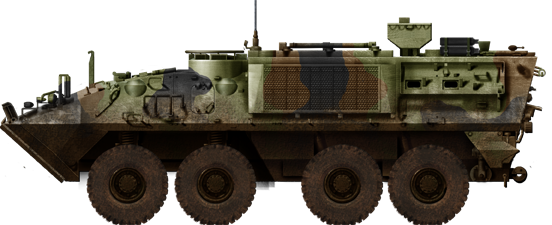

The Bison is a Canadian variant related to the American LAV-II produced by General motors, and itself a derivative of the Swiss MOWAG Piranha 8x8, one of the most successful western wheeled multirole vehicle of the last three decades. It was to replace the GDLS-Canada 6x6 family of Armoured Vehicle General Purpose (AVGP) Grizzly and Cougar of the seventies in a more dedicated, specialized package. The vehicle was accepted in 1990 and is still in service with the Canadian Armed Forces after a refit in the 2000s, partially replaced by the LAV-III, then the LAV-6 in this decade.

Program lead was Colonel Roméo Dallaire, Head of the Army's Armoured Vehicle Assessment and Procurement. He expressed the wish of his administration to purchase some 200 M113A3 (most recently upgraded variant) already well known and used by the Canadian Forces which still deployed thousands of M113A1s and M113A2s.

This included the manufacturing in the United States, completed in Canada with domestic parts to fit the conditions of the Canadian Forces procurement. However Diesel Division General Motors Canada (DDGM) at this time was going to end its order of LAV-25s for the United States Marine Corps. It was now facing the spectre of empty production lines at the Ontario Plant for a year or more, pushing personal to the street and loosing skills.

As often in that case, the solution was technical, industrial and political: With no new contract scheduled for 1990, considered shutting down the plant, local politicians and Muncie's Mayor confered with a small team of salesmen and engineers from GM. The latter were aware of the army program, and took their chance to earn the contract and contreive the US-specs LAV II chassis to fit the Canadian reserve requirement, with the added bonus of speed. They prepared an argumentation that the swap from a tracked to a wheeled platform would present many advantages, notably because the reservists usually spent a lot of time on roads within Canada, compounded with cheaper operation costs. Backed by local political support at Muncie willing to preserve jobs, their case was solid.

To convince Land Force Command, two engineers from DDGM made a design based on a small scale model of the LAV II chassis, removed the original troop compartment, added a large box on the rear half to increase internal capacity and replaced the former doors with a ramp similar similar to the one sported by the M113. This small scale model was shown to colonel Dallaire. But he was not interested in the proposal, and went on in his project on acquiring the M113A3, until DDGM decided to go above his head, playing its long embedded political contacts in 1988 and force the hand of the Canadian government. DDGM eventually won over the lower budget of the proposal Michael Wilson, the Minister of Finance, and several other members of Mobile Forces Command Headquarters based in Saint-Hubert, Quebec.

However, engineers and executives of DDGM continued to lobby Col. Dallaire to obtain the contract and decided to create a full-scale prototype for a presentation. DDGM brought it at the Canadian Forces Base Borden, unveiled under massive press coverage at the Armed Forces Day on June 5, 1988. Both Dallaire and Beatty were present. To gain time, working around the clock, engineers started with a battered tested LAV-25 used previously for airdroppings and modified the hull to fit the scale model.

In addition to making a new troop compartment, keeping the original suspension, drive-train and front half, they last task, most complicated, was to fit a working ramp, which they did under eight day. The turret ring was replaced with a large folding roof hatch, and the hull roof was assorted with a new raised commander cupola taken from existing stocks at the front left, behind the driver, a classic APC configuration. The bulgy rear part soon earned it the nickname "Bison", which was immediately marketed by DDGM. After being assembled, cleaned in and out, the prototype was painted anew, finished to show the internals, made ready to be shown.

The vehicle was driven up to CFB Borden and was presented during the parade on Armed Forces Day. The shown was considered a success, as DDGM staff invited Beatty to come on board and it seemingly won over his support. However Colonel Dallaire continued to support the M113A3 acquisition. DDGM then hired a top-end lobbyist to Ottawa, working out the existing arguments already presented to Beatty, notably on the cost-efficience and low maintenance, and speed. They also advanced the idea the Regular Force would made eventually the acquisition of new M113A3s. DDGM indeed seemingly new about the Regular Force likely reappropriation of the new vehicles for their own use.

In the end, it's the Army staff that went over the head of Colonel Dallaire and decided to purchase the Bison in July 1989. A firm order of 149 "Bison" armoured personnel carriers was passed, alongside 18 "Bison CP" command posts, and 16 "Wolf" 81 mm mortar carriers plus 16 "MRV Bison" (maintenance and recovery vehicles) making for a total of 199 vehicles. Production was setup already and finalized to start in early 1990, with the first rolling of the line in mid-1990 and procured.

