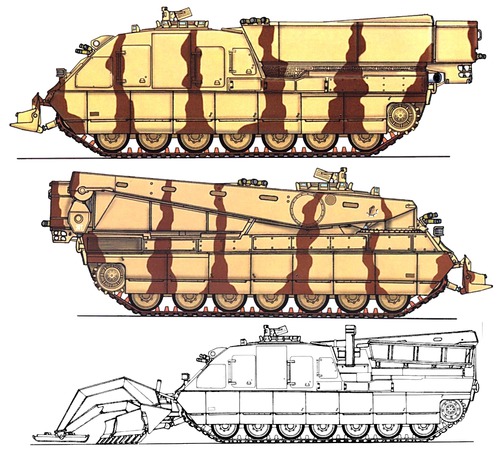

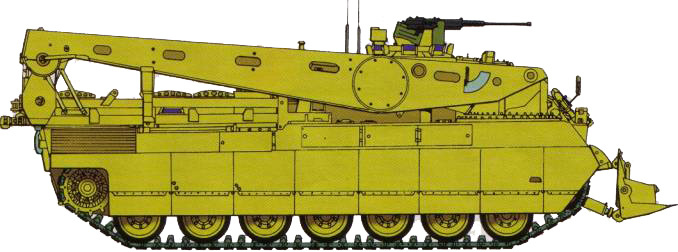

Leclerc DCL (1991) and EPG (1994)

Engineering and recovery Vehicles - France (1991-2000) - 66 built.

Engineering and recovery Vehicles - France (1991-2000) - 66 built.

The French modern engineering vehicles

The LECLERC DNG/DCL and the EPG are today's French Army Main Engineering Vehicles. Developed by GIAT industries back in 1994, the serie is now maintained by Nexter/NTDS. The first EPG, mine-sweeping variant, rolled in 2001, but the program was not followed, the contrary of the DNG (Leclerc Tank dedicated salvage vehicle) and the DCL with a serie taking place in the 2000s, now used by France and the UAE.The Leclerc DNG/DCL

The acronyms covered slightly different vehicles for the same purpose:DNC mean "Dépanneur Nouvelle Génération" (new gen recovery vehicle) or DCL for "Dépanneur du Char Leclerc" (Leclerc recovery vehicle) which is the final name.

The "Dépanneur de Char Leclerc", alternative designation, was designed designed to repair and evacuate the LECLERC, or up to 70 tons enabling NATO tanks recovery such as the Abrams, Leopard 2 or Challenger 2. Its development began in September 1991. The first working prototype was produced in 1993 and started a long campaing on field trials.

In 1994, it was renamed DNG ("Dépanneur de Nouvelle Génération") by the manufacturer but the name DCL was adopted in the French Army which is reflected in the prodction records. The initial order of 30 DCLs was reduced to 20 units in early 2002 as production was already running from 1998.

A DCL at Bastille Day 2006

Design of the DCL

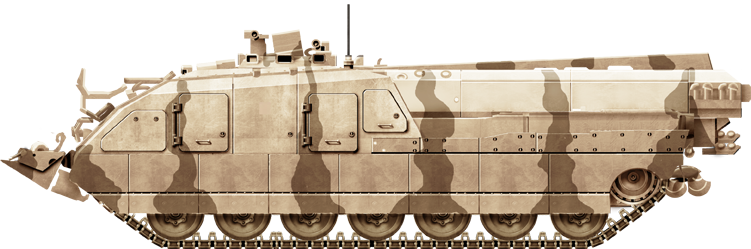

The DCL is a large vehicle. With nan extra axle, seven roadwheels instead of six, it is 9.15m long, 3.38m wide and 2.60m tall for a 60 tons mass in working order. The chassis is the same, with a large casemate taulor-built above to fully protected the crew of three (commander, driver, servant/mechanic) with a folding seat which can accommodate a fourth crew member.Its powerplant is the same as the regular Leclerc Tank, the MTU 883 V12 turbocharged diesel whihc is rated for 1,500 HP, procuring a power-to-weight ratio of 25.5 hp/lt. It is coupled with a German RENK HSWL 295 TM transmission, automatic 5 forward gears, 3 reverse gears geabox. Its top speed it almost as good as the original Leclerc, the world's fastest MBT when unvailed in 1991. The DCL top speed on road and flat is 72 km/h, and Off-road up to 55 km/h. In reverse it is still capable of 38 km/h.

The Fuel capacity comprised two main tanks woth 1,500 liters giving a 500 km range in normal conditions. The suspension system is also the same as the regular Leclerc: Oleopneumatic, but with a system blocking the cylinders of the rear suspension during crane operation to avoid damage. The tracks are also the same, with common drive sprocket and idler as the original Leclerc. There is a tensioning system adjustable from the pilot station.

Armament is limited to the roof machine gun around the tank commander, a standard Browning M2HB cal. 50 or 12.7 mm, manually controlled by commander, which is exposed to enemy fire. An RWS was proposed by Nexter in 2018 for an upgrade but not adopted. 300 rounds of Ammunition are carried, with three magazines, one mounted already.

