The Merkava Mark 3 is an Israeli main battle tank, third in series and retaining the architecture of its predecessors with a front-mounted engine, but it really was a 2nd generation tank, sharing no components whatsoever with the Mark 1 and 2 apart the gearbox. Development started in 1984 under the supervision of Israel Tal, and the prototype was unveiled on May 14, 1987 (Memorial Day), entering service with the 188th Armored Brigade "Barak" in 1990 and replacing the existing Sho't as well as the 7th Armored Brigade's Merkava 2s. The Mark 3 remained in service until July 2020 in the 188th. AB. Morocco and Cyprus expressed interest in acquisiring these tanks in depot, but with the events in Palestine it was decided to retain these.

There were two priorities in the design, first to develop a home-grown tank gun, and a new generation passive protection taking in account all previous wars, and the Lebanon crisis from 1982 onwards. The calculated weight quickly showed as well that the initial Teledyne Continental AVDS-1790-7A V12 air-cooled diesel engine which developed 950 hp (708 kW) would not be enough to power a machine likely to jump from 62 to 63 tonnes (the final weight was 63.5 tonnes). The development lasted from 1984 to 1987 when the prototype was unveiled.

The Merkava 3 started from a blank page and eliminated all what made the Mark 1 and 2 still sharing a lot of elements with the Sho't (Israeli Centurion). The hull for example was built anew, not only to integrate new passive composite and ERA armour elements, but also a new suspension system to cope with the extra weight. In the end, all mechanical emlements, equipments, the hull and turret design were completely redone. The tanks would be brand new, and not recycled Mark 1/2s. The design stages comprised a mockup, probably showcased to the authorities by Israel Tal in 1985, and two years of work on a first prototype.

The Merkava 3 prototype was officially unveiled the 14 may 1987 Yom Haʿatzmaout (independence day) celebration and parade. It was showcased on a truck trailer, not running yet. However trials proceeded all along the remainder of 1987 and around mid-1988 for fixes and new trials, until the model was greenlight for production probably by late 1989.

The final prototype was tested and approved for service in December 1989. Production was entirely retooled at MANTAK since the new vehicle only shared its Renk gearbox with the original. The first Merkava 3 rolled of the factory by late 1990 and the first batch was sent stright to the elite armoured unit of the IDF, the 188th Brigade "Barak". Production then would go on until 2002, so twelve years, wit an unprecedented 780 tanks, almost as much as the Mark 1 and 2 combined (830). So far this is the largest production for the Merkava. The series 4 saw a more modest 360 vehicles delivered (still ongoing). The Merkava 3 shares its basic layout with the previous marks, notably the iconic front-mounted engine, as a way to protect the crew, in addition of the armour placed on the nose. The driver's position was retained, bethind the transverse-mounted power unit and transmission, to the right of the drive, still on the left, with a position right below the turret's nose. To enter and exit via his hatch, the turret needed to be turned. However, the usual way to access the vehicle remained the same as before for the crew of four, with the turret counting a commander, gunner and loader as well. They all entered and exited the vehicle through a back hull door, which was possible due to the front-mounted engine and which presented a small space to accept two more men if needed.

The Merkava 3 shares its basic layout with the previous marks, notably the iconic front-mounted engine, as a way to protect the crew, in addition of the armour placed on the nose. The driver's position was retained, bethind the transverse-mounted power unit and transmission, to the right of the drive, still on the left, with a position right below the turret's nose. To enter and exit via his hatch, the turret needed to be turned. However, the usual way to access the vehicle remained the same as before for the crew of four, with the turret counting a commander, gunner and loader as well. They all entered and exited the vehicle through a back hull door, which was possible due to the front-mounted engine and which presented a small space to accept two more men if needed.

The general philosophy behind the front-mounted engine was a combination of several factors, but the most important was crew's survivability. Statistics showed tanks were likely to be hit frontally, so the engine mass and its sheer complexity would bring an extra protection to the crew. The losses in 1973 were a burning souvenir, and it was decided that a country sthat small as Israel could not waste an entire generation of well-trained tankers. The vehicles were less important than their crews. A position diametrally opposed to their arab neighbours that along with their soviet tanks professed a doctrine in which both the tanks and crews were expandable.

