The birth of both two of the world's most iconic main battle tanks today, the Abrams and the Leopard 2 was a 1960s joint US-West German program, known either as the MBT-70 and the Kpf-70. It was developed in the context of the Cold War, to counter the latest generation of Soviet main battle tanks. It was technically ambitious and a true departure from previous designs (Notably in the US such as the M48 and M60 patton) with advanced features such as kneeling" hydropneumatic suspension plus housing the entire crew in the turret, which housed a 152mm XM150 gun/ ATGM launcher compatible with the MGM-51 Shillelagh.

This program met many challenges from the start from communication to coordination and eventually industrial disputes between US and West German teams. Diverging requirements never aligned and were left unresolved while the project advanced too far to be revised, with spiralling costs. West Germany withdrew from the project in 1969 but the US prersevered with the MBT-70 until 1971 until cancelling it and reorienting the teams and funds to the XM1 Abrams. West Germany started anew and developed the Leopard 2.

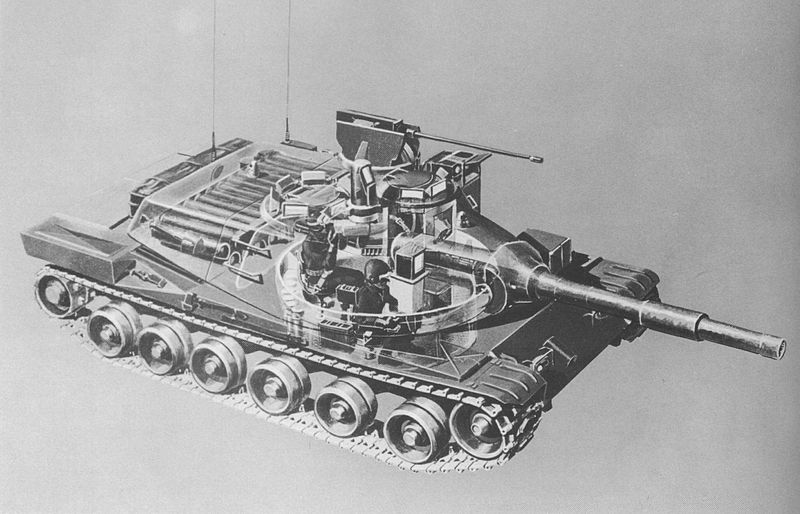

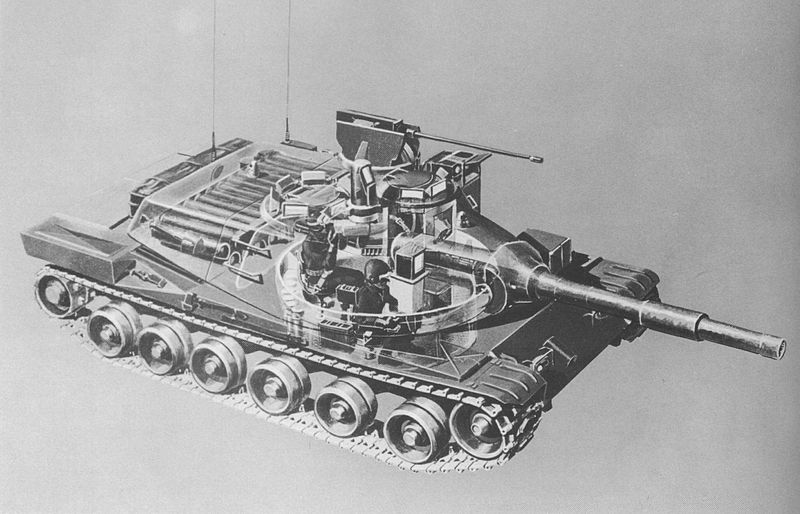

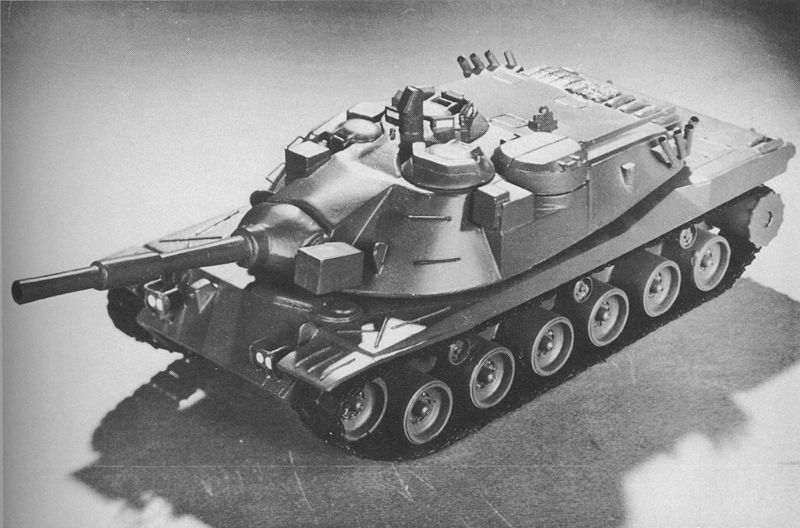

Cutaway of the MBT-70

The third objective was more global. NATO member states at the time had a disjointed park of heteroclitous tanks and armoured vehicles, lacking common ammunition, fuel and parts, a nightmare of logistics if war broke out. Joint programmes were rare, although a political push for it, and this also included tanks. Up to that time one of the most famous failure was the Europanzer. Both countries poartes they ways and created the AMX-30 and leopard I, both widely exported.

But while the career of the Leopard I was hust getting started, West Germany still used American M48 Pattons, and was now moving on full domestic designs. McNamara regarded Germany as a more and more important and central member of NATO, believing that a joint development, backed by the might of US indistrial output, with a project infused with German tech, could provide NATO members and allies outside NATO a solid, universal main battle tank up to the challenge and at a much lower cost. Covering both West German and US needs already allowed to keep the cost lower than competitive purely national programs, at least on paper, and with prospects of exports (and perhaps even some purchases from Britain and France), statistics looked even sexier.

In 1961 (for context the Europanzer program was just getting started) McNamara approached German Minister of Defence Franz Josef Strauss starting a collaborative main battle tank program. But instead the latter suggested the U.S. should instead directly buy the Leopard 1 then in development... Strauss however agree to a common component program to lower costs. McNamara accepted but continued to lobby for a larger tank program cooperation and succeeded with a tentative agreement with West Germany in 1962.

Meawnile the US Armor Branch pressed the Pentagon to finance a successor to the M60 Patton, seen merely as an improved M48, a technology which traced its lineage back to the Pershing heavy tank. But McNamara's long (seven-year) timeline did not met senior armor officer's demands while others questioned McNamara's fascination of German engineering adn that it was not on par with its level in 1944, while struggling to keep pace with innovations or lack of financing. Some thougfht this would be a risky, net technology transfer towards Germany, alsways in risk of falling overnight to a Soviet attack, while the UK would make a better partner. France under De Gaulle was of course out of question. McNamara instead argues the country's excellent economic wealth, dynamic industrial sector as prven by its successful post-war "economic miracle" and the best placed in Europe to commit to a such a project.

The issue was to agree on a common program that could meet the requirements of both armies. So in August 1963, Germany and the United States signed a memorandum of understanding specifying certain desired characteristics. A Joint Engineering Agency was created as well as a Joint Design Team with 50% representation on both sides. But soon, differing engineering practices started to undermine the project, and this went on until the end.