The protection comprises the original chassis and a new casemate which is compatible STANAG 4569, for logistics vehicle, and assumed to be immune against 14.5 mm Russian type heavy machine guns, AP rounds, and against artillery shrapnels. The nose is further protected by the shovel, and the crew inside by various external apparatus and tool boxes as the main crane. Active protection comprises the GALIX protection system as for the Leclerc MBT, 20 launcher tubes with smoke bombs and close defense grenades. The Hydraulic compartment is isolated from the crew. The interior is protected with a collective NBC, with slight overpressure and air conditioning system. There are Halon-type automatic fire detection and extinguishing system both in the crew compartment, power unit, and hydraulic compartments.

Observation: The commander benefits from a cupola offering a 360° panoramic view with nine daytime periscopes and an Episcope with intensification of light for the pilot, enabling night driving. The assistant has no observation device.

The vehicle is fitted with a Radio with frequency evasion radio set and an Intercom at all three crew stations. For navigation, the DCL uses Hybrid navigation system or GPS.

The "Leclerc Char Dépanneur" (Giat and later Nexter called it the EPG) is called DCL in the French Army. It is as heavy armored as the main battle tank it is suppose to recover or repair on the frontline and is tailored with a new chassis derived from the LECLERC 70 tons main battle tank.

Main Features

Leclerc DNG profile

The Leclerc DCL has a crew of three:

-The tank commander, present in his cupola forward, and conducting operations on site. He also uses the radio and defensive armament.

-The driver, in the same place as for the original tank and performing all vehicle's mobility functions.

-The assistant mechanic, which is responsible for maintenance/repair and salvage with the driver and has his own dashboard and compartment.

-A main winch with 35t capacity, 180 m long () steel cable, usable in single or double haul.

-An auxiliary winch, capacitt 1.3t, 230 meters long.

-The Excavator shovel, 3.40m wide, controlled from the cockpit. Used for landscaping, anchoring, trimming the tank during crane operations.

-The main hydraulic Crane, of 30 tons capacity, operated from inside and outside.

-Tooling contained in the rear box module (MCA), which can be deposed by the crane.

-The auxiliary generator (APU) supplying electrical power when the vehicle' engine is cold. It also powers all the electronic systems aboard and is assisted by pneumatic systems.

-20 smoke launchers (DREB) similar to the Leclerc MBT's GALIX system.

-A 12.7 mm (0.5 in) heavy machine gun for close defence, mounted on a rail around the commander's cupola.

The Leclerc DCL is powered by the same engine less the helicopter-type turbine APU. It is still capable of negociating a 50% climb and 40% side slope and is amhibious to some degree: It can ford without preparation 1.5 m of water. Details of the kit offered for fording larger rivers is not known, probably derived from the Leclerc MBT own system. As for tactical mobility, it is carried by train but only the heaviest cargo planes sch as the American Galaxy C-5 or Ukrainian Antonov are capable of lifting it.

The Leclerc EPG

Development and Design

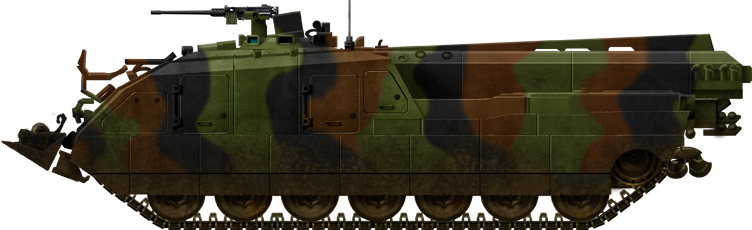

The first prototype was completed in 2001.This EPG was a first Main Engineering Fighting Vehicle developed by GIAT from 1994 on the basis of the DNG, was to be the successor to the EPG based on the AMX-30 chassis. It had an articulated arm which could receive an excavator bucket but also a grapple, shovel and auger as well as a large winch and hoist with a lifting hook.

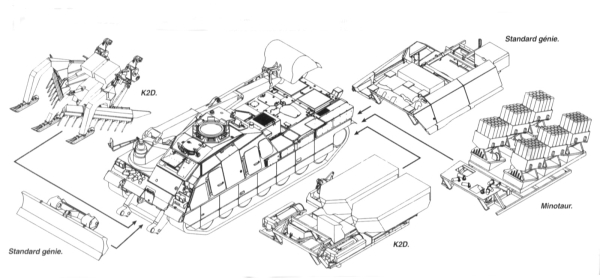

The EPG is based on the chassis planned for the DNG by exploiting its modular capacities to make it a general-purpose combat engineering vehicle (CEV). A standard version sees the installation of a digging arm allowing a grapple, shovel, auger, hoist and hook to be fitted to the crane. The rear shelf comprises a standard engineering platform, with a full destruction kit. The front anchor shovel is there replaced with a dozer shovel. The DNG anchor blade is replaced by a dozer blade. The rear utilitarian flatbed could receive an assortment of tools depending of the mission at hand.

Deminining Kit

The K2D module is a Demining Kit which could be fitted on the LECLERC EPG but also made adaptable to all vehicles of the 50-60 ton class. The K2D comprised four main parts all fitted to the chassis:- The large-width PEARSON plow weighing 3.4 tons that goes down to 30 centimeters deep. Equipped with 21 teeth, it has a width of 4.25 meters.