But experience from the 1973 and 1982 war, two years before starting development, showed that the Mark 1/2 were not immune to the latest ATGMs or even RPG types and so focus was on the design of a brand new composite armour, following a trend started in the 1970s with the Challenger, Leopard 2, and in 1976-77 with the M1 Abrams, truly a second generation MBTs. The Soviet T72 was now replacing the T-54/55 and also integrated composite armour elements, acquired en masse by Arab countries surrounding Israel. Composite enabled to save weight why procuring a better and more modular approach to protection, especially to face the last generation 125mm AP, HESH and HEAT rounds in inventory. This made the new tank one and half ton heavier than its predecessor.

The other part of the equation was the gun, not only to dispose of the Rheinmetall licence but also to develop at home a new generation of ammunitions, the development of the brand new 120 mm smoothbore tank gun was prioritized. To keep performances up, the new tank was also to be powered by a new 1,200 horsepower engine, filling the main battle tank sacred trilogy with a good balance.

The Merkava Mk. 3 was built in three production batches with the first two (3A) featuring only minor internal modifications. Batch 3 (Mk.3B) featured composite over-armor on the turret roof, composite armor module on the turret sides at the height of the thickened 127 mm (5 inches) magazine, circular cast steel turret base replaced by a smaller, welded base. The magazine hatch featured a new circular flap and modified mount for the 60 mm mortar. Some Mk. 3s received also an improved CBRN filtration system with the new "Yoni" air conditioning system, with one vent per station. They were distinct by their larger air intake grilles on the chassis.

The chassis is also 15 cm longer than its predecessor to make for two larger fuel tanks located on either side of the redesigned rear door. There is also a floor valve opening outward in the event of overpressure after a projectile penetration. The fuel thus drains under the tank, preventing it from spilling into the crew compartment and ignite. The CBRN filtration system was relocated to the base of the turret.

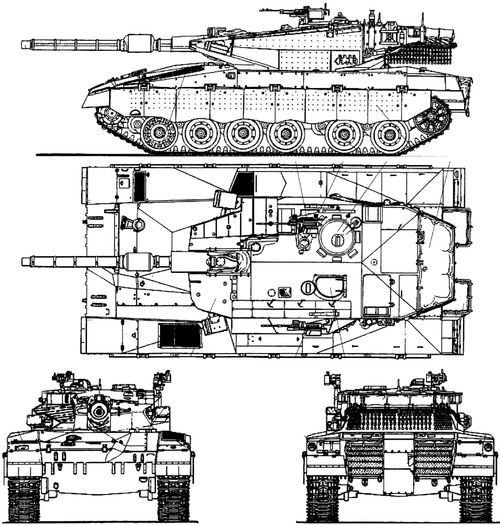

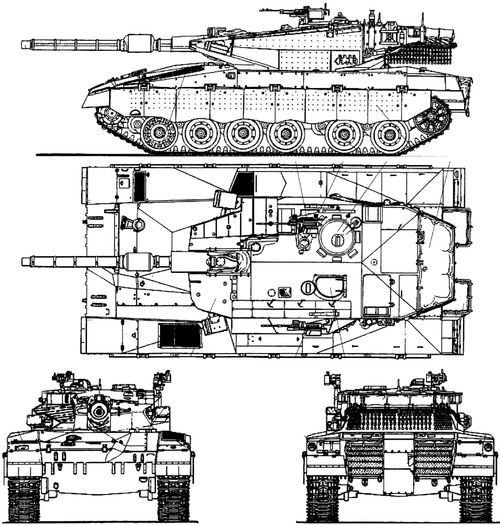

This turret was asymetric and a bit longer than on the Mark 2, and presented two distinct "corners" on the front, on the right (when facing the tank), a cutout with a fire control sight for the gunner at its end, then a central "tunnel" in which the elevation mechanism and pivot of the main gun was installed, and then a thicker left wedge for the caxial MG and secondary sight. The wedge-shape of the turret seen from its side presented a gradual slope up to 2/3 its lenght, paved with composite panels, removable side panels, and lower extensions acting both as spaced armour and storage bins.

The flat section at the rear of the turret was topped by blow-out panels for the ammunition magazines. The back tip was fitted with a storage pannier and a curtain of metal balls to detonate shape-charged RPGs rockets or ATGMs and protect the turret's rear shot trap. The rear section devoid of any engine was filled with extra ammunition, fuel and extra space fo the personal's own gear. The two cupolas for the loader an commander were side by side at the rear of the turret, each with an articulated ring mount for a standard MAG machine gun. There was an extra fitting for a remotelly activated M2HB heavy machine gun above the barrel forward, and an interlally loaded and fire mortar on the right side.