Turret design In 1963, General Welborn G. Dolvin (former tank commander) was chosen as project manager, at the head of the US team and three contractors were soon in the loop, Chrysler Defense, General Motors and Ford/FMC joint venture. General Dolvin trusted GM more to bring fresh ideas instead of Chrysler tbat for too long had been living on the "rent" of producing US tanks. In Germany, a Development Corporation was formed with several German firms, including those that would later be part of Rheinmetall and Krauss Maffei Wegman. In first phase, GM engineers flew to Augsburg to work with German engineers, but to manage them, and in a second phase, it would be the reverse, to streamline practices, at GM's factories in Detroit.

But disputes soon arose over every element of the design and the use of metric and SAE units plagues communication and augmented chances of incompatibility. These were found in many shared manufactured components, which repartition to the two countries proved delicate. These constant disagreement went to the ear of to McNamara and MoD Kai-Uwe von Hassel. They ultimately failed to force the use of a common measurement system and so both side stuck to their own preferred measurement, applied to the parts they designed and produced. Common metric became however standard in all interface connections and welding parts.

But extra complexity created delays in development timetable. Of course the budget ros as well quickly. Different methods of projection in production, even the way the blueprints were laid out cause extra confusion and there was no agreement on a common method to watch over potential fabrication errors. lastly, the Americans were baffled by German's approach to intellectual property, with their more open collabortation praftices while the Germans kept everything as tightly as possible between firms and trade secrets. Too much was just blocked from American eyes and for the latter, manufacturing was somewhat done "in the blind". The Germans at any level as well pushed aggressively for the use of their own products and solution.

Lastly, in the US it was the Pentagon that footed expenses for the bulk of R&D (so taxpayer money) so that the government, like in WW2 kept complete ownership of the result, whereas each German firms, albeit financed by the Bundestag for R&D, retained all the rights to their design. It was impossible to these companies to share anything between them, and with US firms, despite great incentives. Eventually General Dolvin stepped down in October 1966, preferring to command an armored division. The program was considered afloat though when Major General Edwin H. Burba took over. But schedule was slipping. The design was finalized in 1965,; but now costs on USS side already spiralled to $138 million and a projection for production greenlight in 1968 shows now $303 million. This triggered interest from the Congress...

Programmatic complexity, growing costs led eventually the German Government, convinced by its own firm, that this joint project was going nowhere, and if any, was detrimental to German interests. At some point in 1965, whereas the Leopard I entered service and proved an excellent design, even believed to be the world's best, these design differences between teams fuelled more debates. gherman dnegineers saw the US propose for an unconventional and unproven American engine as well as the proposed 6 inches gun/launcher oddities that would add trmendous risk, add delays, complications and costs overruns. Germany wanted a simpler MBT, at worst an improve version of the Leopard.

The 152 mm/6 inches dual purpose cannon, something in development for the light tank M551 Sheridan was believed to add only marginal gains in accuracy at ranges beyond 2000 meters and worse at lower ranges. When the US insisted on non-metric fasteners, it was believed as an unnecessary compromise. In 1965, Germany showed signs of disinterest already, by reduced its financial commitment. In 1969 the program was now seen as an embarassement for the Bundeswehr and the press, backed by the industrials, advocated by a withdrawal as soon as possible. Involvement was reduced by all posssible measures, notably by emptying the Detroit office presence. What was left in the us was at best a "skeleton crew". Meanwhile the Bundeswher still nominally made an order for 500 KPz-70 to start ideally in 1969 and now was dicussing cancellation, with always the German consortium reassuring that a "B" plan was almost ready as a substitute tank.

On the US side there was stiull hope, notably from General Creighton Abrams, that an amicable end to this involvement could be found. General Burba then was succeeded by Brigadier General Bernard R. Luczak by mid-1968 and he quickly recoignised this partnership was clearly a failure, going nowhere. Luczak and Deputy Secretary David Packard wrote an agreement to end the partnership in January 1970, promptly accepted in Bonn.

The turret was also in shape and size, a radical departure over previous designs. Entirely welded it was massive in proportion to the hull, almost 3/4 of its size without the gun. The three men team was basically in a "cell" formed by the pannier. The driver was not separated from the rest of the crew by a lot. despite its size, the turret was jam-packed, with a forward section dedicated to the main gun and autoloader, coaxial MG, a central section for the crew, driver on one side and commander and gunner seated in tandem at the same level, and a rear section occupied by the bulkheaded ammunition storage. There was no cookoff blow-off doors however.

The outer armour layer was an US product, the new "High Performance Armour" which contained 9% of nickel and 4% of cobalt (extremely rare and costly), produced by vacuum arc remelting and heat treated at 500 BHN, to create plates 40 mm thick. It wa sbelieved proof against HEAT munitions but not kinetic munitions (for this only active protection could do). At this stage it was still 1st gen armour, without composites or extra modularity.

There were two fire proof armored transverse bulkheads separating the crew from multi-ply rubber fuel tank in the front compartment (not common) and engine compartment in the rear. Still, a fire extinguisher was also planned. Aluminum was used for the engine compartment floor to save weight despite its fire hazard, as well as for access doors on the engine deck. Their position was believed to be less sensitive. In addition to NBC there was a system for protecting the crew and equipments from electromagnetic pulses resulting od a nuclear explosion.

The low silhouette in addition to the direct protection offered by the armout was an enormous advantage as the tank could be lowered as much as 1.99 metres (6 ft 6 in), in fact better than on the Leopard 1. There was also some indirect, active protection in the shape of eight XM176 smoke grenade dischargers, two rows either side of the turret throwing two smoke grenades each, a combined AN-M8 HC and M34 WP (so 16 grenades), at commander's orders.

The teams diverged in the choice of the engine, quite industrially senstive by having two powerplants in respective versions, the new Continental AVCR air-cooled V-12 diesel rated for 1,470 horsepower (1,100 kW) on the US MBT-70 and German Daimler-Benz and then new MTU 1,500 hp (1,100 kW) which was tailored for quick change along the drive train and transmission in a mere 15 minutes. Top speed in both cases was a fantastic 43 miles per hour (69 km/h). At the time, the T-62 was capable of 31.06 miles per hour (49.99 km/h). But with twice the output for 45 tonnes expected, this was not surprising. Many argued that or the sake of keeping the tracks aligned, the engine needed to be governed.

Both sides used the same transmission, the German Renk electro-hydraulic transmission HSWL 354/2, with hydraulically operated gearbox,4 gear, 2 reverse while on the US side it was modified to procure all four speeds forward and backwards. The top speed was governed 50 kilometres per hour (31 mph) after the final choice of a Avco-Lycoming AGT-1500 gas turbine in 1969 on the US side, whereas the previous Continental Motors AVCR-1100 diesel provided 29.2 hp/t on the US MBT-70 and the Daimler-Benz/MTU MB 873 Ka-500 four-stroke diesel (larger and heavier) was provided a ratio of 29.8 hp/t on the KPz-70. Fuel capacity was 1,300 litres (343 gallons) for an operational range of 644 km (400 miles) initially, and with the turbine it was severely reduced, whereas the top speed jumped to 68.7 km/h (42.7 mph). its easy to recoignise what would become the XM1 Abrams here. The German version was even more impressive with 72 kilometres (45 mi) top speed but 580 kilometres (360 mi) range.