The vehicle incorporates a rail mount system in the cargo and passenger compartment, making it mission-specific without any manufacturing, with kits provided to reserve units. The driver, like in the regular LAV-25, is seated in the front-left of the crew compartment, with the commander in a a slightly raised position, directly behind the driver. It had a specific access hatch and a ring-mounted machine gun. The engine was to the right of the crew compartment. The latter housed height infantry with her gear suspended or under them, with seating arrangements on rails allowed them to slide out through the large power operated ramp at the rear.

Bison in Afghanistan, 2000s

The Bison was soon deployed The Bison took part in the Oka Crisis (1990), Gulf War (1990-1991), United Nations Operation in Somalia II (1993-1995), Yugoslav Wars (1991-2001) and War in Afghanistan (2001–2021). Canadian Bison armored personnel carriers were gradually replaced by the newer LAV III armored vehicles. Part of these were refurbished and converted into support variants: Ambulances, recovery vehicles, electronic warfare vehicles, of the list given above in "modularity". The new variants also had an upgraded engines as as said above, fittings for extra add-on and BAR armor, and many other improvements.

Bison in Ukraine ? With the replacement of both the LAV-III and LAV-6 (gradually the next years) it's clear that the pool of the refusbished vehicles could be used in Ukraine, provided the Canadian Army is willing to put them in shape and that they are still in storage. Recently, the Canadian Government instead sent to the Ukrainian military its most recent LAV ACSV "Super Bison" wheeled armored vehicles. The latter are an the final version of the Canadian LAV-6, with 360 currently on order.

-Field ambulance

-Bison MRT, Mobile repair team vehicle

-Bison ARV or armoured recovery vehicle

-Airspace coordination centre vehicle (ACV)

-Bison EW (electronic warfare vehicle).

-Bison EV (engineer vehicle with tailored hydraulic tools)

-Bison NBCR (NBC reconnaissance vehicle version).

These are currently in service, pending replacement for the more modern sub-variants of the Canadian LAV-III, sharing many caractsristics with the late versions of the Stryker.

army-guide.com

wikipedia.org bison coyote

warwheels.net

military-today.com

canada.ca

dewengineering.com (Bison upgrades)

armyrecognition.com

wikipedia.org/wiki/General_Motors_LAV

GM Canada (General_Motors_Diesel) branch

canadianmilitaryhistory.ca

Canada's Mechanized Infantry: The Evolution of a Combat Arm, 1920–2012

Development

The Bison origin layed in the Land Force Command and publication of the 1987 Defence White Paper under the direction of the National Defence Minister Perrin Beatty. It came with the accouncement of major spending increases to support the Canadian Forces Reserves looking for a new armoured personnel carrier.Program lead was Colonel Roméo Dallaire, Head of the Army's Armoured Vehicle Assessment and Procurement. He expressed the wish of his administration to purchase some 200 M113A3 (most recently upgraded variant) already well known and used by the Canadian Forces which still deployed thousands of M113A1s and M113A2s.

This included the manufacturing in the United States, completed in Canada with domestic parts to fit the conditions of the Canadian Forces procurement. However Diesel Division General Motors Canada (DDGM) at this time was going to end its order of LAV-25s for the United States Marine Corps. It was now facing the spectre of empty production lines at the Ontario Plant for a year or more, pushing personal to the street and loosing skills.

As often in that case, the solution was technical, industrial and political: With no new contract scheduled for 1990, considered shutting down the plant, local politicians and Muncie's Mayor confered with a small team of salesmen and engineers from GM. The latter were aware of the army program, and took their chance to earn the contract and contreive the US-specs LAV II chassis to fit the Canadian reserve requirement, with the added bonus of speed. They prepared an argumentation that the swap from a tracked to a wheeled platform would present many advantages, notably because the reservists usually spent a lot of time on roads within Canada, compounded with cheaper operation costs. Backed by local political support at Muncie willing to preserve jobs, their case was solid.

To convince Land Force Command, two engineers from DDGM made a design based on a small scale model of the LAV II chassis, removed the original troop compartment, added a large box on the rear half to increase internal capacity and replaced the former doors with a ramp similar similar to the one sported by the M113. This small scale model was shown to colonel Dallaire. But he was not interested in the proposal, and went on in his project on acquiring the M113A3, until DDGM decided to go above his head, playing its long embedded political contacts in 1988 and force the hand of the Canadian government. DDGM eventually won over the lower budget of the proposal Michael Wilson, the Minister of Finance, and several other members of Mobile Forces Command Headquarters based in Saint-Hubert, Quebec.