The Merkava Mk. 3 was indeed the world's first tank to feature modular composite armor with removable armor plating covering the front and sides of the turret, glacis, and the hull overhanging above the tracks. The fuel tanks, previously located in the false bottom of the Mk. 1 and Mk. 2 hulls were removed due to the shockwaves generated by IEDs being a hazard in that location. These schockwaves spreads more easily through a liquid than through air. Part of the active protection rested on three Amorcam LIW-2 laser warning detectors at the front and on each side of the turret, providing a visual or audio alarm when targeted by a ranging or guidance laser. The two IS-6 grenade launchers (six 78.5 mm smoke grenades each) are used for smoke concealment but can also fire anti-personal grenades, part of the IMI CL-3030 close-in defence system.

The Modular armor present on the hull and turret were brand new and facilitated repair accelerated recovery of damaged tanks as they were al removed quickly, or later upgrades. The Lebanon war proved the effectiveness of the crew entry or exit from the rear in a "corridor" between the aft drivetrain, providing several tactical advantages when cooperating with infantry. Automatic Halon fire extinguishers were installed on the engine compartlent and combat compartment plus a sprinkler in the turret bustle to avoid cookoffs.

Also inspired by the 1982 Lebanon war, the internal mortar was capable of firing a variety of ammunition, including illumination shells. Passive protection also comprised an NBC system, albeit it was mostly a benefit of the air conditioning, really appreciated under these latitudes, and for active protection, two sets of smoke projectors either side of the turret's nose. There was a sensor mast for later version installed on the right rear of the turret as well.

The Mark 3 received an air-cooled V12, 29.3L diesel Teledyne Continental AVDS-1790-9AR rated for 1 200 ch (882,5 kW) at 2,400 rpm, coupled with a Renk RK 304 automatic transmission (4 fwd/2 rvs). Torque is 3,820 Nm at 1,900 rpm. This new powerplant was to compensate the extra tons of the design. The suspension system was composed of vertical coil springs and rotary hydraulic dampers, with two single pin tracks, rubber-cladded rolled by six wheels made of doubled stamped roadwheels, four return rollers per side. Since the engines was at the front, the drive sprockets were a the nose and idlers aft.

The new long-travel suspension and its rotary hydraulic shock absorbers saw the coil springs no longer coupled to the suspension arms but simply rest on them to significantly increases the travel in the rebound phase, of 300 mm in compression, 300 mm in rebound, 600 mm in all. On the Mk. 3 Baz, the track rollers do not have the rubberized tires as the rocky terrain of the Golan Heights is very destructive for this type of surface, so they were simply removed. The Mk. 3 also introduced a new set of tracks, wider with a the spacing between track rollers revised to better distribute the mass.

The AVDS-1790-9AR is a modified version of AVDS-1790-9A with a different cooling system and oil filters. The combat load average top speed is 55 km/h but the prototype and the first pre-production models, unladen, rached 58 km/h with a power to weight ratio of 18,8 hp/t. The Merkava 3 fuel tanks holds 1,100 liters total making for a range of 500 km. This chassis was designed to withstand the harsh terrain conditions of the Golan Heights. The smoothbore gun MG251 was essentally a rebored version of the Rheinmetall of the previous Marks, with a diameter increased as developed and manufactured by IMI. Externally still it was roughly similar to the 120 mm L44 from Rheinmetall. It was tailored to fire 120 mm shells developed in Israel, but can also fire 120 mm NATO shells. The firing system, cannon, and ammunition are more or less equivalent to their most modern American and European counterparts. Being 44 calibers (5,280 mm) long thus smoothbore gun also features a fume extractor, and is covered with an anti-arching sleeve.

The smoothbore gun MG251 was essentally a rebored version of the Rheinmetall of the previous Marks, with a diameter increased as developed and manufactured by IMI. Externally still it was roughly similar to the 120 mm L44 from Rheinmetall. It was tailored to fire 120 mm shells developed in Israel, but can also fire 120 mm NATO shells. The firing system, cannon, and ammunition are more or less equivalent to their most modern American and European counterparts. Being 44 calibers (5,280 mm) long thus smoothbore gun also features a fume extractor, and is covered with an anti-arching sleeve.

