YP-408: The Dutch wheeled APC

Barely known outside the Netherlands and exported to a few countries, the YP-408 was designed in the 1950s and therefore is one of the earliest examples of the kind, outside USSR's BTR family. It was contemporary to the French EBR-VTT and the first Swiss Mowag prototypes. DAF produced 7,50 vehicles (not included prototypes and some variants) in the 8×6 configuration according to DAF typical H-drive. In addition to the Dutch army -they were reformed in 1987 and replaced by more modern German/Dutch vehicles such as the Fennek- the Portuguese and Suriname army also used some until the 2000s.Development of the YP-408

DAF, the national truck manufacturer, has already produced the DAF M39 Pantservagen before WW2. When the Dutch army started to seek for a national Armored Personal Carrier (APC), development started in the late 1950s of new vehicle. It was further developed as the YP-408. The YP-408 answered a request for a vehicle able to move the infantry quickly and safely on the battlefield. It has to be if possible entirely designed and manufactured in the Netherlands. The final prototype was tested by the Dutch Army in 1959. Its design was based on the previous DAF YA-328. The famous 'Dikke Daf' three-tonne truck allowed many parts to be reused, and the final vehicle therefore was easy to integrate into the existing military supply and maintenance systems of the Dutch Army. The designation of the vehicle was derived from the letter Y for "military vehicle", P for "armored car", 4 for the load capacity in tons, 0 for the series, and 8 for the number of wheels.

Demonstration of the prototype in 1959.

First public reveal

Much has been written about this vehicle, it always had been stated that it was developed and an armored infantry carrier. But it is at odds with the truth. The reason for its existence subsequent development into an armored infantry vehicle was a complicated process. On June 16, 1959, a vehicle day was organized by the Royal Netherlands Army, at Oirschot (now De Ruyter van Steveninck Barracks). In collaboration with DAF, the largest supplier of the Dutch armt so far, there was an overview of different types of tactical wheeled vehicles in use by the Royal Netherlands Army (RNA). This was not comprehensive, but post-war vehicles were the most common and arranged in a large circle. Among them, an armored car in particular drew attention: It was the DAF YP 408, shown for the first time. That day not les than three were on diplay at Oirschotse heide.In July 1959, the official organ of the RNA, the "Army Courier", paid attention to this even and noted the YP 408. According to the article, the vehicle had been experimented to carry a detachment of infantry, specifically designed by the Detachment Vehicle Testing (DBV). It was a branch of of the Technical Service Inspectorate, under command of Captain J.J. Pop. The latter ordered prototypes to by DAF. The aim of the new vehicle was to carry a tirailleur detachment or mortar crew quickly in the battlefield. Performance was paramount, but it seems the vehicle did not met the requirements for an armored personnal vehicle carrying infantry. Indeed, only six of the eight wheels were driven, a disadvantage as the vehicle could get stuck when negotiating tight obstacles. The Army Courier article was a bit more positive, stating that the six-wheel configuration however incorporated both idle support wheels as steered, and sprung wheels at the front like a half-track. But this four-wheel steering make it easy to overcome rough terrain anyway. The article also underlined the fact it was 100% of Dutch design.

The instruction model

A secret vehicle Designed for the Royalty

Fact is, that the YP 408 shown on June 16, 1959 belonged to the first prototype serie of three vehicles ordered for tests. They had license plates, and this was remarkable as vehicles ttested for the KL were all given number plate, sometimes not for long, in the KZ-99-00-KZ-99-99 series, like KZ-99-77 and KZ-99-78 for the YP 104, and until the development of the YA 4440. This was a registration number which did not indicated development or testing but normal road use. The interior design indicated also different purposes, as by then it was too generously furnished and polished for a prototype, notably for the canopy with pads and lights.The YP 408 was indeed developed not for poor infantry but rather for the Royal Netherlands Marechaussee! To be precide, the G-squadron established in the mid-1950s, commanded by the National Territorial Commander. The Royal Netherlands Marechaussee was tasked for the security of the Royal House. This included evacuation of members of the Royal House in case of an alarm of a Soviet attack. The unit was equipped by four White M3A1 helf-track specially adapted for this purpose. At the end of 1956, a meeting took place at the initiative of the Sous-Chef I, General Staff. It was decided to replace these halftracks, presumably as they did not met the requirements. For this development, the Directorate Materieel Landmacht (DML) was bypassed, ans a confidential letter was adressed directly to DAF, asking to inverstigate possibilities of captain Pop's requirements.