In trials started in 1965, the MBT-70 showed amazing performances, with configurations tested across one prototype with mild steel, and six pilots for both countries (so 12 total +2 prototypes). The pilots had hardened, final hulls to simulate weight, and were basically extra hulls that could be modified at will. The mild steel prototype were devoid of any armament but received a turret and loads equivalent of their equipments. Still, they showed the most impressive speed bursts with three times the acceleration of previous models. Closing to 75 kph was like a return to the days of Walter Christie in the 1920s...

In any case, they left any existing tank in the dust, especially the lumbering M48/60s, which now looked and felt extremely outdated compared to the sleek and fast MBT-70. That speed was definitel in the new mood that prophetized that armour was now irremediably defeated by new ammunition and only speed could radically reduce the tank time exposed to fire. using the existing optical sights at the time, it was extremely hard to cautch one of these new MBTs in scope. Demonstration in Germany impressed all present, and the MoD decided to push all M48 out in 1972.

There was however an issue, and this was -expectedly- with the very unusual turret driver cupola. Despite being close to the center of gravity, drivers complained of disorientation and this adversely impacted their performances, so much so that MBT-70 seemed to act like drunken boats. There was not immediate "fix", the entire turret needed to be redesigned and the perfect axial position only possible if the main gun was placed offset in the turret, which compromise its protection design and balance overall. At last, all the fixes and additions until 1969 understandably led from 45 tonnes to 54 tonnes (53 long tons; 60 short tons) and thus, that a new, dedicated line of armored recovery vehicles and bridge-launching systems was now needed, something the US side abhorred. Germany was more concerned by this extra weight, given the numerous, old bridges in existence in the country. Nobody had worked out amphibious aspects (crossing a deep river) even with preparation. The suggestion to delete the NBC protection was not to stand.

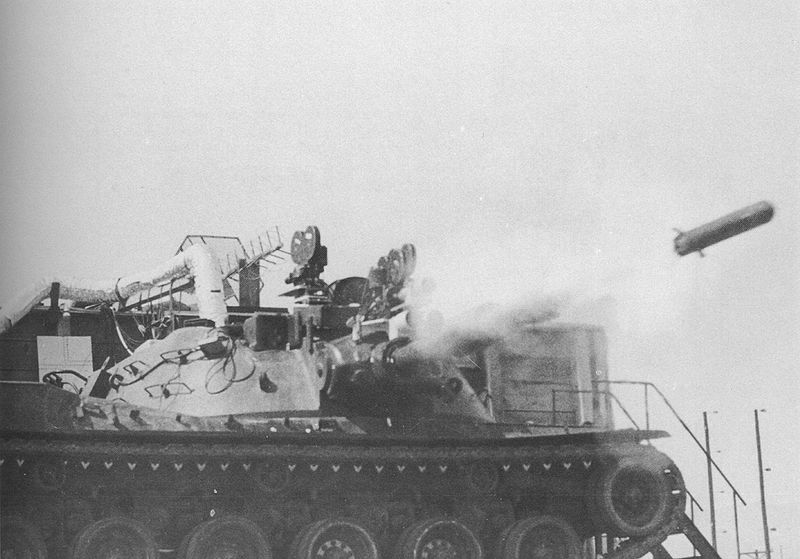

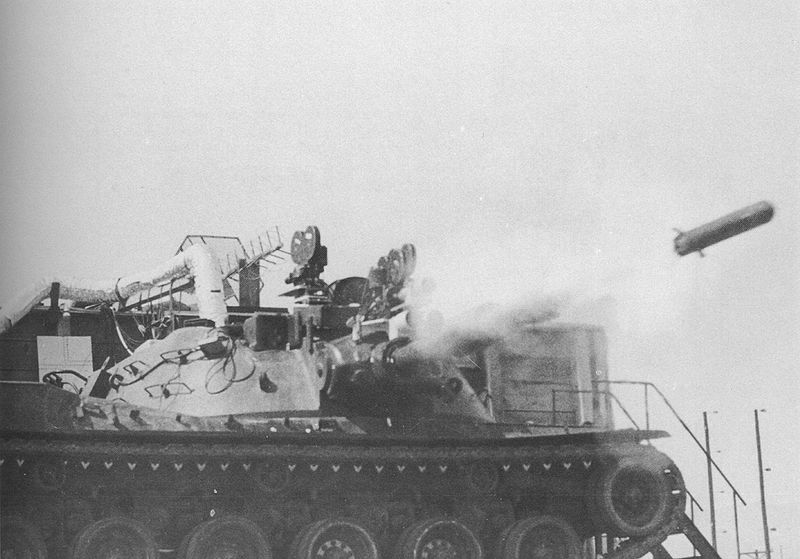

MBT-70 prototype test firing an MGM-51 missile The main armament was equally innovative and pushed by the US. The German side wanted an upgrade, but more conservative such as the new 120 mm developed in Britain for the replacement for the centurion. The US already developed and new and promising (to their eyes) relatively lower velocity, smoothbore and fully stabilized XM150 152 mm gun/launcher. The base taken was the XM-81 gun/launcher of the M551 Sheridan and M60A2 "Starship" which was stretched and improved, reinforced.

There was not doubt about the potenty of conventional 152 mm HE rounds as well as anti-personnel, but the M409A1 High Explosive Anti-Tank (HEAT) wa salso developed for it as well as the XM578E1 Armor-piercing fin-stabilized discarding sabot (APFSDS) round that artificially augmented velocity. The gun could also fire the Beehive anti-personnel rounds. But certainly the most prized item when used as a lower-velocity projector, the MGM-51 Shillelagh missile, with a combat range of 3,000 metres (9,800 ft) and optically guided.

Back to the XM578 APFSDS and it used a new tungsten alloy, 97.5 percent tungsten for a density of 18.5 g/cm³, and max impact expected. The other elephant on the room was the insternal space (or lack thereof) for spent cases. Ejection seemd odbvious but the constrains of internal space were such that no satisfying solution could be found. So instead, the tank rounds were developed with fylly combustible cases. This implied hoever an ever better gun and turret ventilation system.

The MBT-70 for precision was equipped by a then new and futuristic laser rangefinder as well as a 26-round auto-loader in the turret bustle, eliminating the loader and reducing the crew to three. The auto-loader was not new on the Soviet side as it was now becoming the norm. However it was on NATO's side, notably for maintenance teamwork and other concerns. The autoloader was developed so to be able to load both missiles and combustible-case tank rounds in one go. Rheinmetal presented its autoloader, but it was prone to deforming the combustible cases and caused jammings.

Instead, the US team proposed the General Motors design increasing ammunition capacity to 48 rounds. Italy, also interested by the new tank contributed to the XM-150 gun by its own automatic loading system from OTO Melara. It had a vertical rotating magazine and a barillet of 16 containers, for 5 types of ammunition, making it possible to fire 12 rounds a minute. Still, the XM150 gun/launcher had serious problems, which were not easy to fix and contributed greatly to the loss of faith on the German side into the project. It was also discovered that the caseless ammunition too vulnerable to water, expanding and jamming the barrel anymore or leaving hard residues after fire. In addition the same rounds tended to cookoff prematurely with build-up from previous fired rounds. There was also the issue of firing the missile and behind one of these rounds. The only obvious solution was to lower the rate of fire by half or less.