The magazine holds five ready-to-fire rounds. They are located in a sealed, armored drum, mounted on the floor. This rotating drum is operated by the loader via a foot pedal, to present the round to be loaded into the breech. This system ensures no round is exposed inside the tank. The remaining 120 mm ammunition are stored in individual fireproof containers, four positioned vertically against the engine compartment firewall, the remaining thirty-six in the rear compartment, on either side of the gull-wing door.

This was completed by the "usual suspects", two 7.62 mm MAG light machine guns on flexible arms over the two rear roof cupolas (1000 rds) and a Browning cal.50 over the gun mantlet forward. This was completed by a 60mm commando mortar, loaded inside, firing from the roof, with between 24 and 30 shells, mostl anti-personal. The fire control for the main gun rests on the gunner's sight, stabilized on both planes. The day view has a magnification of 12x, the thermal view a magnification of 5x and it has an automatic target tracking system Knight Mk.3. The Mk. 3 Baz version adds to this a true panoramic commander's sight with thermal imaging.

Development and design of the Merkava III

Unlike previous mark 1 and 2s which shared many elements with the Sho't (Israeli Centurion), it was decided by a new consortium tasked of the first design studied back in 1984, MANTAK (Merkava Tank Office). The latter was created undeer the lead of veteran tank commander Israel Tal, as both a designer office and manufacturing, starting work and production of the Mark 1 back in 1979 and Mark 2 from 1983, manufactured until 1989 to 580 vehicles. So design for its successor started as soon as the Mark 2 entered production.There were two priorities in the design, first to develop a home-grown tank gun, and a new generation passive protection taking in account all previous wars, and the Lebanon crisis from 1982 onwards. The calculated weight quickly showed as well that the initial Teledyne Continental AVDS-1790-7A V12 air-cooled diesel engine which developed 950 hp (708 kW) would not be enough to power a machine likely to jump from 62 to 63 tonnes (the final weight was 63.5 tonnes). The development lasted from 1984 to 1987 when the prototype was unveiled.

The Merkava 3 started from a blank page and eliminated all what made the Mark 1 and 2 still sharing a lot of elements with the Sho't (Israeli Centurion). The hull for example was built anew, not only to integrate new passive composite and ERA armour elements, but also a new suspension system to cope with the extra weight. In the end, all mechanical emlements, equipments, the hull and turret design were completely redone. The tanks would be brand new, and not recycled Mark 1/2s. The design stages comprised a mockup, probably showcased to the authorities by Israel Tal in 1985, and two years of work on a first prototype.

The Merkava 3 prototype was officially unveiled the 14 may 1987 Yom Haʿatzmaout (independence day) celebration and parade. It was showcased on a truck trailer, not running yet. However trials proceeded all along the remainder of 1987 and around mid-1988 for fixes and new trials, until the model was greenlight for production probably by late 1989.

The final prototype was tested and approved for service in December 1989. Production was entirely retooled at MANTAK since the new vehicle only shared its Renk gearbox with the original. The first Merkava 3 rolled of the factory by late 1990 and the first batch was sent stright to the elite armoured unit of the IDF, the 188th Brigade "Barak". Production then would go on until 2002, so twelve years, wit an unprecedented 780 tanks, almost as much as the Mark 1 and 2 combined (830). So far this is the largest production for the Merkava. The series 4 saw a more modest 360 vehicles delivered (still ongoing).

Design of the Merkava Mark 3

General Layout

The Merkava 3 shares its basic layout with the previous marks, notably the iconic front-mounted engine, as a way to protect the crew, in addition of the armour placed on the nose. The driver's position was retained, bethind the transverse-mounted power unit and transmission, to the right of the drive, still on the left, with a position right below the turret's nose. To enter and exit via his hatch, the turret needed to be turned. However, the usual way to access the vehicle remained the same as before for the crew of four, with the turret counting a commander, gunner and loader as well. They all entered and exited the vehicle through a back hull door, which was possible due to the front-mounted engine and which presented a small space to accept two more men if needed.