- The DEMETER electromagnetic duplicator. This system prematurely detonates magnetic mines near the vehicle. It is placed either on the front of the frame or directly on the Pearson plow.

- Propelled detonating cords or Fuel air Explosive rocket. This pyrotechnic device is carried in rear lockers. The cords are propelled by rockets and are then ignited. They can thus clear corridors 110 meters long and 4 meters wide.

- Pathfinder Beacons. Two beacon containers are attached to the rear of the tank. They propel reusable beacons into the ground so as to delimit the cleared corridor.

Other Variants

The Leclerc chassis has been tested also for a heavy APC and an IFV (separated future articles). The unarmed chassis was also used for three other main variants:MINOTAUR

The Minotaur module includes 6 launchers placed on the rear platform. It allows the mining (anti-tank mines) of an area of 2400 meters by 250 meters in less than 5 minutes.LECLERC PTG

The LECLERC PTG (for "Poseur de Travure du Génie") "Engineering Crossing Installer" is a bridge carrier project (BGL) developed from 1996 with two spans planned: A double span of 26 m or two single spans of 14 m. No prototype was built and it remained at model stage.LECLERC MARS (2003)

To make up for the reduction in orders for the DCL (20 instead of 30), Nexter approached the DGA (French procurement agency) with another concept vehicle called MARS (Moyen Adapté de Remorquage et de Soutien) or loosely translated as "Appropriate Means of Towing and Support". It was studied at the end of 2001 in the technical section, 12th BSMAT in Gien. The preliminary draft was presented on November 1, 2001. Eventually it was given the greenlight for the construction of a prototype made on the basis of the LECLERC T3.

The big difference with previous vehicles is that the chassis is exactly the same and turret unchanged. The major difference is that the gun components are removed, freeing the interior and making the turret lighter by 5 tons. The location of the 120mm gun is obscured, an additional storage basket at the neck of the turret comparable to the Leclerc UAE is installed. The Mars comprises tow bars, and working light recycled from an AMX 30D.

Following trials at Mourmelon in February 2002 and a maneuver in Ukraine, it was decided to equip each Leclerc regiment with an example of Mars. Some changes were made, such as the simplification of toolboxes and removal of the porthole. In Ukraine, the prototype, formerly named "Phenix I" was renamed "NICOLAEV".

The Leclerc DCL in service

The DNG/DCL recovery tank uses recovery elements from the German Büffel recovery tank, itself based on the Leopard 2 chassis. The name DCL also applied to the first version and DNG to the second version, modernized, in the French army. Its main purpose has been the recovery of 50 tons tanks and armored vehicles to be evacuated out of the combat zone, repair them in the field f the damage was not too great, maintain them for exemple by changng the powerplant unit, thanks to its crane and serve as a "general purpose" engineering vehicle thanks to his shovel, or minesweeping vehicle with the K2D kit.So far, two DNGs and 18 DCLs are in service with the French army, with one following the 13 Leclercs deployed to South Lebanon for the peacekeeping mission with UNIFIL in the late 2000s. The United Arab Emirates purchased 46 DNGs which are now deployed in Yemen to assist their tropicalized Leclerc EAU with a park of 388 Leclercs total.

With the ongoing conflict in Ukraine, it is possible that if the Main Battle Tank is deployed in turn, it will be probably accompanied by several DCLs.

Leclerc DCL specifications | |

| Dimensions (l-w-h): | 7.6 x 2.98 x 3 m (24'9'' x 9'77'' x 9'84'') |

| Total weight, battle ready: | 23.3-25.6 Tons VCI/VPC (50,000 ibs) |

| Crew : | 3+9 (Driver, Commander, Gunner, 9 infantry) |

| Propulsion: | Renault Diesel 550 hp (410 kW) 24-22 hp/t |

| Suspensions: | 8x8 Coil springs/shock absorbers |

| Top Speed | 100 kph (62 mph) |

| Range (road) | 750 km (470 mi) |

| Armament | GIAT M811 25 mm, coax. 7.62 mm LMG |

| Armour | 14.5 mm (0.57 in), NATO STANAG Level 2 |

| Total Production | 630 as of 2017 |

| For information about abbreviations check the Lexical Index | |

Gallery

Leclerc DCL in basic green livery

Leclerc DCL of the United Arab Emirates Army, deployed in Yemen

Leclerc EPG

Links, Resources & Further Reading

EPG on chars-francais.netDCL on chars-francais.net

On the Leclerc Mars - chars-francais.net

On fdra-ejercito2

On defense.gouv.fr

On military-today.com

On armedconflicts.com

On the leclerc mars

weaponsystems.net

Leclerc On wiki FR

defense.gouv.fr

The DNG on fr Wiki

army-guide.com

On leclerc.fr

Video

Modern Tanks

Modern MBTs posters

Denel Bagder (2018)

Type 16 MCV (2016)

Gepard 1A2 last rounds 2011

SANDF

Russian AFVs

Main Battle Tanks