On behalf of the Chief of the General Staff, Pop contacted Dr. H.J. van Doorne, at least to know it it was opportune to develop an armored car using components from the DAF YA 328, without mentioning its purpose. Dr. van Doorne answered yes, and was reocntacted by the Inspector of the Technical Service (the superior of Captain Pop) on November 27, 1956. At that point it was decided that three armored cars were needed. And also they needed to be ready within a year. Development work was conducted by DAF already in early 1956 and quickly established the YA 328 chassis was too weak to support an armored body. But most components of the latter could be incorporated in the design to gain time and spare cost. Thefeore the small 4x4 YA 328 became a starting point, despite it looked like a copy of the British Daimler Scout car. Requirments included a high road speed and off-road capabilities. The armoe thickness was not decided yet, athough proof against small arms fire, and the vehicle was supposedly unarmed.

DAF YA-328, the base for the design

Design development

It was also studied if existing army vehicles could be converted into armored vehicles. Later the option was dropped due to the same considerations as fo the YA-328. The Inspector of the Technical Department suggested starting a wooden mock-up model made in hardboard to be checked and see if future changes could easily be made. By that time DAF did not ommunicated yet on the cost of three vehicles but the acquisition process was quick and efficient nevertheless, as by December 1, 1956, the CGS informed the Director of Army Materiel that it required the purchase of three 'DAF YA 328 armored cars' for G-squadron KMar. The wooden mockup was also approved and all was setup for a delivery before the end of 1957 and cost was not an issue.The Head of Vehicle Division sent later a letter to the Director of DML on December 8, 1956 which alledged the DML had been bypassed. The head of department complained about the intended purchase, as never discussed in the Motor Equipment Working Group. He later contacted Dr. van Doorne, the latter revealing the confidential exchanges between Captain Pop and himself. In the end, it was settled, and an order for three prototypes to DAF formally written down on 19 July 1957. The contract specified Van Doorne's Automobielfabriek NV DAF to supply these three armored personnel vehicles called YP 408 (internal factory designation) using components from the YA 328 truck to lower costs, plus a wooden mockup to be delivered first.

It was also specified the armor plating would be supplied by the State to lower the burden on the company, and some specific subsystems like the periscopes. The armor plates in fact were easy to find: They came from the soon-to-be broken up half-tracks to be replaced. Still at that point no unit price was fixed although the state suggested fl. 135,000 (394,000 Euros 2016). It was agreed that final technical requirements would be determined during production, in close coordination between DAF and DML. For Dutch army standards, it was a very unusual contract, showing the high priority and secret nature of it. However the company soon had issues with the design and the deadline of the end of 1957 was not met.

The first vehicle was delivered to DBV on January 30, 1958 and the others in June 1958. In February 1958 already, the first prototype was tested at the factory, condronted with the DBV 54 points noted. One of these request was the fitting of an ashtray... Indeed in theory the new vehicle was a successor to the 'gold car' of the Dutch Bank used by the royal couple and children, carrying them from The Hague to IJmuiden in May 1940 before they departed to the UK. In all documentations of the time, these APCs were referred as 'Marechaussee cars'. This was a rather long vehicle, 6.10 meters overall, but 2.40 meters wide and 1.80 meters high in order to be carried by rail and do not exceed the smaller bridges in the country, but also dictated by a chassis derived from the YA-328.

Final Design of the YP-408

Of course, the luxurious interior was amended for troop transport afterwards. One of the first three vehicles was modified by using summary benches fitted on either sides and doubling as storage bins. The downward moving part of the rear door was also folded up and down, through wires coming out of the benches sides. These two steel wires were attached to the outside of the left and right flaps with profiles. The modified benches later no longer extended to the floor, ensuring suspension and some form of protection against undervbelly explosions, although this was far from being sufficient. The APC never was designed to survive a mine blast. These benches were placed high-up, to allow the trooped to be seated and be seen at the rear of the vehicles through large openings.

Two vehicles in training during the winter

Powerplant

The powerplant was made by DAF, a six-cylinder, 4-stroke, liquid-cooled DS-575 diesel engine. It had overhead valves and a turbocharger ensuring the pressure increase of the intake air. This precompression allowed better combustion and greater power, powered by the exhaust gases as custmomary in that case. Power transfer case called for a 5-speed forward and reverse gearbox, served via a single dry plate clutch. 2 to 4th gears were synchronized and the Fifth was an overdrive.To be more precise, the engine had a 100.62 mm bore, 120.65 mm stroke with a 5753 cc volume, a compression ratio of 16:1. The combustion called for a direct injection toroidal swirl chamber in the piston head. Gross power (SAE) was 165 hp at 2400 rpm and torque 52 mkg/1600 rpm. Max. adjusted speed ranged for 2600 rpm (empty) to 2400 rpm loaded, and for idle speed it was circa 500 rpm. Valve clearance of the inlet and outlet was 0.5 mm maximum oil pressure with warm engine was 3.5 - 4.2 kg/cm² down at 0.35 - 0.50 kg / cm².