In total, despite its compact size and low silhouette, the space freed by the loader was now taken, around the autoloader, by forty six 152 mm rounds (Rheinmetal) or 48 (GM) whereas the OTO melara modified XM803 could carry 50. The Rheinmetall loader however had 26 ready rounds, twenty more in two compartments in rear hull bulkheaded stowage, twelve behind the driver's capsule. The Bundeswher was still unsure how to use this firepower at the time, and wanted a tactical combo with the Keiler and its Rheinmetall 120 mm smoothbore until the Keiler was merged with the MBT-70 chassis to create the Eber (wooden mock-up). The MBT-70 was to be the long range killer, mostly using its six missiles and APFSDS, breaking enemy tanks formations that could be then dealt peacemeal by the Keiler under 2,000 metres (6,600 ft).

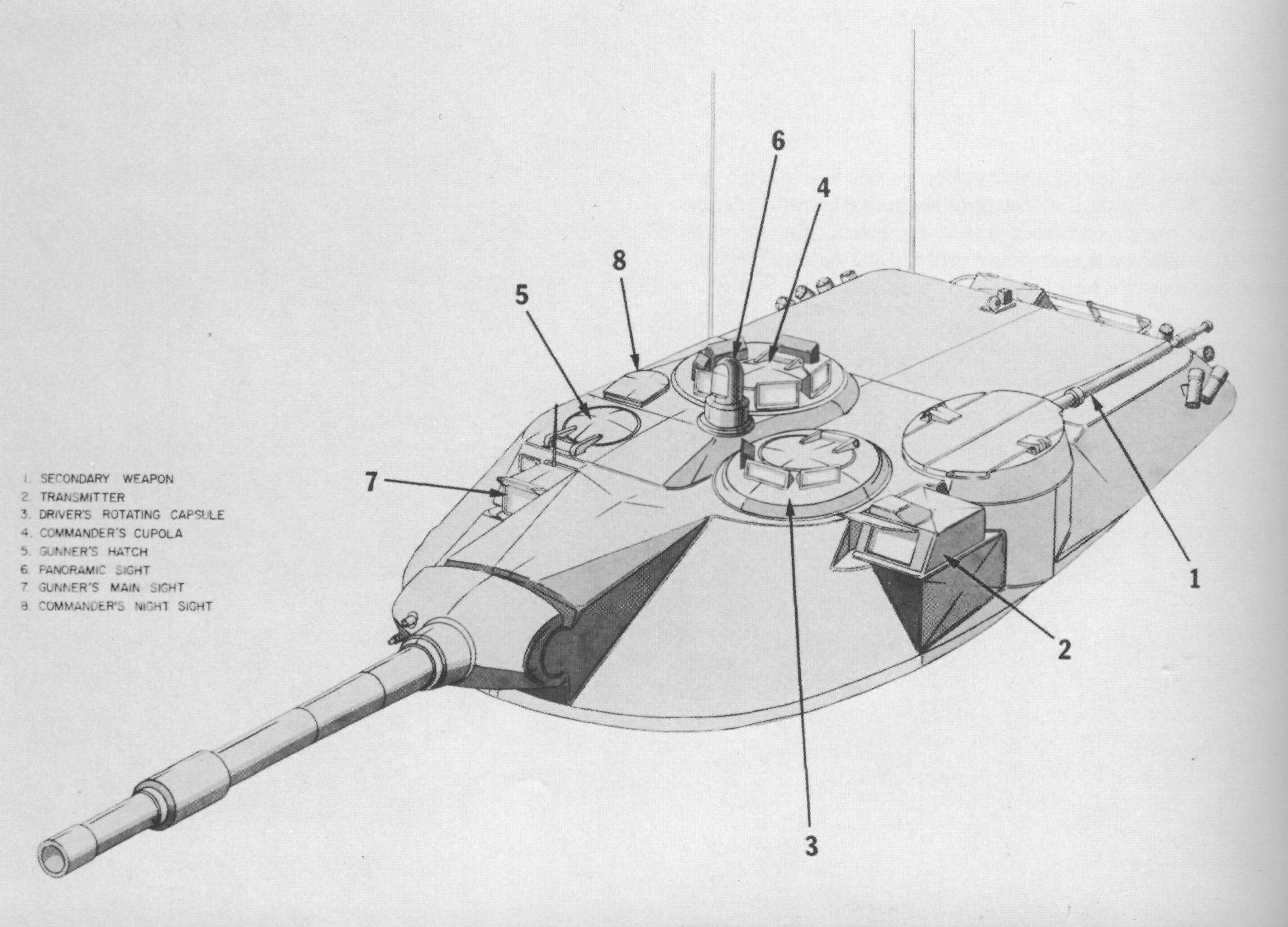

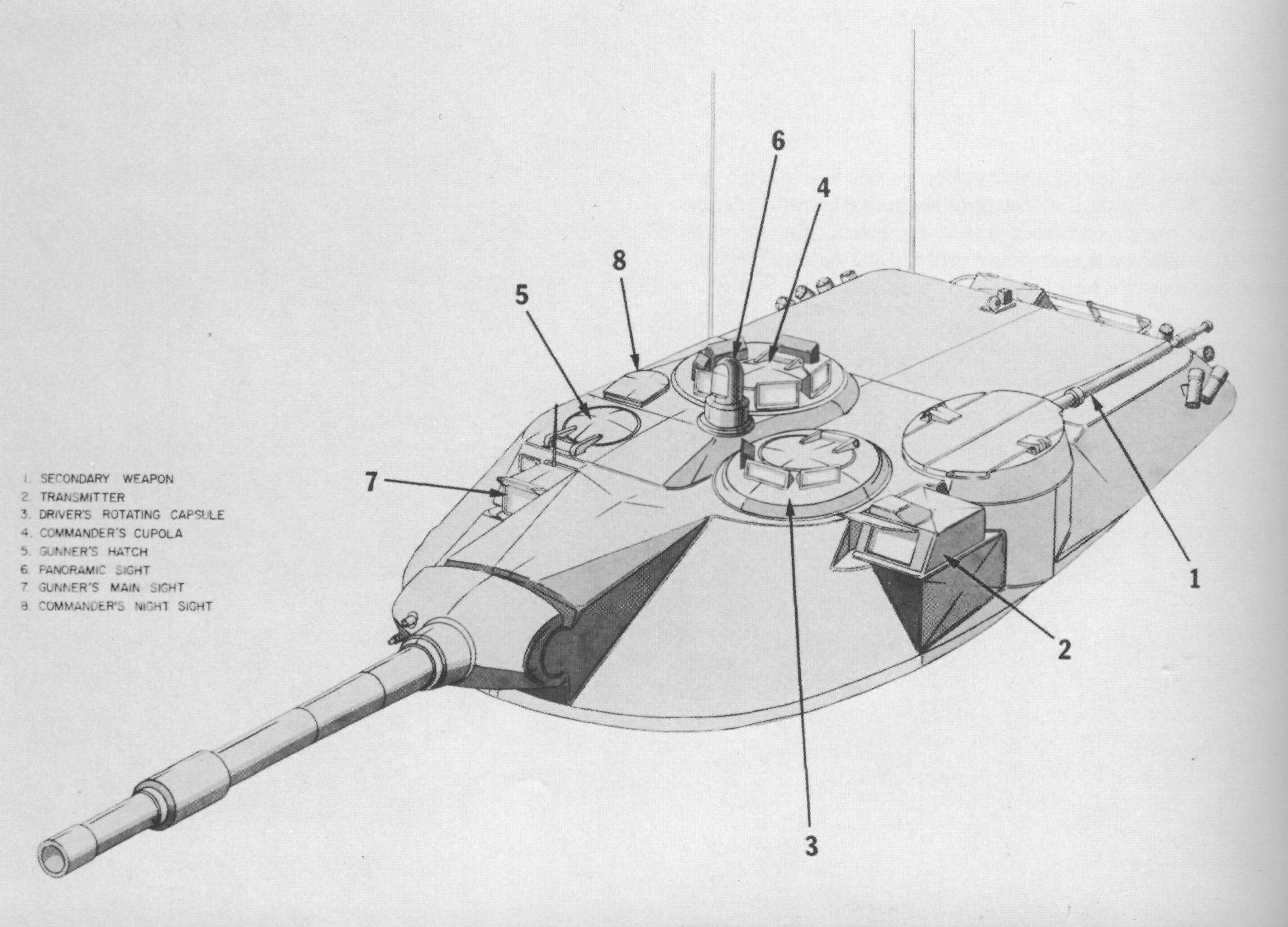

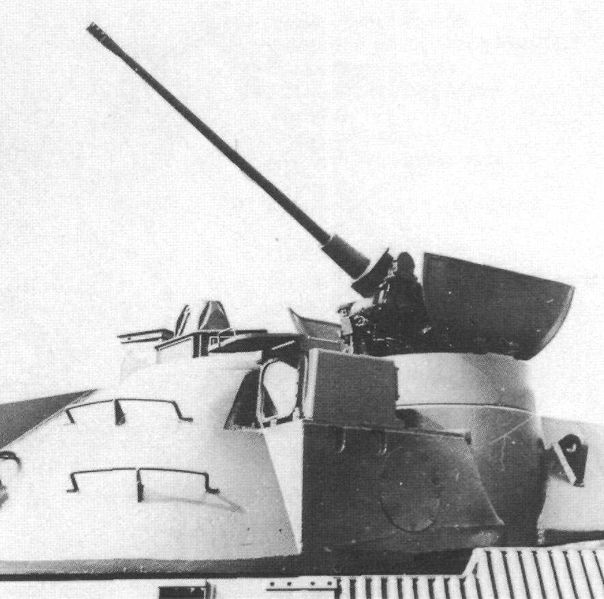

The secondary armament was a German proposal, a popular idea at the time to deal with lighter vehicles, troops and aircraft low flying, but not as helicopters as it was not seemed yet a new threat for tanks. This was a remote-controlled 20 mm Rh 202 autocannon with 660-750 rounds that can retracted into a container behind the driver's rotating cupola, operated remotely or directly if needed. The third stage was a classic, coaxial 7.62 mm alongside the main gun. The US chose the M73, the German went for the MG 3 (2,700 standard NATO rounds in both cases). However in practice the remote system and in general the whole mount for the 20 mm proved overengineerd and overcomplicated. On the US side it was criticized as finnicky and hard to maintain.

Deputy Secretary of Defense David Packard withhold $25 million for the production of six prototypes,waiting for the DoD to complete a review and ultimately Army leaders affirmed the MBT-70 was "technically sound" and that time and money would be saved by ending cooperation. In January 1970, the DoD made that partnership with Germany officially closed. Both countries were not poised to complete their own designs. It was of course more epensive on the US side ($305.4 million including the XM803 program), Germany stil pouring in $100 million and converting the "Keiler" into the Leopard 2, mixing aspects of both the Kfp.70 and Keiler. The 14 vehicles did not all survived.

On the US side, the next step, the XM-803 or "austere" variant of the MBT-70 was expected to cost no more than 500 ot 600k dollars and notably by using a less expensive armour. It was worked out by General Motors received from July 1971 when a new constract was signed, with the new XM150E6 gun coupled with a simplified autloader but 50 rounds, 20 mm gun replaced by a Browning 0.5 in M85, Continental AVCR-1100-3B engine derated to 1,250 horsepower (930 kW) at 2600 rpm, coupled with a GM XHM-1500-2B transmission and simplified National Water Lift hydropneumatic suspension. It was the installation of a gas-turbine AGT-1500 that led to the next XM-1. The XM803 was terminated after another audit in December 1971.

