protect the crew. In 2017, the Mark 1A introduced a new APFSDS model with a long rod tungsten alloy penetrator by ARDE. This APFSDS Mark 2 is reportedly havinb a much better penetration performance.

-SAMHO ATGM: For the LAHAT gun variant, and anti-tank guided missile was developed, cancelled in 2014 but replaced by the CLMDP viz, better known as SAMHO. In 2020, after successful tests, it was adopted. It was developed by ARDE with the High Energy Materials Research Laboratory (HEMRL) and the Instruments Research and Development Establishment (IRDE). This missile possessed a HEAT warhead in tandem to defeat ERA. It is developed also to fight off low flying attack helicopter as close as 1.5 km, up to 5 km, giving the tank a true all-around hitting capability on the battlefield.

Secondary armament

-12.7 mm NSV heavy machine gun, placed forward of the gunner's hatch. It could fire tracers, incendiary, HE and AP rounds on armoured and softskin vehicles, engage low flying aircraft and attack helicopters. Manually operated, on the MK1A it is placed in a remotely operated gun turret, from inside the tank. Ammo supply is around 900 rounds. -Coaxial 7.62 mm light machine gun firiing standard interlocked tracers rounds, about 2,000 in storage.Fire control systems

The Arjun is given an Indian fire control system (BEL viz), Integrated (IFCS). It comprises the following:-A Sensor mast, able to provided data from the wind speed, temperature among opthers

-A digital ballistic computer (compiling information from sensors like the gyro, laster and sights (tilt angle, target range and speed) delivering the firing solution. -Gun control system, full stabilized electro-hydraulically on 2 axis. The Arjun's IFCS work for quick target acquisition, ensuring the first round-first hit probability, day and night in weather. The stabilition system work for all terrain at any speed while moving and it is interfaced with the IFCS for high accuracy. This system was also integrated into the licence-built Indian Army T-90 tanks (Bhishma).

-Gunner's main sight: Integrates a laser rangefinder, 2x mag day sight, thermal sight. Uses a fibre-optic gyro 2-axis stabilization, integrates a automatic target tracking system as well.

-Commander's panoramic sight: Independent of the turret, stabilized by fibre-optic gyro, integrated laser rangefinder, 2x mag day sight, thermal imaging camera and 360° surveillance. It is also interfaced with the ballistic computer to override the gunner and engage targets or ensure an efficiet hunter-killer mode.

-MK1A In addition has an integrated laser target designator for the SAMHO ATGM.

Armoured protection

Armour Protection

The Arjun MK1 was given an Indian developed armour set called the Kanchan armour (related to Kanchanbagh, where the Defence Metallurgical Research Laboratory is based). The latter designed and developed this system, comprising classified composite armour with ceramic tiles, composite panels sandwiched inside RHA plating boxes. Extensive tests ensire it can defeat the latest APFSDS. The reast of the hull and NERA is protected by using ultra-high strength low alloy, called "DMR-1700 steel" also developed by the DMRL. It is optimized against kinetic energy penetrators (APFSDS 125 mm) and the RHA plates are proof 20%-25% against 7.62 to 12.7 mm AP rounds.The Arjun MK1A introduced an imroved armour turret design called "improved Kanchan". It offers enhanced protection against large APFSDS projectiles, HESH and HEAT with an improve set of additional ERA panels covering the turret side, hull glacis and side skirt. The armour set also integrated non-explosive reactive armour (NERA).

Active protection

The Mk1A turret was modified to have a reduced silhouette for modern electro-optical sights standards. There is a multi-purpose mobile camouflage system (MCS) integrated and certified in 2009. The anti-infrared/anti-thermal paints reduce its infrared signature. For a more active protection system, the Arjun MBT is equipped with the Advanced Laser Warning Countermeasure System (ALWCS): consists Four laser warning receivers (on the top of the turret, on a 360° field). The ALWCS alerts the crew, indicate the laser direction, and the Arjun illuminator is pointed at the vehicle. The ALWCS also integrated IR jammers. In addition there is an aerosol fired by the smoke grenades. The ALWCS is also interfaced with the Arjun FCS and served autonomously the grenade launcher, oriented towards the incming threat. There is a backup manual mode in case.Active crew protection

The crew benefits from collective NBC protection, plus the standard automatic fire detection and suppression system. The crew of four (commander, gunner, loader and driver) has well-thought ergonomics for crew safety & comfort. The engine compartments is also equipped with an automatic fire detection and suppression system, woriong automatically with its heat sensor with a reaction time of 200 milliseconds. The ammunition rounds are stored in the containerised ammunition bin in the turret basket, encloded withing individual shutter, with blow off panels (ammunition cook off danger). The MK1A adds to this a forward mine plough to defeat anti-tank mines.Powerplant