The Merkava 3 shares its basic layout with the previous marks, notably the iconic front-mounted engine, as a way to protect the crew, in addition of the armour placed on the nose. The driver's position was retained, bethind the transverse-mounted power unit and transmission, to the right of the drive, still on the left, with a position right below the turret's nose. To enter and exit via his hatch, the turret needed to be turned. However, the usual way to access the vehicle remained the same as before for the crew of four, with the turret counting a commander, gunner and loader as well. They all entered and exited the vehicle through a back hull door, which was possible due to the front-mounted engine and which presented a small space to accept two more men if needed.

The general philosophy behind the front-mounted engine was a combination of several factors, but the most important was crew's survivability. Statistics showed tanks were likely to be hit frontally, so the engine mass and its sheer complexity would bring an extra protection to the crew. The losses in 1973 were a burning souvenir, and it was decided that a country sthat small as Israel could not waste an entire generation of well-trained tankers. The vehicles were less important than their crews. A position diametrally opposed to their arab neighbours that along with their soviet tanks professed a doctrine in which both the tanks and crews were expandable.

But experience from the 1973 and 1982 war, two years before starting development, showed that the Mark 1/2 were not immune to the latest ATGMs or even RPG types and so focus was on the design of a brand new composite armour, following a trend started in the 1970s with the Challenger, Leopard 2, and in 1976-77 with the M1 Abrams, truly a second generation MBTs. The Soviet T72 was now replacing the T-54/55 and also integrated composite armour elements, acquired en masse by Arab countries surrounding Israel. Composite enabled to save weight why procuring a better and more modular approach to protection, especially to face the last generation 125mm AP, HESH and HEAT rounds in inventory. This made the new tank one and half ton heavier than its predecessor.

The other part of the equation was the gun, not only to dispose of the Rheinmetall licence but also to develop at home a new generation of ammunitions, the development of the brand new 120 mm smoothbore tank gun was prioritized. To keep performances up, the new tank was also to be powered by a new 1,200 horsepower engine, filling the main battle tank sacred trilogy with a good balance.

The Merkava Mk. 3 was built in three production batches with the first two (3A) featuring only minor internal modifications. Batch 3 (Mk.3B) featured composite over-armor on the turret roof, composite armor module on the turret sides at the height of the thickened 127 mm (5 inches) magazine, circular cast steel turret base replaced by a smaller, welded base. The magazine hatch featured a new circular flap and modified mount for the 60 mm mortar. Some Mk. 3s received also an improved CBRN filtration system with the new "Yoni" air conditioning system, with one vent per station. They were distinct by their larger air intake grilles on the chassis.

The chassis is also 15 cm longer than its predecessor to make for two larger fuel tanks located on either side of the redesigned rear door. There is also a floor valve opening outward in the event of overpressure after a projectile penetration. The fuel thus drains under the tank, preventing it from spilling into the crew compartment and ignite. The CBRN filtration system was relocated to the base of the turret.

Turret

The turret design was also changed, notably by disposing of the round "ears" on the Marks 1 and 2. The shapes were completely renewed to decrease passive armour slightly by increasing angles, while keeping pace woth the interior design that had to cope with a slightly larger tank gun, and better egonomics as whole. The turret presented an even more angular and narrow front, presdenting no "face" to an incoming round while finding solutions to avoid shot traps. Around it was wrapped a brand new and innovative sloping modular armor covering both sides, called the KS3 after the purple line.This turret was asymetric and a bit longer than on the Mark 2, and presented two distinct "corners" on the front, on the right (when facing the tank), a cutout with a fire control sight for the gunner at its end, then a central "tunnel" in which the elevation mechanism and pivot of the main gun was installed, and then a thicker left wedge for the caxial MG and secondary sight. The wedge-shape of the turret seen from its side presented a gradual slope up to 2/3 its lenght, paved with composite panels, removable side panels, and lower extensions acting both as spaced armour and storage bins.

The flat section at the rear of the turret was topped by blow-out panels for the ammunition magazines. The back tip was fitted with a storage pannier and a curtain of metal balls to detonate shape-charged RPGs rockets or ATGMs and protect the turret's rear shot trap. The rear section devoid of any engine was filled with extra ammunition, fuel and extra space fo the personal's own gear. The two cupolas for the loader an commander were side by side at the rear of the turret, each with an articulated ring mount for a standard MAG machine gun. There was an extra fitting for a remotelly activated M2HB heavy machine gun above the barrel forward, and an interlally loaded and fire mortar on the right side.