The MBT-70 still generated variants such as the proposed XM742 Recovery Vehicle, XM743 bridge layer (XM744 double-folding bridge), XM745 Combat Engineer Vehicle with a 165 mm demolition gun, 25 mm autocannon. The Bundeswehr proposed a tank hunter with two main guns, the VT 1-1, as a shortened KPz 70 chassis. Surviving vehicles comprises a prototype at the Anniston Army Depot (Alabama), another plus a XM803 at the Armor Museum Restoration Yard at Fort Moore (Georgia), and in Germany one at the Deutsches Panzermuseum Munster and another Kpz-70 at the Wehrtechnische Studiensammlung Koblenz.

This program met many challenges from the start from communication to coordination and eventually industrial disputes between US and West German teams. Diverging requirements never aligned and were left unresolved while the project advanced too far to be revised, with spiralling costs. West Germany withdrew from the project in 1969 but the US prersevered with the MBT-70 until 1971 until cancelling it and reorienting the teams and funds to the XM1 Abrams. West Germany started anew and developed the Leopard 2.

Cutaway of the MBT-70

Origins: MacNamaras's admiration for German engineering

The joint main battle tank program was proposed by US Secretary of Defense Robert McNamara in order to fill several objectives. The "Whiz Kid" at Ford Motor Company (later president) was fascinating by German engineering and shepherded development of the Ford Cardinal (cancelled compact family car from both countries). The main objective there was to reduce development costs. This industrial management was then shifted to military production in all three branches during his stay as secretary. Apart cost savings and taking the best engineering of both countries, the other obvious obective was to provide the US a way to cope with the T-62 and then in development T-64 and T-72, 2nd generation Soviet MBTs.The third objective was more global. NATO member states at the time had a disjointed park of heteroclitous tanks and armoured vehicles, lacking common ammunition, fuel and parts, a nightmare of logistics if war broke out. Joint programmes were rare, although a political push for it, and this also included tanks. Up to that time one of the most famous failure was the Europanzer. Both countries poartes they ways and created the AMX-30 and leopard I, both widely exported.

But while the career of the Leopard I was hust getting started, West Germany still used American M48 Pattons, and was now moving on full domestic designs. McNamara regarded Germany as a more and more important and central member of NATO, believing that a joint development, backed by the might of US indistrial output, with a project infused with German tech, could provide NATO members and allies outside NATO a solid, universal main battle tank up to the challenge and at a much lower cost. Covering both West German and US needs already allowed to keep the cost lower than competitive purely national programs, at least on paper, and with prospects of exports (and perhaps even some purchases from Britain and France), statistics looked even sexier.

In 1961 (for context the Europanzer program was just getting started) McNamara approached German Minister of Defence Franz Josef Strauss starting a collaborative main battle tank program. But instead the latter suggested the U.S. should instead directly buy the Leopard 1 then in development... Strauss however agree to a common component program to lower costs. McNamara accepted but continued to lobby for a larger tank program cooperation and succeeded with a tentative agreement with West Germany in 1962.