Performance:

60 km/h flat in cruise, 4 km/h minimum, and it was able to reach a gradeability between 21% and 50% between high to low grade. Fuel consumption was 3.4 km/liter on the road, normal use, and up to 15 to 20 l/h offroad. Range normally loaded was 500 km. (From the Technical Manual of April 1964). The chassis made by DAF was based on a truck with outstanding off-road capabilities. It used eight wheels, of which six were powered. So this was quite a unique 6x8 configuration.Power Transmission

The front axles had independent suspension, and could be steered together. The swingarm of each one was equipped with a bogie set, with a self-supporting hull body above. The powerplant output as distributed by a reduction gearbox, which had central differential and distribution boxes. The reduction gearbox was mounted behind the gearbox, connected by a short intermediate shaft. The reduction box had gears for high and low transmissions, plus a central differential. The two distribution boxes connected the reduction box via shaft sleeves and the whole assembly was encased in rubber to avoid vibrations, at three points of the hull. The reduction gearbox in practice allowed the driver to further reduce any gear ratio and find the optimal traction for all terrains encountered and any condition. The differential was housed in a cast structure foward of the gearbox. Its pinion gear was integral with the lower axle and the crown gear mounted in the right axle tube. The two distribution boxes used a bevel gear transmission, as the axle tubes had inner short half-shafts, for the drive, front and rear wheels only, as the second front axle was idle. The front-wheel drive was activated by a lever and operated the switch boxes, forward of the distribution boxes.The main drive from the engine was transferred from the differential to the distribution boxes, through the axles, via intermediate shafts at the front and rear. "worm gear" were used and each wheel was driven by a thru axle inserted into the hub of the worm wheel. The front-wheel drive used worm boxes mounted on wishbones on steering knuckles. These thru axle had both long and a short parts connected by a Bendix CV joint. They ran on conical roller bearings on the stub axle. The rear wheel drive when engaged, had worm boxes suspended by balancer holders on tailored beams. These also contained the anchor plates, and the thru axles were self-supporting and topped by a flange. The wheel hub had conical bearings too.

DAF YP-408 prototype in field trials, 1959

Suspension:

The wheel suspension were independent of any move of the axles and wheels: Worm boxes always stayed in their horizontal position. The front wheel drive suspension used a pair of wishbone arms for each wheel. These were welded to transverse sleeves mounted on bronze bearing bushes outside. They were located in their own bearing support and inside a clamping box. In each tube the main torsion bar was located, grooved on both sides, with greater outside diameter, fit the corresponding ones in the transverse sleeve, smallest fitting thoese in the clamping box. The second front axle were independently suspended by transverse wheel arms, two longitudinal torsion bars in tandem (one behind the other). Outside the wheel arm was connected via a long sliding sleeve with an inner and outer part. The inner sleeve when compressed slided up in the outer sleeve, up to the upper cup springs. In emergency, the two wheels of the second front axle could be lifted and suspended from the hull independantly with appropriate chains and high enogh to be used as spare wheels.The rear wheel suspension were both in tandem on an single axle connected to the hull by longitudinal leaf springs. Vertical carrier plates were welded on both ends of the axle beam. Balancing shafts were mounted in beams with bronze bushings with the wheels and worm boxes mounted on hollow shafts in balancer holders. The deflection was determined by boundary wires, and suspension counted on two semi-elliptical leaf springs front of the axle.