However, engineers and executives of DDGM continued to lobby Col. Dallaire to obtain the contract and decided to create a full-scale prototype for a presentation. DDGM brought it at the Canadian Forces Base Borden, unveiled under massive press coverage at the Armed Forces Day on June 5, 1988. Both Dallaire and Beatty were present. To gain time, working around the clock, engineers started with a battered tested LAV-25 used previously for airdroppings and modified the hull to fit the scale model.

In addition to making a new troop compartment, keeping the original suspension, drive-train and front half, they last task, most complicated, was to fit a working ramp, which they did under eight day. The turret ring was replaced with a large folding roof hatch, and the hull roof was assorted with a new raised commander cupola taken from existing stocks at the front left, behind the driver, a classic APC configuration. The bulgy rear part soon earned it the nickname "Bison", which was immediately marketed by DDGM. After being assembled, cleaned in and out, the prototype was painted anew, finished to show the internals, made ready to be shown.

The vehicle was driven up to CFB Borden and was presented during the parade on Armed Forces Day. The shown was considered a success, as DDGM staff invited Beatty to come on board and it seemingly won over his support. However Colonel Dallaire continued to support the M113A3 acquisition. DDGM then hired a top-end lobbyist to Ottawa, working out the existing arguments already presented to Beatty, notably on the cost-efficience and low maintenance, and speed. They also advanced the idea the Regular Force would made eventually the acquisition of new M113A3s. DDGM indeed seemingly new about the Regular Force likely reappropriation of the new vehicles for their own use.

In the end, it's the Army staff that went over the head of Colonel Dallaire and decided to purchase the Bison in July 1989. A firm order of 149 "Bison" armoured personnel carriers was passed, alongside 18 "Bison CP" command posts, and 16 "Wolf" 81 mm mortar carriers plus 16 "MRV Bison" (maintenance and recovery vehicles) making for a total of 199 vehicles. Production was setup already and finalized to start in early 1990, with the first rolling of the line in mid-1990 and procured.

Design

One of the key argument of DDGM was its production delay, extremely short. Indeed, there were little changes compared to the previous LAV-25 and thus the factory inly needed adjustments of its production line. The production Bison was baslically delivered as a stock LAV-25 but with the entire rear compartment missing, having only its front cabin. A new boxy, taller rear compartment built alongside was assembled, the roof was the same with a new commander cupola behind the driver. The last step was to install the rear ramp.The vehicle incorporates a rail mount system in the cargo and passenger compartment, making it mission-specific without any manufacturing, with kits provided to reserve units. The driver, like in the regular LAV-25, is seated in the front-left of the crew compartment, with the commander in a a slightly raised position, directly behind the driver. It had a specific access hatch and a ring-mounted machine gun. The engine was to the right of the crew compartment. The latter housed height infantry with her gear suspended or under them, with seating arrangements on rails allowed them to slide out through the large power operated ramp at the rear.

Powertrain

Engine and transmission are located on the right side of the hull. This was the same Detroit Diesel 6V53T diesel engine developing 275 hp as the LAV-25. The Bison is fully amphibious, only needs two minutes preparation, activating bilge pumps, sealing, erecting the trim vane, gearing out the propellers, etc. It is indeed given two directional waterjets at the rear. Tactically, the Bison has the same size and weight tolerances as the LAV-25 and can fit in the same transport aircraft.Protection

As for protection, is more heavily armored than the LAV-25, with a reinforced hull using the same angular shape (sloped armour) but attachment points to add various kits of spaced armor plates. The standard is full all around protection against shrapnel and heavy machine-gun fire, based on around 8-14 mm of extra-hardened steel RAH. Additional equipment also includes the classic NBC protection system. For active concealement, the Bison is procured two banks of smoke dischargers. The vehicle was not seen using BAR armor in Afghanistan but the fitting was an option considered for the upgrade as a field kit. The Bison is not mine-protected, the chassis stays flat, although measures were taken during the upgrade to improve its survivability.Protection

Armament of the base APC is limited to a 7.62 mm GMPG machine gun fitted on a ring over the commander's hatch. Smoke grenade dischargers can also fire antipersonal ammunition if needed. The roomy internal rear compartment allows to carry for the platoon a large array of weaponry, including ATGMs, mortars and MANPADS. The only "heavy duty" vehicle for armament is the Mortar variant called "Wolf".Modularity

The Bison's rail-mount system is the key of its adaptability: Without major modifications it could be configured rapidly as an armoured personnel carriers (used in that role until replaced by the LAV III) with two rows of seats facing outwards, and later inwards as the portholes were eliminated. The same compartment can be completely reshuffle to house the 81 mm mortar carriers. Same for the command post vehicle which is provided with its heavy electronic equipments, generarors and consoles, rearranged seating, plus a map table. The vehicle was also marketed as able to be converted as a field ambulance and mobile repair team (MRT) vehicle, armoured recovery vehicles to replace the Husky, both using similar configurations, but also the PC version was usable as an airspace coordination centre vehicle or electronic warfare vehicle. The MRT is also derived into an engineer vehicles, having hydraulic tools. last but not least, the Bison also existed in a NBC reconnaissance vehicle version.Original Variants