Meawnile the US Armor Branch pressed the Pentagon to finance a successor to the M60 Patton, seen merely as an improved M48, a technology which traced its lineage back to the Pershing heavy tank. But McNamara's long (seven-year) timeline did not met senior armor officer's demands while others questioned McNamara's fascination of German engineering adn that it was not on par with its level in 1944, while struggling to keep pace with innovations or lack of financing. Some thougfht this would be a risky, net technology transfer towards Germany, alsways in risk of falling overnight to a Soviet attack, while the UK would make a better partner. France under De Gaulle was of course out of question. McNamara instead argues the country's excellent economic wealth, dynamic industrial sector as prven by its successful post-war "economic miracle" and the best placed in Europe to commit to a such a project.

The issue was to agree on a common program that could meet the requirements of both armies. So in August 1963, Germany and the United States signed a memorandum of understanding specifying certain desired characteristics. A Joint Engineering Agency was created as well as a Joint Design Team with 50% representation on both sides. But soon, differing engineering practices started to undermine the project, and this went on until the end.

Development History

Turret design In 1963, General Welborn G. Dolvin (former tank commander) was chosen as project manager, at the head of the US team and three contractors were soon in the loop, Chrysler Defense, General Motors and Ford/FMC joint venture. General Dolvin trusted GM more to bring fresh ideas instead of Chrysler tbat for too long had been living on the "rent" of producing US tanks. In Germany, a Development Corporation was formed with several German firms, including those that would later be part of Rheinmetall and Krauss Maffei Wegman. In first phase, GM engineers flew to Augsburg to work with German engineers, but to manage them, and in a second phase, it would be the reverse, to streamline practices, at GM's factories in Detroit.

But disputes soon arose over every element of the design and the use of metric and SAE units plagues communication and augmented chances of incompatibility. These were found in many shared manufactured components, which repartition to the two countries proved delicate. These constant disagreement went to the ear of to McNamara and MoD Kai-Uwe von Hassel. They ultimately failed to force the use of a common measurement system and so both side stuck to their own preferred measurement, applied to the parts they designed and produced. Common metric became however standard in all interface connections and welding parts.

But extra complexity created delays in development timetable. Of course the budget ros as well quickly. Different methods of projection in production, even the way the blueprints were laid out cause extra confusion and there was no agreement on a common method to watch over potential fabrication errors. lastly, the Americans were baffled by German's approach to intellectual property, with their more open collabortation praftices while the Germans kept everything as tightly as possible between firms and trade secrets. Too much was just blocked from American eyes and for the latter, manufacturing was somewhat done "in the blind". The Germans at any level as well pushed aggressively for the use of their own products and solution.

Lastly, in the US it was the Pentagon that footed expenses for the bulk of R&D (so taxpayer money) so that the government, like in WW2 kept complete ownership of the result, whereas each German firms, albeit financed by the Bundestag for R&D, retained all the rights to their design. It was impossible to these companies to share anything between them, and with US firms, despite great incentives. Eventually General Dolvin stepped down in October 1966, preferring to command an armored division. The program was considered afloat though when Major General Edwin H. Burba took over. But schedule was slipping. The design was finalized in 1965,; but now costs on USS side already spiralled to $138 million and a projection for production greenlight in 1968 shows now $303 million. This triggered interest from the Congress...

Programmatic complexity, growing costs led eventually the German Government, convinced by its own firm, that this joint project was going nowhere, and if any, was detrimental to German interests. At some point in 1965, whereas the Leopard I entered service and proved an excellent design, even believed to be the world's best, these design differences between teams fuelled more debates. gherman dnegineers saw the US propose for an unconventional and unproven American engine as well as the proposed 6 inches gun/launcher oddities that would add trmendous risk, add delays, complications and costs overruns. Germany wanted a simpler MBT, at worst an improve version of the Leopard.

The 152 mm/6 inches dual purpose cannon, something in development for the light tank M551 Sheridan was believed to add only marginal gains in accuracy at ranges beyond 2000 meters and worse at lower ranges. When the US insisted on non-metric fasteners, it was believed as an unnecessary compromise. In 1965, Germany showed signs of disinterest already, by reduced its financial commitment. In 1969 the program was now seen as an embarassement for the Bundeswehr and the press, backed by the industrials, advocated by a withdrawal as soon as possible. Involvement was reduced by all posssible measures, notably by emptying the Detroit office presence. What was left in the us was at best a "skeleton crew". Meanwhile the Bundeswher still nominally made an order for 500 KPz-70 to start ideally in 1969 and now was dicussing cancellation, with always the German consortium reassuring that a "B" plan was almost ready as a substitute tank.

On the US side there was stiull hope, notably from General Creighton Abrams, that an amicable end to this involvement could be found. General Burba then was succeeded by Brigadier General Bernard R. Luczak by mid-1968 and he quickly recoignised this partnership was clearly a failure, going nowhere. Luczak and Deputy Secretary David Packard wrote an agreement to end the partnership in January 1970, promptly accepted in Bonn.

Design

Hull

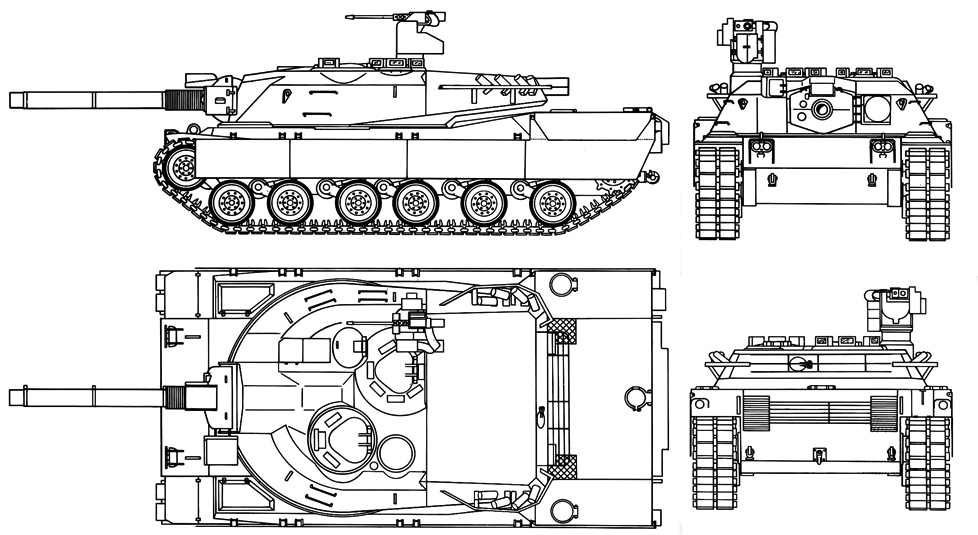

The MBT-70 most stringent demand was a low silhouette as the tall M48/60 were criticized as "towering", making them easy picks. The MBT-70 and its suspension system, but also its brand new hull shape and the choice of locating the engine and transmission made it compact, and just over 6 feet (1.8 m) from the floor to the turret-roof. The immdate problem with this decision was to negate the driver's location entirely, leading to a very radical choice, relocating the driver into the turret, inside a cupola rotating independntly from the turret so to always face forward. There was also the possibility to spin the cupola around in order to drive backwards in direct vision, something previously impossible.The turret was also in shape and size, a radical departure over previous designs. Entirely welded it was massive in proportion to the hull, almost 3/4 of its size without the gun. The three men team was basically in a "cell" formed by the pannier. The driver was not separated from the rest of the crew by a lot. despite its size, the turret was jam-packed, with a forward section dedicated to the main gun and autoloader, coaxial MG, a central section for the crew, driver on one side and commander and gunner seated in tandem at the same level, and a rear section occupied by the bulkheaded ammunition storage. There was no cookoff blow-off doors however.