Road Wheels:

Each YP 408 was given a set of 8 roadwheels. In all six could be drive, the front wheels and the rear four ones. The second axle wheelset could be steered like the first front axle and each wheel had an external tire, and Inner tube and a two-piece wheel rim with 16 rim nuts, a rim tape and 8 wheel nuts. The tires measured 7.5 '' x 20 ''. The wheel rim was made in aluminum alloy; with a 275 +/- 0.1 mm diameter, and hub bore diameter of 221 mm. The rim nuts connected together the two rim parts while the was stuck between. The wheel nuts fixed the complete wheel to the wheel hub. These were painted RED as customary for these vehicles in peacetime. There was no proper centralized tire inflation system. Normal pressure of 44 ibs was maintained for hard surfaces, but the manual gave instruction to deflate the tires down to half this, at 22 lbs or even to 15 Iba the get the maximal traction on sand, snow and mud.Armament & Protection

To the exception of the antitank PWAT and the mortar PWGWT, all YP-408s were equipped with a ring-mounted heavy Browning M2 .50 (12.7 mm) machine gun. The heavy MG was given enough elevation to be used against air targets. For active protection, these vehicles also had two series of three launchers smoke mortars each, electrically fire and mounted on the forward hull's hood sides, facing forward. These were protected by framing tubes against vegetation and obstacles, as were the road lights and blackout lights. They could be ignited electrically by pressing a fire button located on the firing switch box, one for controlling three of them. So pressing both fire buttons launched all six, and for safety they were shielded to prevent error manipulation. These plastic launch barrels were attached to the holders with bayonet locks for easy replacement.