Basic Bison APC, production version

As seen above in the design description. 149 BuiltBison CP

18 command post variant: 18 with reworked internal rear compartment with an extensive com suite and satnav, satcom, plus telescopic antennae. Modernized in the 2000s with digital displays and datalink.Wolf MC

16 Mortar carrier version: The rear compartment received a new split roof hatch, internal racks for ammo, new floor to fix a dismountable mortar, etc.Bison MRV

16 maintenance/recovery vehicle dedicated to the field support of the Bison, organic to units as the Wolf and Bison CP.Service and upgrades

Combat-proven 1990-2021

Bison in Afghanistan, 2000s

The Bison was soon deployed The Bison took part in the Oka Crisis (1990), Gulf War (1990-1991), United Nations Operation in Somalia II (1993-1995), Yugoslav Wars (1991-2001) and War in Afghanistan (2001–2021). Canadian Bison armored personnel carriers were gradually replaced by the newer LAV III armored vehicles. Part of these were refurbished and converted into support variants: Ambulances, recovery vehicles, electronic warfare vehicles, of the list given above in "modularity". The new variants also had an upgraded engines as as said above, fittings for extra add-on and BAR armor, and many other improvements.

Bison in Ukraine ? With the replacement of both the LAV-III and LAV-6 (gradually the next years) it's clear that the pool of the refusbished vehicles could be used in Ukraine, provided the Canadian Army is willing to put them in shape and that they are still in storage. Recently, the Canadian Government instead sent to the Ukrainian military its most recent LAV ACSV "Super Bison" wheeled armored vehicles. The latter are an the final version of the Canadian LAV-6, with 360 currently on order.

Upgrade program 2002-2008

The Canadian Forces began upgrading the Bison between 2002 and 2008, which included improved engine power, new torsion bars for mobility, and for protection, the fittings for add-on armour (an BAR armour). For crew's living conditions, an air conditioning, and a VRS respirator system NBC (nuclear, biological and chemical) protection. More variant came out of these conversions as the vehicle was no longer used as APC, and existing vehicles were all made into specialized ones. This "second wave" of variants, was even more prolific than the first one, seeing the arrival of the following:-Field ambulance

-Bison MRT, Mobile repair team vehicle

-Bison ARV or armoured recovery vehicle

-Airspace coordination centre vehicle (ACV)

-Bison EW (electronic warfare vehicle).

-Bison EV (engineer vehicle with tailored hydraulic tools)

-Bison NBCR (NBC reconnaissance vehicle version).

These are currently in service, pending replacement for the more modern sub-variants of the Canadian LAV-III, sharing many caractsristics with the late versions of the Stryker.

Coyote specifications | |

| Dimensions | 6.39 oa x 2.50 x 2.69 m (21 x 8.2 x 8.8 ft) |

| Total weight, battle ready | 14.4 tons (28,800 ibs) |

| Crew | 4 (Driver, commander, gunner, operator) |

| Propulsion | Detroit Diesel 6V53T 275hp pwr 19 hp/t |

| Suspension | Dependent 8WD - Selectable 4WD drive |

| Speed (road) | 120 kph (75 mph) |

| Range | 660 km (410 miles) |

| Armament | M242 25 mm QF Autocannon (210 rds) 1 x 7.62 mm C6 coaxial LMG1 7.62 mm C6 roof LMG (660 rds) 2x6 cluster grenade launchers |

| Armor | Spaced, 8+8 or 12+8 mm front |

| Total production | 203 in 1996-99. |

Sources/Links about the Bison

army-guide.com

wikipedia.org bison coyote

warwheels.net

military-today.com

canada.ca

dewengineering.com (Bison upgrades)

armyrecognition.com

wikipedia.org/wiki/General_Motors_LAV

GM Canada (General_Motors_Diesel) branch

canadianmilitaryhistory.ca

Canada's Mechanized Infantry: The Evolution of a Combat Arm, 1920–2012

Gallery

Illustrations

Basic Bison APC in the late 1990s

Photos

Parked Canadian-Made stryker in Vancouver

Variants of the Bison II (2008)

Bison APC, ISAF, Iraq, 2000s

Same

Original Reserve Army Bison AP

Bison MRV

Bison Ambulance in Africa (peace keeping operation)

Bison Ambulance in exercize MAPLE RESOLVE 18 in Wainwright, Alberta on May 19, 2018 (FLICKR).