Protection

The frontal area had spaced armor, with two layers spaced with 127mm (5 inches), with the inner layer being a softer steel repalcing the classic spall liner over 46mm (1.18 in) and the outer layer made of harder cold-rolled steel 34mm (1.3 in). NBC was also planned from the start, with provision made for the installation of a polyethylene radiation shielding taunted to shield the crew at 20:1 against neutron radiation.The outer armour layer was an US product, the new "High Performance Armour" which contained 9% of nickel and 4% of cobalt (extremely rare and costly), produced by vacuum arc remelting and heat treated at 500 BHN, to create plates 40 mm thick. It wa sbelieved proof against HEAT munitions but not kinetic munitions (for this only active protection could do). At this stage it was still 1st gen armour, without composites or extra modularity.

There were two fire proof armored transverse bulkheads separating the crew from multi-ply rubber fuel tank in the front compartment (not common) and engine compartment in the rear. Still, a fire extinguisher was also planned. Aluminum was used for the engine compartment floor to save weight despite its fire hazard, as well as for access doors on the engine deck. Their position was believed to be less sensitive. In addition to NBC there was a system for protecting the crew and equipments from electromagnetic pulses resulting od a nuclear explosion.

The low silhouette in addition to the direct protection offered by the armout was an enormous advantage as the tank could be lowered as much as 1.99 metres (6 ft 6 in), in fact better than on the Leopard 1. There was also some indirect, active protection in the shape of eight XM176 smoke grenade dischargers, two rows either side of the turret throwing two smoke grenades each, a combined AN-M8 HC and M34 WP (so 16 grenades), at commander's orders.

Mobility

Many features of the MBT-70 were pushing the boundaries of tank design, like the engine and an advanced hydropneumatic suspension system for unheard of cross-country speeds for 45 tonnes (50 short tons). The suspension could be raised or lowered by the driver and enabled the perfect hull-down waiting or ambush position. The entiure hull vould be lowered down to 4 inches (100 mm) from the ground or 28 inches (710 mm) over rough terrain.The teams diverged in the choice of the engine, quite industrially senstive by having two powerplants in respective versions, the new Continental AVCR air-cooled V-12 diesel rated for 1,470 horsepower (1,100 kW) on the US MBT-70 and German Daimler-Benz and then new MTU 1,500 hp (1,100 kW) which was tailored for quick change along the drive train and transmission in a mere 15 minutes. Top speed in both cases was a fantastic 43 miles per hour (69 km/h). At the time, the T-62 was capable of 31.06 miles per hour (49.99 km/h). But with twice the output for 45 tonnes expected, this was not surprising. Many argued that or the sake of keeping the tracks aligned, the engine needed to be governed.

Both sides used the same transmission, the German Renk electro-hydraulic transmission HSWL 354/2, with hydraulically operated gearbox,4 gear, 2 reverse while on the US side it was modified to procure all four speeds forward and backwards. The top speed was governed 50 kilometres per hour (31 mph) after the final choice of a Avco-Lycoming AGT-1500 gas turbine in 1969 on the US side, whereas the previous Continental Motors AVCR-1100 diesel provided 29.2 hp/t on the US MBT-70 and the Daimler-Benz/MTU MB 873 Ka-500 four-stroke diesel (larger and heavier) was provided a ratio of 29.8 hp/t on the KPz-70. Fuel capacity was 1,300 litres (343 gallons) for an operational range of 644 km (400 miles) initially, and with the turbine it was severely reduced, whereas the top speed jumped to 68.7 km/h (42.7 mph). its easy to recoignise what would become the XM1 Abrams here. The German version was even more impressive with 72 kilometres (45 mi) top speed but 580 kilometres (360 mi) range.

In trials started in 1965, the MBT-70 showed amazing performances, with configurations tested across one prototype with mild steel, and six pilots for both countries (so 12 total +2 prototypes). The pilots had hardened, final hulls to simulate weight, and were basically extra hulls that could be modified at will. The mild steel prototype were devoid of any armament but received a turret and loads equivalent of their equipments. Still, they showed the most impressive speed bursts with three times the acceleration of previous models. Closing to 75 kph was like a return to the days of Walter Christie in the 1920s...

In any case, they left any existing tank in the dust, especially the lumbering M48/60s, which now looked and felt extremely outdated compared to the sleek and fast MBT-70. That speed was definitel in the new mood that prophetized that armour was now irremediably defeated by new ammunition and only speed could radically reduce the tank time exposed to fire. using the existing optical sights at the time, it was extremely hard to cautch one of these new MBTs in scope. Demonstration in Germany impressed all present, and the MoD decided to push all M48 out in 1972.

There was however an issue, and this was -expectedly- with the very unusual turret driver cupola. Despite being close to the center of gravity, drivers complained of disorientation and this adversely impacted their performances, so much so that MBT-70 seemed to act like drunken boats. There was not immediate "fix", the entire turret needed to be redesigned and the perfect axial position only possible if the main gun was placed offset in the turret, which compromise its protection design and balance overall. At last, all the fixes and additions until 1969 understandably led from 45 tonnes to 54 tonnes (53 long tons; 60 short tons) and thus, that a new, dedicated line of armored recovery vehicles and bridge-launching systems was now needed, something the US side abhorred. Germany was more concerned by this extra weight, given the numerous, old bridges in existence in the country. Nobody had worked out amphibious aspects (crossing a deep river) even with preparation. The suggestion to delete the NBC protection was not to stand.

Armament

MBT-70 prototype test firing an MGM-51 missile The main armament was equally innovative and pushed by the US. The German side wanted an upgrade, but more conservative such as the new 120 mm developed in Britain for the replacement for the centurion. The US already developed and new and promising (to their eyes) relatively lower velocity, smoothbore and fully stabilized XM150 152 mm gun/launcher. The base taken was the XM-81 gun/launcher of the M551 Sheridan and M60A2 "Starship" which was stretched and improved, reinforced.

There was not doubt about the potenty of conventional 152 mm HE rounds as well as anti-personnel, but the M409A1 High Explosive Anti-Tank (HEAT) wa salso developed for it as well as the XM578E1 Armor-piercing fin-stabilized discarding sabot (APFSDS) round that artificially augmented velocity. The gun could also fire the Beehive anti-personnel rounds. But certainly the most prized item when used as a lower-velocity projector, the MGM-51 Shillelagh missile, with a combat range of 3,000 metres (9,800 ft) and optically guided.

Back to the XM578 APFSDS and it used a new tungsten alloy, 97.5 percent tungsten for a density of 18.5 g/cm³, and max impact expected. The other elephant on the room was the insternal space (or lack thereof) for spent cases. Ejection seemd odbvious but the constrains of internal space were such that no satisfying solution could be found. So instead, the tank rounds were developed with fylly combustible cases. This implied hoever an ever better gun and turret ventilation system.