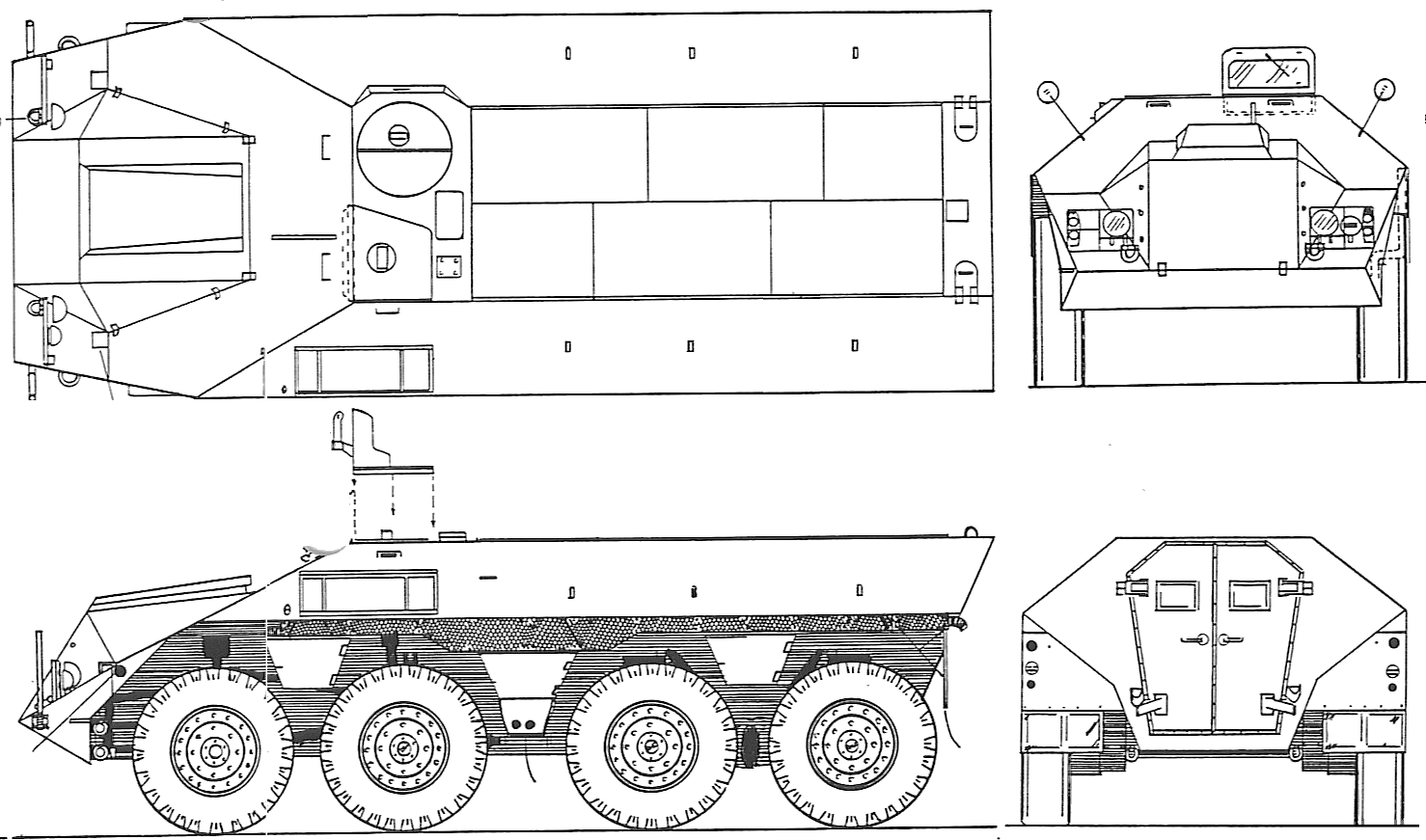

DAF YP-408 blueprint, base APC without the ring mount

Of course, the main armament of the vehicle was carried by the troops it transported. In that case, ten infantry in total, seated on banks face to face and with not much legroom. The long engine and transmission pushed the driver and commander, seated side by side on either side of the transmission tunnel almost at half the lenght of the vehicle. The troop compartment was just behind, for about 2/5 of the total lenght of the vehicle. Theerefore, the platoon commander coukld discusse directly with the commander and driver. As a platoon, they carried their individual assault rifles, a sniper rifle depending on the mission, a small portable mortar, RPG, or light MANPADS. The remaining two members of the crew then could man the light and heavy MGs for close support after the troops disembarked. The vehicle was not NBC protected as there were hatched over the soldier's heads whe thay can stand to fire on the move. There was no room for pistol ports and their position was awkward to use them anyway. The protection was sufficient to protect from shrapnells and small arms fire, 7 mm or RHA all around and 12 mm at the front glacis slope. The gunner was partly protected by foldable armoured panels making on eithe side but no frontal shield. This was the 1960s conception of the time, today oy would have received a RWS instead. Wikipedia states the vehicle could also equipped with a single 7.62 mm MG without precisoon, so it's fair to assume it was alternative to the main ring HMG.

Visibility

In total for all around visibility, the vehicle was given five episcopes and a periscope: One for the driver and gunner rotatable 360°, one located in the driver's hatch and in the PWI-PC and the PWI-CO versions an additional observation epicope was fitted for the commander. There was one persicope aft of the vehicle, and a set of four fixed episcopes on either sides of the driver's compartment. The rotatable episcopes were protected by an armoured hood. The main periscope driver's hatch episcope could be replaced by an infrared model, while another infrared viewfinder could be coasially fitted on the .50. The was also a 22 cm diameter infrared glass mounted on the the spotlight. Two headlights had this as a standard.The main telescope AI-65 had a field of view of 15° but can angled to 5° downwards, 10° upwards if needed. it was mounted on a rotatable ring for a full 360 ° with some suspension to be able to see when driving or stationary. There was also a telescope to identify distant targets and group constellations for navigation in normal weather conditions at 500 m and up to 1500 m. All on-board weaponry, ATGMs and mortar could be directed from the telescope. It was given indeed a ring with a clock division above the eyepiece, to be read to determine quickly any military azymuth. The lens used a 1/1000 magnification.

Communication

The vehicles used by default the Philips RT-3600 radio, which was modern in the 1970s. It was tailored for the army and quite modular, it could be adapted to any requirements of organic units within a formation. These radios were therefore used from the battalion commander level down to infantry group level. For example a full battalion comprised a Battalion Commander vehicle, an Operations section with the captain's head connections, and Information section; 5 company commanders, a fire control center for the mortars, a platoon commander of the anti-tank platoon, an added field artillery battery, an EskC (added tank squadron) and its platoon commander with a special assignment. All needed to communucate, from a 8 to 15, to a 30 km range.Production and service

The chassis numbers was stamped on the right side, above the front rear axle. The register showed production records: The order 470 for 250 vehicles (contract A 21.8340.11, May 12, 1961), order 3500 for 349 vehicles (contract number A 21.4326.12, December 10, 1964) and order 4200 for 151 vehicles (contract number A 21.5432.11, December 13, 1965), so 750in all.Production of the YP-408

In all, DAF would built some 750 vehicles, including 429 PWIs to carry infantry, of which 29 were converted to PWRDR and 55 to PWAT standards, but also some 179 PWCOs, 28 PWGWTs, 86 PWMRs and 28 PWVs (see the variants). In 1960, DAF built a 4x4 light vehicle, four-wheel-drive, of a reconnaissance car: This became the DAF YP-104. It was propelled by a Hercules JXLD, 6 cylinder gasoline engine which developed 131 hp at 3.200 rpm. However only three were built an tested in 1960-62 but not adopted by the Dutch Army. DAF also built the tracked APC/IFV YPR-765 under license in the 1980s. The latter replaced already part of the fleet of YPR-408s. DAF also developed a partnership with German Krauss-Maffei Wegmann and co-manufactured in the Netherland the Fennek, used as a reconnaissance APC. YP-408 used by the Polícia Aérea (Portuguese AF military police), in the air base security role, from 1993 until the early 2000s. 28 vehicles were employed that way, leased by the Dutch. Credits http://gaf.zeelandnet.nl