Protection

Emphasis in the vehicle's protection was on crew survivability, still with the engine located at the front and well protected hull on the front and sides. The nose was asymetrical, due to the transverse engine and placement of the tranmission, and festooned with composite panels and servicing access hatches. Exhausts were on the left side. Above the tracks were located extra storage compartments, and the drive train was protected by five divided rigid panels of the new design, fitted with bolts for spaced and composite panels.The Merkava Mk. 3 was indeed the world's first tank to feature modular composite armor with removable armor plating covering the front and sides of the turret, glacis, and the hull overhanging above the tracks. The fuel tanks, previously located in the false bottom of the Mk. 1 and Mk. 2 hulls were removed due to the shockwaves generated by IEDs being a hazard in that location. These schockwaves spreads more easily through a liquid than through air. Part of the active protection rested on three Amorcam LIW-2 laser warning detectors at the front and on each side of the turret, providing a visual or audio alarm when targeted by a ranging or guidance laser. The two IS-6 grenade launchers (six 78.5 mm smoke grenades each) are used for smoke concealment but can also fire anti-personal grenades, part of the IMI CL-3030 close-in defence system.

The Modular armor present on the hull and turret were brand new and facilitated repair accelerated recovery of damaged tanks as they were al removed quickly, or later upgrades. The Lebanon war proved the effectiveness of the crew entry or exit from the rear in a "corridor" between the aft drivetrain, providing several tactical advantages when cooperating with infantry. Automatic Halon fire extinguishers were installed on the engine compartlent and combat compartment plus a sprinkler in the turret bustle to avoid cookoffs.

Also inspired by the 1982 Lebanon war, the internal mortar was capable of firing a variety of ammunition, including illumination shells. Passive protection also comprised an NBC system, albeit it was mostly a benefit of the air conditioning, really appreciated under these latitudes, and for active protection, two sets of smoke projectors either side of the turret's nose. There was a sensor mast for later version installed on the right rear of the turret as well.

Powerplant and Performances

The Mark 3 received an air-cooled V12, 29.3L diesel Teledyne Continental AVDS-1790-9AR rated for 1 200 ch (882,5 kW) at 2,400 rpm, coupled with a Renk RK 304 automatic transmission (4 fwd/2 rvs). Torque is 3,820 Nm at 1,900 rpm. This new powerplant was to compensate the extra tons of the design. The suspension system was composed of vertical coil springs and rotary hydraulic dampers, with two single pin tracks, rubber-cladded rolled by six wheels made of doubled stamped roadwheels, four return rollers per side. Since the engines was at the front, the drive sprockets were a the nose and idlers aft.

The new long-travel suspension and its rotary hydraulic shock absorbers saw the coil springs no longer coupled to the suspension arms but simply rest on them to significantly increases the travel in the rebound phase, of 300 mm in compression, 300 mm in rebound, 600 mm in all. On the Mk. 3 Baz, the track rollers do not have the rubberized tires as the rocky terrain of the Golan Heights is very destructive for this type of surface, so they were simply removed. The Mk. 3 also introduced a new set of tracks, wider with a the spacing between track rollers revised to better distribute the mass.

The AVDS-1790-9AR is a modified version of AVDS-1790-9A with a different cooling system and oil filters. The combat load average top speed is 55 km/h but the prototype and the first pre-production models, unladen, rached 58 km/h with a power to weight ratio of 18,8 hp/t. The Merkava 3 fuel tanks holds 1,100 liters total making for a range of 500 km. This chassis was designed to withstand the harsh terrain conditions of the Golan Heights.

Armament

The smoothbore gun MG251 was essentally a rebored version of the Rheinmetall of the previous Marks, with a diameter increased as developed and manufactured by IMI. Externally still it was roughly similar to the 120 mm L44 from Rheinmetall. It was tailored to fire 120 mm shells developed in Israel, but can also fire 120 mm NATO shells. The firing system, cannon, and ammunition are more or less equivalent to their most modern American and European counterparts. Being 44 calibers (5,280 mm) long thus smoothbore gun also features a fume extractor, and is covered with an anti-arching sleeve.