The Arjun's wheeltrain compries seven roadwheels per side, suspended on Indian-designed hydropneumatic suspensions. There is a front idler and rear drive sprokect as usual in this standard configuration. The Arjun is powered by a German-licenced built MTU 838 Ka 501 turbo charged 10 cylinder. It is a liquid cooled diesel engine which rated output is 1,400 hp at 2400 rpm. Top speed is 70 km/h top speed (governed) on roads, down to 40 km/h cross country. Fuel capacity is 1,610 litres ensuring a range of 450 km. The MK1A is given a redesigned hydropneumatic suspension system with a dynamic, advanced running gear system, autmatically adapated on all speed and terrains. Mk1 tracks are German, from Diehl and later Larsen & Toubro on the Mk1A.Arjun ground clearance is 0.45 metres. On trials, it proved able to ford 2.15 metre deep almost without preparation, just redirecting the air for fuel combustion through the commander's and loader's hatches. Not amphibious kit has been developed yet.

The MK1A added to its powerplant an auxiliary power unit (APU), doubling the power generation capacity, or providing a silent watch mode with the main engine off. It is supplying all weapons systems and the FCS at all times. The use in "sleath mode" of the APU also reduces the IR/thermal and acoustic signatures, perfect for ambush tactics. The Arjun MK1A also integrated in the turret the Advanced Land Navigation System (ALNS). It is added to the Mk1 GPS/inertial navigation system. Its antenna and inertial-star base night camera is fixed on top of the extensive sensor mast of the Mk1A. Also on the MK1A variant, the driver uses an uncooled Night Vision camera and thermal imager, with binocular vision for secured night driving.

Design of the Arjun Mark 1A

The Mark 1A shares many elements in common with the Mark 1, but externally the most striking, visible element if the modular ERA armour package added to the furret front, reminiscent of the Leopard 2A6. Other details are the sensor mast, additional cameras, semi-remote operation of the NSV heavy MG, and new sights. The vehicles has the same lenght at 10.6 m gun forward, for 3.9 m and 2.32 m in height at the roof but weighs ten tons more, at 68 tons. It is propelled for the moment by the same powerplant, the 1400 hp MTU 838 Ka 501 turbo charged diesel rated for a 450 km range. Although better protected, the Arjun 1A due to this lack of upgrade had a far les power to weight ratio and top speed fell from 70 to 58 kph (governed), a loss of 12 Kph. The drivetrain does not change, nor the four men crew, but the 120 mm rifled gun could fire more ammunitions, between the APFSDS HESH, PCB, TB, SAMHO and Lahat ATGM. The Secondary HMG stays the same cupola-mounted 12.7 mm HCB with an optional remotely operated gun turret. There is also the same coaxial 7.62 mm Tk 715 A.Protection has been revised a great deal, and incorporates the Improved Kanchan, ERA and NERA system, but still calls for the same multi-spectral mobile camouflage, anti-infrared/anti-thermal paint, and the two models uses the same Advanced Laser Warning Countermeasure System (ALWCS), with IR jammer integrated. The Mark 1A however inregrates two more smoke dischargers (four banks instead of three, 16 total).

The MK1A integrates as seen above, 89 major and minor improvements, notably its gunner's main sight which enables an automatic target tracking system, the new commander's panoramic sight CPS MK-II with laser rangefinder, dual magnification and interfaces uncooled thermal sight for an improved hunter-killer capability. There is another uncooled sight system integrating a with binocular vision for the driver. The remote weapon station is also quite a novelty. Externally another easy giveaway is the front-mounted mine plough. More difficut to spot is the internall rear turret containerized ammunition bin, with an automatic blowout system and fitted with an individual shutter for crew safety. The TC also benefits from an advanced land navigation system. There is also a new auxiliary power unit (APU) more powerful while the hydropneumatic suspension was redesigned with the "new advanced running gear system" (ARGS).

Variants

Arjun MK1: First production variant inspired by theo Leopard 2A4 (2004) 58.5 ton, Kanchan ERA and a 120 mm rifled gun.Bhim SPH: 155 mm self-propelled howitzer variant using the Denel T6 turret/G5 howitzer. Cancelled after a corruption scandal.

Arjun Catapult System: 130 mm self propelled howitzer similar to the Vijayanta catapult systemn, 40 ordered.

Bridge Layer Tank: AVLB base don the Arjun chassis (CVRDE) with scissors type bridges.