YP-408 used by the Polícia Aérea (Portuguese AF military police), in the air base security role, from 1993 until the early 2000s. 28 vehicles were employed that way, leased by the Dutch. Credits http://gaf.zeelandnet.nl

Variants

YP-408 PWI-S and GR (Groep)

Pantserwiel Infanterie Standaard: Basic version, two-man crew and ten infantry, Browning HB 12.7mm HMG. 429 produced 84 converted later (PWAT/PWRDR). The PIS(G) was modified to carry an armoured infantry section. This was the standard armored infantry carrier vehicle, comprising a driver, gunner, vehicle commander, 9 infantrymen. The Dutch term "PWI" was the acronym for "Pantser Wiel Infanterie". Roughly the equivalment to "APC". Three of such vehicles were supplemented with a PC platoon commander vehicle, with together formed a vehicle platoon. Three platoons (12 vehicles) formed a company, plus thsed carrying the company staff (commander and deputy Cdr) each with their own command version, to 14 in total.YP-408 PWI-S(PC)

Pantserwiel Infanterie Standaard (Pelotonscommando): Platoon commander's variant, RT 3600 Radio and two antennae. The PC (Platoon Commander) version is technically the same as the standard APC, one being assembled after three GRs, so 107 in total. Their equipment comprised the Carl Gustav TLV or later Dragon group. For this purpose, fastening clips were fitted inside to hold the charges, two antennas and extensive radio set plus an upgraded periscope and observation scope. The vehicle carried a platoon commander and six men, which made the Carl Gustav or M47 ATGM Dragon group. The latter comprised a launch unit M222C2 an IR SU-36P sight with a 1000m magnification, a launch speed of 75m/sec and up to 100m/sec in flight, or 11.1 sec autonomy carrying a shaped-charge warhead capable of getting through 80cm RHA.YP-408 PWCO

Pantserwiel Commando: Command vehicle, additional radios, desk with special lighting, six men (179 additional built) The CO (company commander) version had a more extensive radio suite on board, a map table with special lighting also, and carried a tent kit to enlarged the available space around. It was stationary for long, and its tent could be attached to the rear. It also had extra batteries built in to power the extra radions. The crew comprised in addition to the usul gunner and driver, three assistant soldiers and the CC. For xtra comfort it hd an additional built-in diesel-fired "Eberspächer" heater. The latter was later adopted by the TOW (AT) versions. These vehicles sported an the outlet extension hose, on the left flank and extra antenna pockets.YP-408 PWGWT

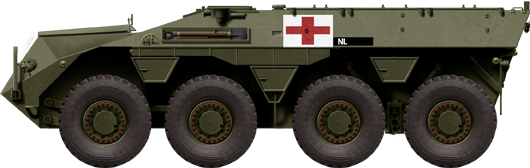

Pantserwiel Gewondentransport: Ambutank, 3-men crew (with signaller and medic) 2 stretchers, four seated wounded (28 built) The YP PW-GWT could accommodate two patients lying down and four seated and carried two medics in addition to the driver. To comply woth international regulation, it was omitted the smoke grenade launchers and HMG. Two more extra stretchers were fitted on the left inner wall and exhaust shortened like on the cargo version.YP-408 PWV

Pantserwiel Vracht: Supply vehicle with a 1,500 kg payload (28 built) Ths standard cargo version had only one driver and one gunner as a crew, which also helped unloading and loading operation. In the rear, the whole troop compartment was modified to mount a sturdy loading floor made of 5 removable plates, capable of supporting a payload up to 1500 kg. There was safety fence and door separated the cargo bay from the crew in front in case the vehicle was in a steep slope if the cargo was not fastened well. Insde door handles were also protected by fences and sheet metal. The vehicle was externally catacterized by its shortened exhaust. The idea was to reduce sparks reaching the cargo area, especially if ammunition was carried. Close to the ambulance version, stretchers could also be attached on the inner left wall. There was no radio or antenna onboard and no levers to open or close roof shutters. The HMG ring mount was simplified, as there was no elevation gear. It's possible this version was equipped with a lighter MG.YP-408 PWMT