The smoothbore gun MG251 was essentally a rebored version of the Rheinmetall of the previous Marks, with a diameter increased as developed and manufactured by IMI. Externally still it was roughly similar to the 120 mm L44 from Rheinmetall. It was tailored to fire 120 mm shells developed in Israel, but can also fire 120 mm NATO shells. The firing system, cannon, and ammunition are more or less equivalent to their most modern American and European counterparts. Being 44 calibers (5,280 mm) long thus smoothbore gun also features a fume extractor, and is covered with an anti-arching sleeve.

The magazine holds five ready-to-fire rounds. They are located in a sealed, armored drum, mounted on the floor. This rotating drum is operated by the loader via a foot pedal, to present the round to be loaded into the breech. This system ensures no round is exposed inside the tank. The remaining 120 mm ammunition are stored in individual fireproof containers, four positioned vertically against the engine compartment firewall, the remaining thirty-six in the rear compartment, on either side of the gull-wing door.

This was completed by the "usual suspects", two 7.62 mm MAG light machine guns on flexible arms over the two rear roof cupolas (1000 rds) and a Browning cal.50 over the gun mantlet forward. This was completed by a 60mm commando mortar, loaded inside, firing from the roof, with between 24 and 30 shells, mostl anti-personal. The fire control for the main gun rests on the gunner's sight, stabilized on both planes. The day view has a magnification of 12x, the thermal view a magnification of 5x and it has an automatic target tracking system Knight Mk.3. The Mk. 3 Baz version adds to this a true panoramic commander's sight with thermal imaging.

Variants

Mark 3 MPS (1990)

A basic first version using a fire control system similar to that of the Merkava Mark 2. The MPS was also known as the Mark 3 RMAH (acronym for "Electric Mirror Head", named after the technology). It entered service in 1990, with the first batches. On the Mk.3B (1994), the turret roof is covered with composite over-armor. The loader hatch flap is redesigned and circular. The composite armor module protecting the turret sides at the height of the loader is thickened to 127 mm (5 inches) with the circular cast steel base being made more compact, welded. The 60 mm mortar also has its mount modified.Mark 3 BZ (1995)

The Barak Zohar (BZ) version had the new, namesake fire control system, entering service in 1995. The firing capability on the move and locking on a moving target with 3-axles stabilization are setup. In 1997, a sub-version of the BZ entered service with a new air conditioner and the same year, the Israel Defense Prize was awarded for the development of this cambat system.Mark 3 KSG (1998)

Merkava 3 Kav Sagol (KSG): Improved protection for the northern theatern modular and compatible with earlier Mark 3 versions.Mark 3D BZ

Merkava Mark 3D BZ: The most advanced upgrade to the Barak Zohar with a new digital command and control system, improved protection, modular armor additions, new air conditioning system and active protection against airborne ATGMs and more.Mark 3D LIC

The Merkava Mark 3 LIC (Low Intensity Combat) was the 3D BZ converted for urban combat and limited asymetric threats. It has mesh shields against hand grenades, better vision and global awareness for the driver, plus a remotelly controlle M2 Browning 0.5 heavy machine gun via electric gear, plus a sniper position in the rear corridor.Mark 3M

The Merkava Mark 3M is an evolution of the 3D BZ with the "Windbreaker" active tank protection system. Budgetary and logistical considerations led to never purchase it. However, it remained listed as option for export upgrades (see below).Criticism

The Merkava 3 power/weight ratio was seen unfavourably compared the Abrams M1A2, both in top speed and acceleratons, the Merkava is just way slower, which was especially evident against the Merkava Mark 4. The Mark 3 indeed originally did not saw speed as a focus, as it was designed for combat in rocky terrain, the Golan Heights instead of the plains or open desert of the European and American tanks. The Merkava was also criticized in the 2010s for its lack of advanced features such as a built-in satellite navigation system and displays for battlefield awareness among others.Merkava Mk. 3 specifications | |