Arjun ARRV: Armoured recovery/repair vehicle used as CVRDE and BEML in tank regiments

Tank EX: Hybrid experimental prototype of a light tanks with T-72 (Ajeyah) chassis and Arjun turret.

Arjun MK1A: In short: 89 improvements, Improved Kanchan/ERA-NERA, SAMHO ATGM, new sights, new FCS, mine plough, CABIS, NAVSAT, APU, immroved hydropneumatic suspension, ARGS, RWS.

Future program, FY2030: Arjun Mark 2

Either called the "Arjun MK2" for marketing purposes, the Next Generation Main Battle Tank (NGMBT), also sometimes called Future MBT (FMBT) is a new main battle tank developed by DRDO, considerably lighter than current Arjun variants and notably the Mk1A in order to reclaim mobility. But its is also planned receive advanced electro-optical sight systems, and an expected high power laser based weapon system, but maintaining its main gun of which the calibre has not been decided, but probably 125 to 130 mm and firing larger projectiles at greater ranges. The FMBT also crucially will have the network centric warfare capabilities the Mk1A lacks. The FMBT should be however cheaper in order to replace the T-72 Ajeya, no less than 50 tonnes with a 1,500-1800 hp indian power unit and automatic transmission system (the "Bharat Power Pack"). The modular design also allows for additions and transformations on the long run. The FMBT development started as soon as the Arjun MK1A itelf reached operational status (on going). It is expected to be operational FY 2030, but is noticeably heavier than the "tank EX".Illustrations

Arjun Prototype "Ganesh" in 1989

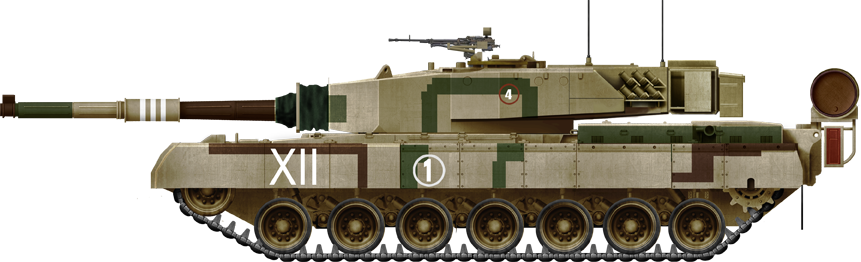

Arjun Mark 1 in esert livery, active unit exercizes

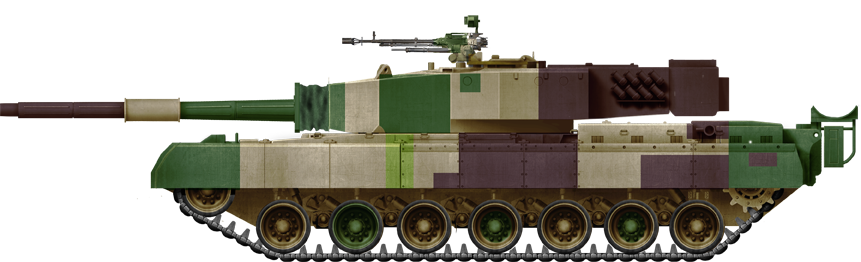

Arjun Mark 1 with a northern camouflage

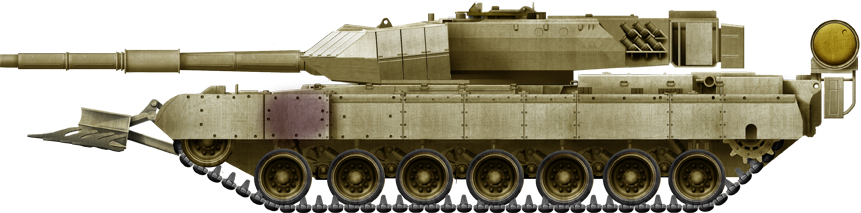

Early Mark 1A in base beige livery and partial turret armour

Arjun Mark 1A camouflage with full armor, 2020

Gallery

Arjun Mark 1 in a parade, Republic day

Tank side

Arjun 1 at the 100th indian science international congress in Kolkata, 2013.

Mk1 of the same unit parading in Republic Day 2013

Mk1 at the Rajpath parade

PM S. Nahendra Modi on a Mk1 at Longewala Jaisalmer, Rajasthan November 14, 2020

Arjun Bridelayer

Mk1A in field trials

Arjun Mark II side

Bump track tests

Videos

Modern Tanks

Modern MBTs posters

Denel Bagder (2018)

Type 16 MCV (2016)

Gepard 1A2 last rounds 2011

SANDF

Russian AFVs

Main Battle Tanks