Pantserwiel Mortier: Mortar variant, towing a 120mm mortar, five-man mortar detachment, 50 shells (86 built) Contrary to vehicles carryong their mortar inside, this variant was designed as a towing hok and gear, for the 120 mm Brandt-Raye mortar. The rear compartment was transformed in a storage space, roomy enough for fifty 120 mm mortar shells, and still had seating for the five mortar crew and officer. To maximize communication, the mortar commander had his seat directly behind the driver, close to the radio. The latter could be tailored and installed as needed depending on the level. To open the rear doors with the towing hook, they have been adapted. The heavy Brandt-Raye mortar was settled on an axle for easy mobility, and had a max range of 8000 m, down to 1000 m, with a rate of fire of 18 shots/minute, either high-explosive, smoke (phosphorus) and light shells, and can be deployed within 8 minutes. The mortar had a rifled barrel for more accuracy and its ammunition had pre-grooved sliding belts. In total, a brigade was allocated 144 rounds per mortar, carried by the PWV, and in all armored infantry battalions there were 3 platoons of 3 such vehicles.YP-408 PWAT

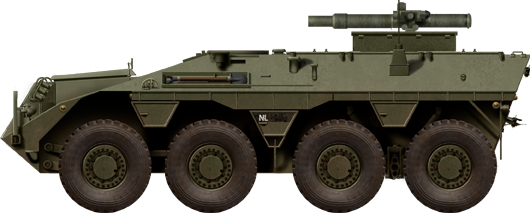

Pantserwiel Antitank: Anti-tank vehicle, TOW missile at the rear. 4-man crew, 55 converted from the basic APC. The standard Armor Wheel Anti Tank (PWAT) was given the standard NATO TOW (Tube-launched, Optically tracked, Wire-guided missile) ATGM. The top of the vehicle was modified to manage two identical, large shutters. An hydraulic gear was fitted in the crew room with a double-acting hydraulic cylinder and clamping device, same as on the ground mount. The ensemble rested on a bolted-on platform over the floor. It was used to elevate the TOW launcher. Another gear was used for traverse and some elevation. Racks were placed on the inner walls to hold additional TOW missiles. There was enough space for 8 such missiles. No need for a presentation of the BGM 71A, which was the best NATO ATGM for a solid 50 years, giving with three platoons, a solid anti-tank capability additional to the shorter-range Dragon crews of the PWI-S(PC).YP-408 PWRDR

Pantserwiel Radar: Carried a Marconi ZB-298 Battlefield Surveillance Radar on the roof, behind the MG mounting. It could also be placed on a tripod outside of the vehicle. 4-man crew, 28 converted from base APC (circa 29 built). This radar variant was included in each reconnaissance platoon, consisting of 4 Land Rovers armed with MGs, two mechanics and radios, and three YP408 RDR. Only two were manned in peacetime to save budget. The radar crew consisted of a Sergeant, two radar operators and the driver. The vehicle was mostly uncharged, still having its MG mount (empty on photos), while the radar was mounte don a tripod, fixed on the roof at the rear of the vehicle. The monitoring equipment and etra batteries were stored inside the compartment, which had a single occupied bench and a small table. The ZB 298 combat field surveillance radar was made by British Marconi Avionics, and it operated in the 3 cm band. It could detect any infantry up to 5 km and vehicles up to 10 km. The tripod could also be dismounted, and remotelly operated from the vehicle at a short distance if needed. One of the two operators also served as a gunner.The inside was divided, to the right it was the same as the standard APC version, but the left was entirely dedicated to radar equipment with suspension points and racks for cables and peripherals. The latter consisted of a large cabinet with display and headphones worked on sound recognition as it was a doppler. It carried extra gear such as the navigation, compass alignment system to level the radar and a battery tray, to expand the radars eight. The vehicle was also given two radio sets and the same heater as in the CO vehicle, mainly intended to keep the radar equipment at an even temperature. The vehicle was mostly stationary and carried for deployment camouflage nets and tubing externally.

More special versions

Were also developed abut a dozen sub-variants mosty for testing:-DAF YP104: The 1958 initial 4x4 "Daimler Scout" like recce vehicle, on which was developed the 6x8 version.

-DAF YP406: A 6x6 version, a vehicle developed at the suggestion of Dr van Doorne, in order to have it tested by the Inspection Technical Service. The second axle was removed and the rear axle had both wheelset placed 35 cm forward for balance. Blueprint

-YPX Test Bed: An an experimental vehicle with 2 custom trado sets, Detroit V6 cyl. 2-stroke diesel for drivers to test the “skip” technique to make tighter turns. Woodedn body over a soft steel frame.