The MBT-70 for precision was equipped by a then new and futuristic laser rangefinder as well as a 26-round auto-loader in the turret bustle, eliminating the loader and reducing the crew to three. The auto-loader was not new on the Soviet side as it was now becoming the norm. However it was on NATO's side, notably for maintenance teamwork and other concerns. The autoloader was developed so to be able to load both missiles and combustible-case tank rounds in one go. Rheinmetal presented its autoloader, but it was prone to deforming the combustible cases and caused jammings.

Instead, the US team proposed the General Motors design increasing ammunition capacity to 48 rounds. Italy, also interested by the new tank contributed to the XM-150 gun by its own automatic loading system from OTO Melara. It had a vertical rotating magazine and a barillet of 16 containers, for 5 types of ammunition, making it possible to fire 12 rounds a minute. Still, the XM150 gun/launcher had serious problems, which were not easy to fix and contributed greatly to the loss of faith on the German side into the project. It was also discovered that the caseless ammunition too vulnerable to water, expanding and jamming the barrel anymore or leaving hard residues after fire. In addition the same rounds tended to cookoff prematurely with build-up from previous fired rounds. There was also the issue of firing the missile and behind one of these rounds. The only obvious solution was to lower the rate of fire by half or less.

In total, despite its compact size and low silhouette, the space freed by the loader was now taken, around the autoloader, by forty six 152 mm rounds (Rheinmetal) or 48 (GM) whereas the OTO melara modified XM803 could carry 50. The Rheinmetall loader however had 26 ready rounds, twenty more in two compartments in rear hull bulkheaded stowage, twelve behind the driver's capsule. The Bundeswher was still unsure how to use this firepower at the time, and wanted a tactical combo with the Keiler and its Rheinmetall 120 mm smoothbore until the Keiler was merged with the MBT-70 chassis to create the Eber (wooden mock-up). The MBT-70 was to be the long range killer, mostly using its six missiles and APFSDS, breaking enemy tanks formations that could be then dealt peacemeal by the Keiler under 2,000 metres (6,600 ft).

The secondary armament was a German proposal, a popular idea at the time to deal with lighter vehicles, troops and aircraft low flying, but not as helicopters as it was not seemed yet a new threat for tanks. This was a remote-controlled 20 mm Rh 202 autocannon with 660-750 rounds that can retracted into a container behind the driver's rotating cupola, operated remotely or directly if needed. The third stage was a classic, coaxial 7.62 mm alongside the main gun. The US chose the M73, the German went for the MG 3 (2,700 standard NATO rounds in both cases). However in practice the remote system and in general the whole mount for the 20 mm proved overengineerd and overcomplicated. On the US side it was criticized as finnicky and hard to maintain.

Production and Legacy

Mixing many innovative features (too much in fact) and degraded performances and issues not easy to solve, plus spiralling cost, weighted enough for Germany to part of the program, while the US maintained its trust, at least for a while. By 1969 the cost reached five times initial projections, at $1 million per vehicle or $80 million/292.8 million DM total in 1965 but $303 million (1.1 billion DM) in 1969 with West Germany's commitment of $130 million (475.8 million DM) was above and beyond all tolerated excesses for the Bundestag. Withdrawal was announced in April 1969 and also that it would now develop a new tank. In July a House Armed Services subcommittee pointed out the issues of the M551 Sheridan also linked the MBT-70 to it. In August 1969, Senator Thomas Eagleton was granted an independent audit and recommended the continue the program on a much more austere basis to cut costs.Deputy Secretary of Defense David Packard withhold $25 million for the production of six prototypes,waiting for the DoD to complete a review and ultimately Army leaders affirmed the MBT-70 was "technically sound" and that time and money would be saved by ending cooperation. In January 1970, the DoD made that partnership with Germany officially closed. Both countries were not poised to complete their own designs. It was of course more epensive on the US side ($305.4 million including the XM803 program), Germany stil pouring in $100 million and converting the "Keiler" into the Leopard 2, mixing aspects of both the Kfp.70 and Keiler. The 14 vehicles did not all survived.

On the US side, the next step, the XM-803 or "austere" variant of the MBT-70 was expected to cost no more than 500 ot 600k dollars and notably by using a less expensive armour. It was worked out by General Motors received from July 1971 when a new constract was signed, with the new XM150E6 gun coupled with a simplified autloader but 50 rounds, 20 mm gun replaced by a Browning 0.5 in M85, Continental AVCR-1100-3B engine derated to 1,250 horsepower (930 kW) at 2600 rpm, coupled with a GM XHM-1500-2B transmission and simplified National Water Lift hydropneumatic suspension. It was the installation of a gas-turbine AGT-1500 that led to the next XM-1. The XM803 was terminated after another audit in December 1971.

The MBT-70 still generated variants such as the proposed XM742 Recovery Vehicle, XM743 bridge layer (XM744 double-folding bridge), XM745 Combat Engineer Vehicle with a 165 mm demolition gun, 25 mm autocannon. The Bundeswehr proposed a tank hunter with two main guns, the VT 1-1, as a shortened KPz 70 chassis. Surviving vehicles comprises a prototype at the Anniston Army Depot (Alabama), another plus a XM803 at the Armor Museum Restoration Yard at Fort Moore (Georgia), and in Germany one at the Deutsches Panzermuseum Munster and another Kpz-70 at the Wehrtechnische Studiensammlung Koblenz.

MBT-70 specifications | ||

| Dimensions | 9.1 x 3.51 x 1.99-2.59 m metres (29 ft 10 in x 11 ft 6 in x 6 ft 6 in-8 ft 6 in) | |

| Weight | 50.4 tonnes (49.6 long tons; 55.6 short tons) | |

| Crew | 3 | |

| Propulsion | MBT-70: 1,470 horsepower (1,100 kW) KPz-70: 1,500 horsepower (1,100 kW) | |

| Suspension | Hydropneumatic | |

| Speed (road) | 68.7 km/h (42.7 mph) | |

| Range | 644 km (400 miles) | |

| Armament | 152 mm XM150E5, 20 mm Rh-202 auto, 7.62 mm M73/MG 3 coax | |

| Armor | Spaced armour, see notes | |

| Total production | 14 | |

Illustrations

MBT-70 pilot N°5 in 1968.

XM-803 in 1971.

Kampfpanzer 70, and its roof mounted 20mm Rheinmetall autocannon, rear twin-grenades smoke projectors rows.

Photos

More

Books

Else, Daniel H., III. (31 January 2008). Bias in Weapon Development (Dissertation). pp. 67–68.Hunnicutt, Richard Pearce (1990). Abrams - A History of the American Main Battle Tank. Presidio Press.

. Hunnicutt, Richard Pearce (2015) [1984]. Patton: A History of the American Main Battle Tank. Echo Point Books & Media.

McNaugher, Thomas L. (August 1981). Collaborative Development of Main Battle Tanks: Lessons from the U.S.–German Experience (PDF). The Rand Corporation (Report).

Links

militaryfactory.comBias in weapon development, Else, Daniel H., III. George Washington Univ.2008.

MBT-70 RAND report in 1981.

Plans and view of the tank

Procurement Lockheed Aircraft corporation

en.wikipedia.org

Video

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com