| Dimensions (l-w-h): | 7,60(9,63 m gun) x 3,70 m x 2,65 m |

| Total weight, battle ready: | 63,5-65 tonnes |

| Crew : | 4 (Driver, Gunner, Commander, Loader) |

| Propulsion: | Diesel AVDS-1790-9AR 1200 hp (885 kW), 18,8 hp/t |

| Suspensions: | Torsion arms |

| Top Speed | 58 kph ( mph) 40-45 kph off-road |

| Range (road)/Fuel consumption | 500 km ( mi) |

| Armament (see notes) | MG251 120 mm, 3x 7,62 mm (0.3 in) LMGs |

| Armour | Modular, ERA, see notes. |

| Total Production | 780 |

Active Service

The Merkava 3A entered service with the 188th Armored Brigade "Barak" in 1990, where it replaced the last Sho't still in service, and the 7th Armored Brigade, to replace Merkava Mk. 2s. Following the Second Intifada, a number of Merkava 3 were converted for urban combat with a M2 Browning 0.5 above the barrel, remotelly operated from the turret, video cameras, a rear sniper position and grenade-resistant mesh armour as the "LIC".The Merkava 3 was used in Operation Rainbow in Rafah and the Second Lebanon War, in which several were converted as frontline ambulances; able to evacuate wounded soldiers under fire. By late 2018 and early 2021, the IDF started converting decommissioned Merkava Mark 2 and Mark 3s or earlier batches into heavy combat support tanks like the Ofek and Parag. By late July 2020, the last Merkava Mk. 3s still in service with the 188th Armored Brigade were replaced by Merkava Mk. 4s.

In November 2023, following the Iron Swords War and increasing demand for tanks, new units were established, and many tanks were returned to service in the various units. By 2023, the International Institute for Strategic Studies estimated 700 Merkava 3 still in stock. This summer, Morocco announced its intention to acquire 200 of them, as did Cyprus, the later to replace their 83 Russian T-80 tanks. If agreed, these would have been the first exports in this series. But negociations were suspended in October 2023, following the war in Gaza. The Israeli government reportedly decided to equip reserve units with these depot tanks. The Morocccan dea was estimated to be worth $1.2 billion. The Merkava 3 returend into service, are part of the Phoenix unit.

Gallery

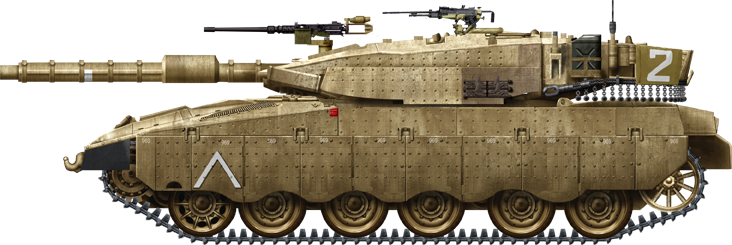

Merkava 3 188th Tank Brigade "Barak" 1990.

Tank of the Combat Training Center 1990-91

Command Tank 2nd Platoon, 3rd Gimel Company, 1st Sufa(Stom) Batallion 188 Barak Brigade.

Tank 1 Alef, 1st Platoon 1st Company, 3rd Lzuz (Bravery) Batallion, 460 Brigade. Operation Cast Lead Gaza Jan 2009

More to come...

Prototype at Latrun Museum

Marl3BZ_Armored_Brigade_Drill_in_the_Golan_Heights

Links/Src

James Bruce, « Public unveiling for Israeli Merkava III », Jane's Defence Weekly, vol. 7, 28 mars 1987Michael Mass, Merkava Siman 3 : Merkava Mk 3 in IDF service part 1, Desert Eagle Publishing, 2007

Marsh Gelbart, Modern Israeli Tanks and Infantry Carriers 1985-2004, Osprey Publishing, 2004

Marc Chassillan, « Le Merkava », Raids Hors-Série N°3, 2001, p. 17

Marsh Gelbart, Modern Israeli Tanks and Infantry Carriers 1985-2004, Osprey Publishing 2004

CC images

army-technology.com

army-guide.com

armyrecognition.com

he.wikipedia.org

fr.wikipedia.org

Merkava 3D

Cold War Tanks

Cold war tanks posters

Cold War Main Battle Tanks

Cold War Soviet Army

Museums, Movies, Books & Games

The Tanks and Armor in pop culture

Tanks and armored vehicles in general are only really grasped when seen first person: The mass, the scale, it's all there. Explore also the way tanks were covered in the movie industry, in books and in video games.Movies:

Best tanks movie on warhistoryonline.com

On imdb.com

On bestsimilar.com/

miltours.com

liveabout.com/

watchmojo.com

Video Games:

pcgamesn.com

historyhit.com

levvvel.com

vg247.com/best-tank-games

mmobomb.com/

alienwarearena.com