-DAF YP408 106 mm TLV. This was a testebed for the M40a1 recoiless rifle, alternative to ATGMs. The latter replaced the HMG mount. Tested 1934-71.

-8-wheel DAF YA 328: A truck based on the YP-408 chassis. Ref

Exports

Suriname: A number were passed onto the new Surinamese army when the country became independent in 1975 (formerly under Dutch rule). These were called "TRIS": 5 vehicles which replaced in Suriname the Canadian Otter from January 1972, were disembarked at Paramaribo and later armed with a Bren .303. Portugal also leased some for their air force police before the year 2000.Service

Together with the AMX PRI, the YP-408 served in the Dutch Army motorized infantry between 1965 and 1986. Until 1989, the vehicle was either resold or replaced by the YPR 765 tracked IFV under licence and more recently in part by the LGS Fennek.

Despite strict loading lists, a fully equipped vehicle is never set up in accordance with all regulations, especially for exercise, unnecessary equipment remained under lock and key in the barracks. The infrared night vision equipment was one of these, as well as rolls of barbed wire, boxes of hand grenades, and ammunition in general. Fire extinguishers and first-aid kits are also rarely carried in. Vacant spaces were packed by unregulated duffel bags with extra clothing, extra emergency rations or even air mattress and pump. Outside, blanket rolls, sleeping bags, camouflage nets were all tied to the roof, wrapped intor a waterpoof canvas. As of today, after their retirement in 1993 and thanks to passionate people, with the exception of wrecks, 31 vehicles are still in existence, of which 27 for Netherlands alone, notably the instruction vehicles. Some Suriname vehicles (5 and later 9) are mostly still running. One is in France (Saumur Museum), one in Belgium, one in Bovington, UK. In the Netherlands, 15 are still in running order and regaularly participated to events. Six are privately owned with civil registration plates.YP-408 specifications | |

| Dimensions | 5.26 x 2.82 x 2.62m (17.2 x 9.25 x 8.59 ft) |

| Total weight, battle ready | 13.6 tons (27.200 Ibs) |

| Crew | 3+7 (driver, cdr, gunner, 7 infantry) |

| Propulsion | Detroit Diesel Allison 6V-53T 267 hp (195 kW) P/w 19.29 hp/t |

| Suspension | Torsion bars |

| Speed (road) | 61 km/h (38 mph) |

| Range | 490 km (305 mi) |

| Armament | 20mm KBA-B02 cannon, coaxial FN-MAG 7.62mm |

| Armor | Protection against small arms fire +spaced armor |

| Total production | 815 in 1975-1980 |

Part I: https://youtu.be/5YF4MC1_Dcg

Part II: https://youtu.be/Y7N2CyBpft4

Sources

https://www.dafyp408.nl/talen/english.htmlhttps://en.wikipedia.org/wiki/DAF_YP-408

https://www.dafyp408.nl/ http://www.warwheels.net/DAFyp408INDEX.html

Basic YP-408 APC version

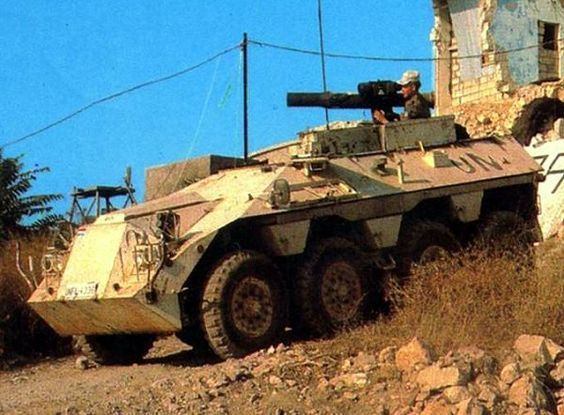

YP-408 used in peace keeping operation with UN livery

YP-408-PWGWT, Ambulance vehicle

YP-408 PWMT, mortar version (not shown here)

YP-408 PWAT, antitank version

Gallery

YP-408 KN-90 Bridgehead 2011.

DAF YP408 1968 owned by Timo Pronk.

Ambulance version UNIFIL 2011

Naked Chassis.

YP-408 in Lebanon.

Vehicle of the Dutch-Contingent in Lebanon

PWAT version with camouflage.

"Cobra" in Suriname.

TLV1 Recoiless Rifle version prototype.

YP-408 CC

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army